Protection method for reducing alternating current motor insulation bearing burning

A technology of AC motors and insulated bearings, which is applied in the direction of casings/covers/supports, electrical components, electromechanical devices, etc., and can solve problems such as bearing burnout failures, so as to ensure the safety of motors and equipment, reduce failure rates, and reduce insulation The effect of the bearing being burned by the shaft voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

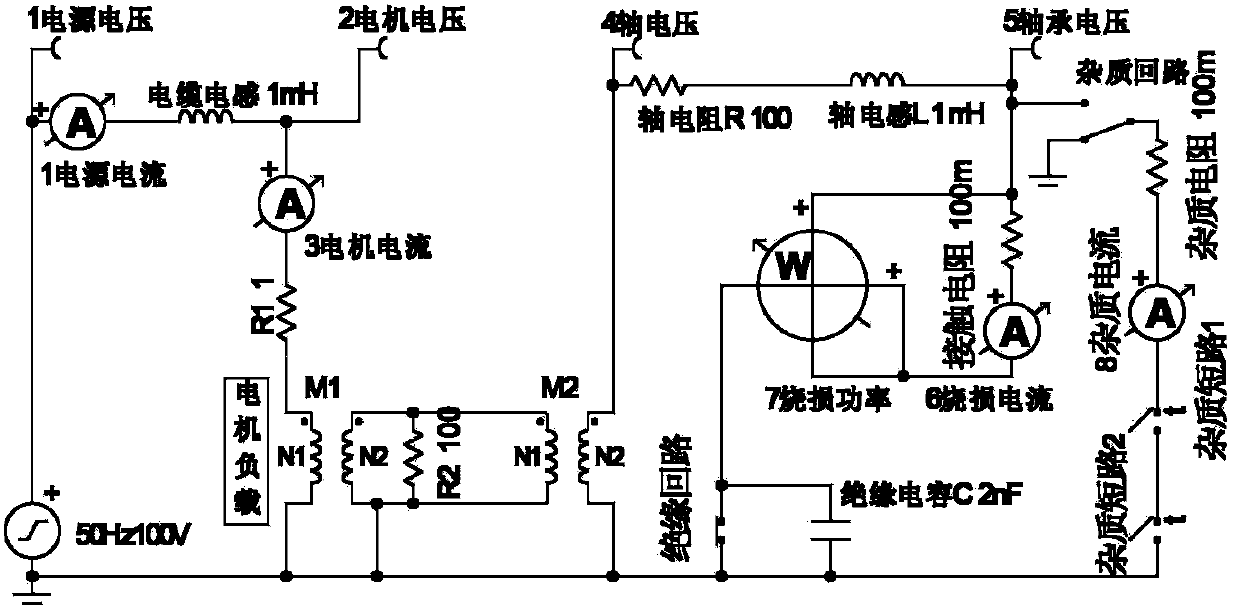

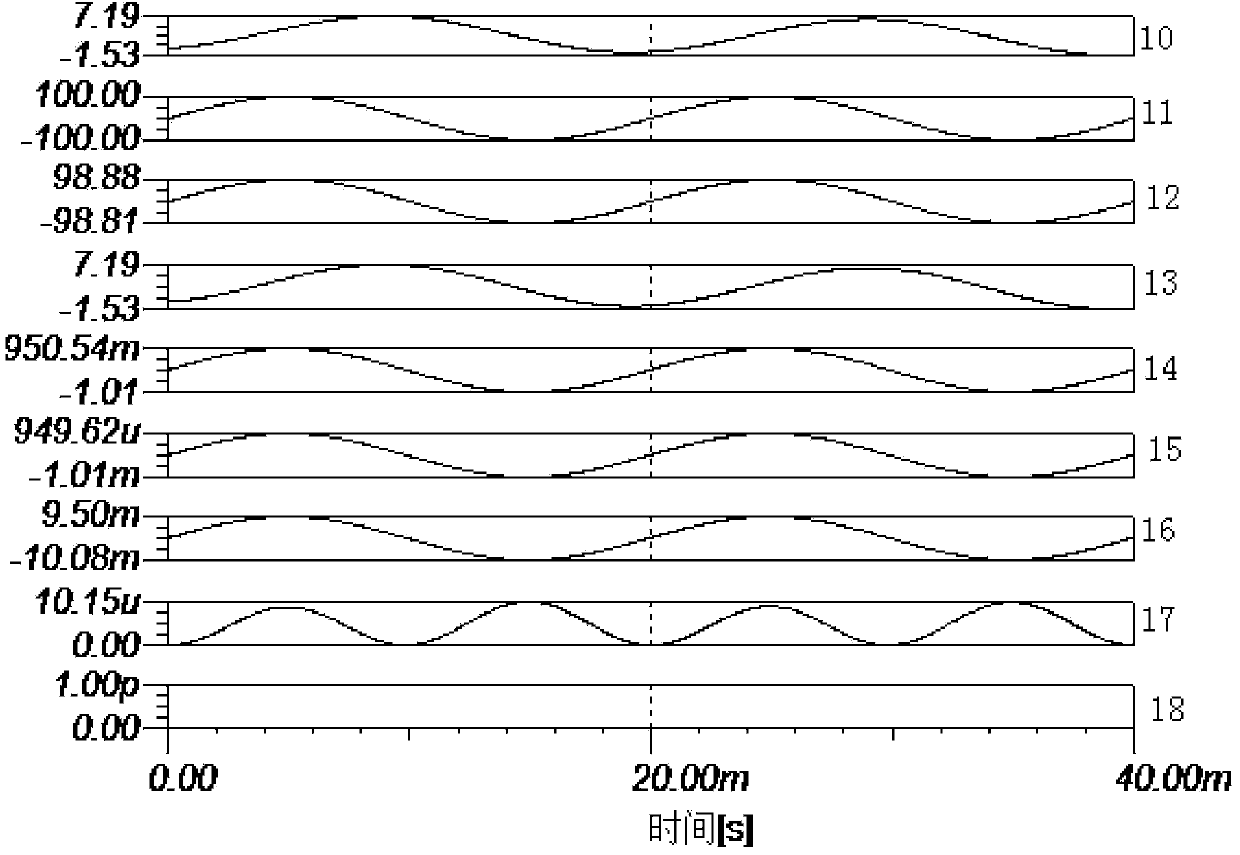

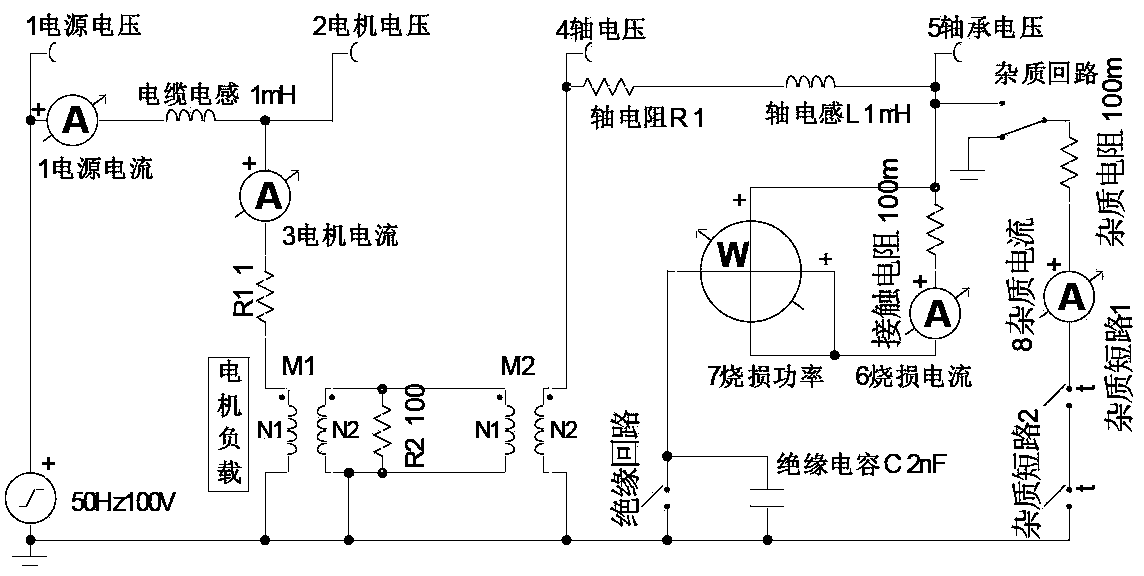

[0028] The theoretical basis of the above design is analyzed below.

[0029] The mechanism of insulating bearings to prevent shaft voltage and the shaft current formed from damaging the bearings is that the normal shaft voltage frequency is very low, and the capacitance between the inside of the insulating bearing and the bearing seat is only about 2000-3000pF, and its capacity for low-frequency shaft voltage The resistance is too large to cause a sufficiently large axial current. The voltage drop and power of the small axial current on the contact point resistance of the rolling element and the inner and outer rings are small, which is not enough to cause overheating damage to the contact point.

[0030] The process mechanism analysis of "roller burning caused by impurity short-circuit shaft voltage" is proposed as follows: With the long-term operation of the bearing, its cage or rolling working surface will inevitably wear and produce metal impurities, especially in the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com