Dragging twist-resistant metallic shield flexible cable for mining equipment

A technology of mining equipment and metal shielding, which is applied to power cables with shielding layers/conductive layers, bendable cables, insulated cables, etc., and can solve the problem of loss of monitoring protection, easy breakage of cable control cores, and breakage of control wire cores And other problems, to achieve the effect of not easy to break the core, improve the relative sliding performance, and improve the bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

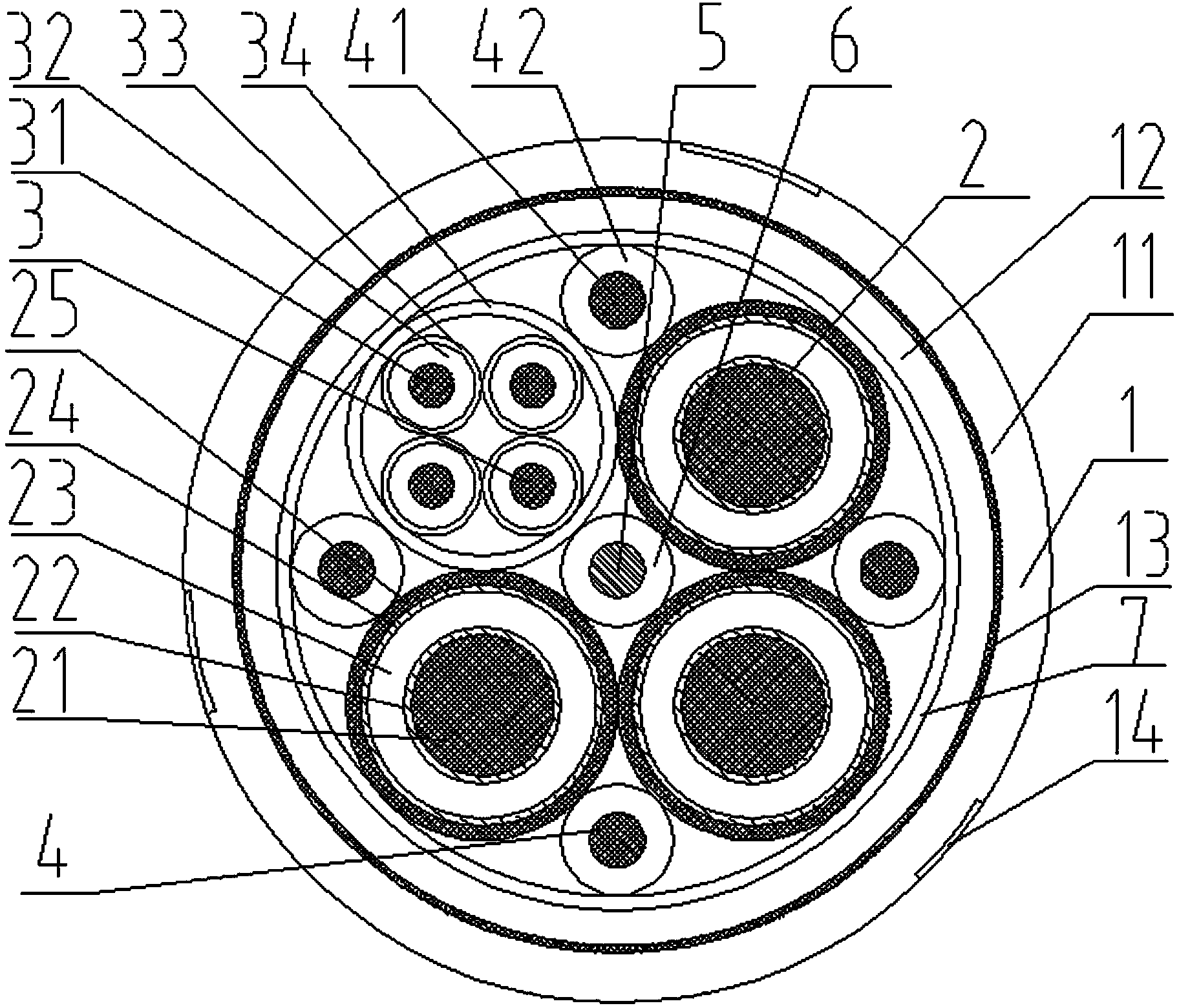

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] Such as figure 1 As shown, the present invention includes a protective cover 1, three power cores 2, four control cores 3, four ground cores 4 and a high-strength fiber 5, and the high-strength fiber 5 is located in the center of the protective cover 1 .

[0029] The control wire core 3 is composed of a conductor 31 and a high-elastic rubber insulating layer 32 wrapped outside it and a heat-resistant thin slip belt layer 33. The high-elastic rubber insulating layer 32 is located between the conductor 31 and the heat-resistant thin slip belt layer. Between 33. The four control wire cores 3 are twisted together in the same direction and wrapped in a layer of heat-resistant thin slip tape 34 to form a control cable. The outer surfaces of the control wire cores 3 are all heat-resistant thin slipping tape layers 33, and the four control wire cores 3 are wrapped in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com