Web member intersecting and split joint connector structure in positions of steel truss girder bridge nodes

A steel truss bridge and crossover technology, applied in truss bridges, bridges, bridge forms, etc., can solve the problems of welding fatigue, excessive stress concentration, etc., and achieve the effect of saving steel, reducing size, and achieving remarkable effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

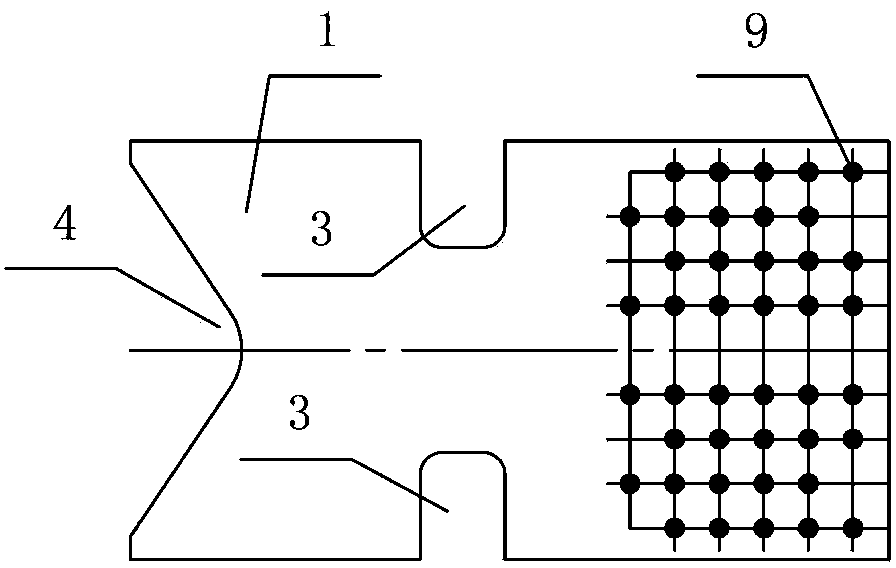

[0015] refer to figure 1 , There are U-shaped grooves-3 on both sides of the splicing joint plate-1 of the present invention, a dovetail groove 4 at the tail, and high-strength bolt holes at the end.

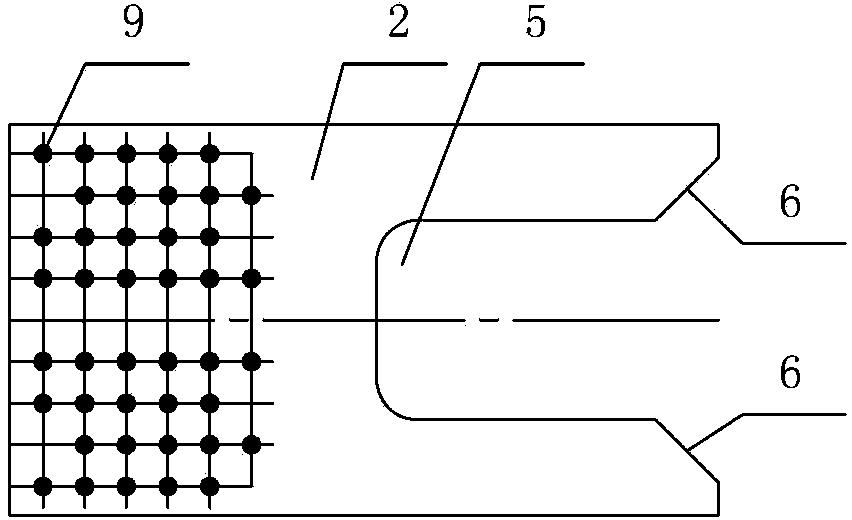

[0016] refer to figure 2 , There is a U-shaped groove 2 5 in the middle of the splicing joint plate 2 2 tail, the tail has a chamfer 6, and the end has a high-strength bolt hole.

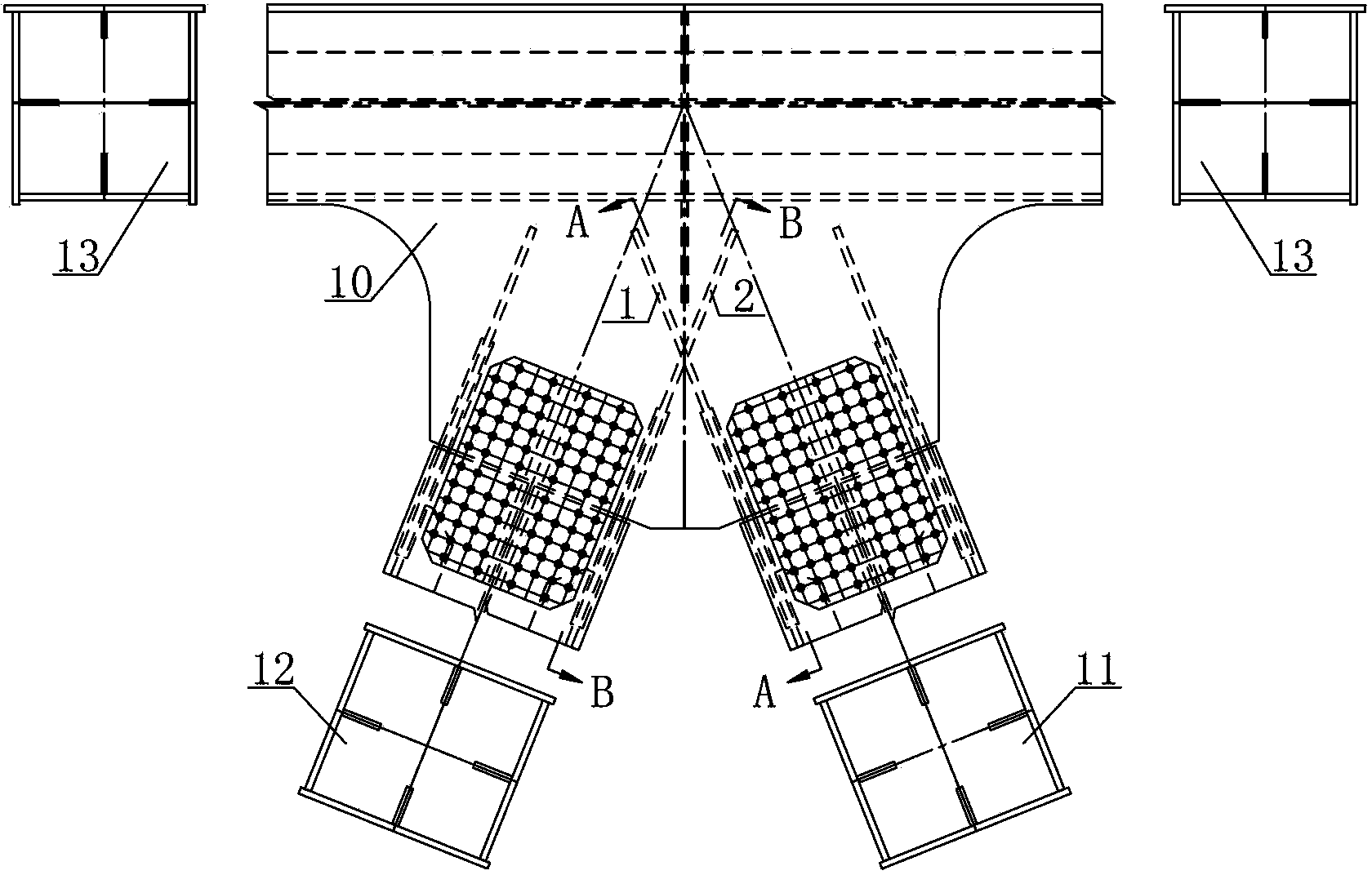

[0017] refer to figure 2 , 3 , 4, 5, the middle section of the U-shaped groove-3 notch of joint plate 1 passes through the U-shaped groove 2 of joint plate 2, and the space of the two spliced joint plates intersects and staggers each other. The two ends of the plate are welded to the gusset plate 10 at the node of the steel truss girder, and there is a weld 7 at the weld. The gusset plate 10 is welded to the chord 13 .

[0018] The joint plate 1 is bolted to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com