A multi-light-emitting LED lamp with a lamp cup structure

A technology of LED lamps and LED strips, applied in the field of lighting, can solve the problems of light waste on the side of LED lamps, low light transmittance, large light loss of LED chips, etc., so as to improve light loss, improve light emission, and reduce light The effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

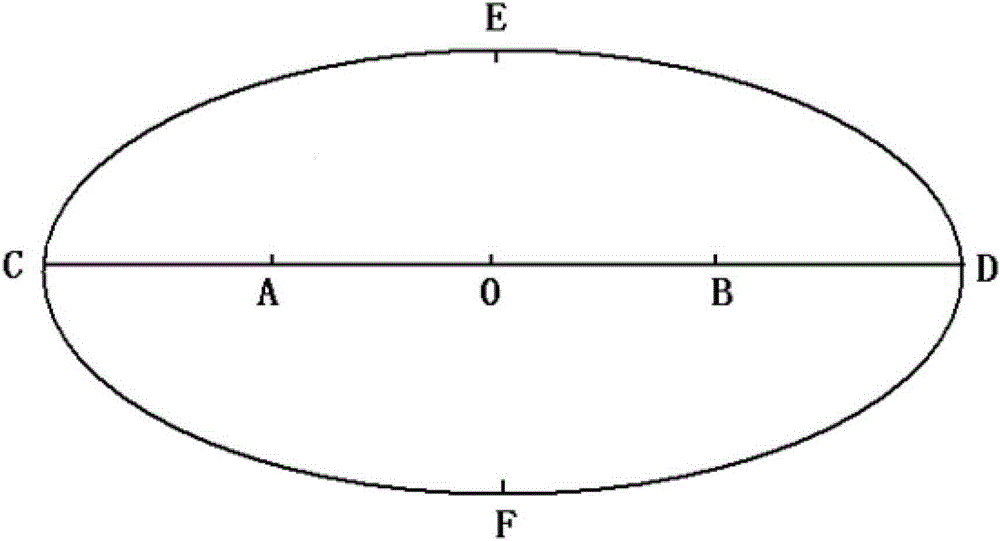

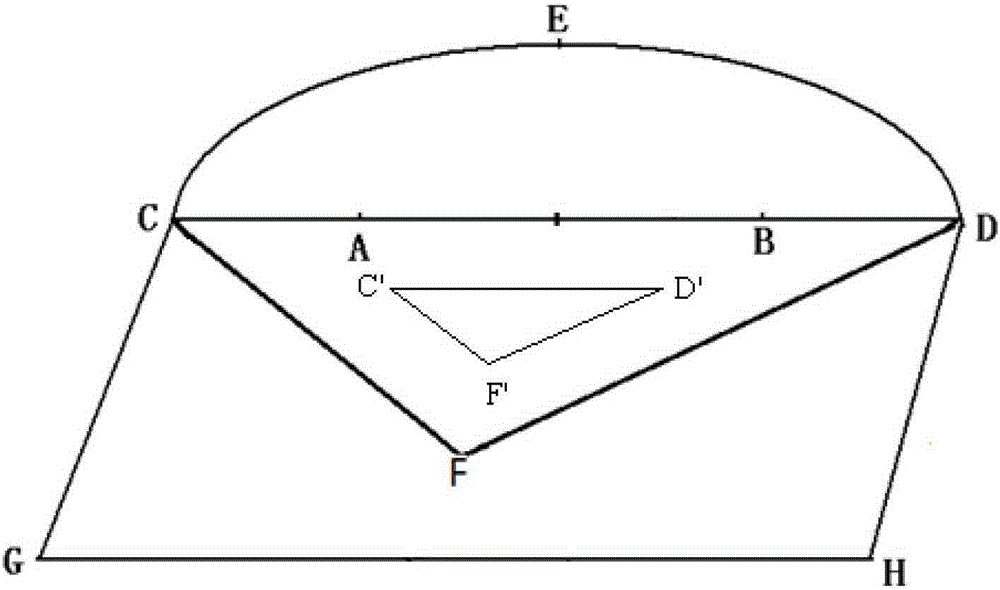

[0030] Such as figure 2 , 3 shown, in order to solve figure 1 Problems arising in the prior art, the present application provides a multi-luminous LED lamp with a lamp cup structure, including: a substrate with an integrally formed lamp cup structure (structure composed of GCDH), at least two groups of LED lamps Belt, a reflective element for increasing light reflection efficiency, wherein, the lamp cup structure has a cup top opening (the position of GH) and a cup bottom substrate (position between points C and D), and a cross-section of the cup bottom substrate Have triangular or V-shaped protrusions.

[0031] According to the above, the specific design of the application is as follows:

[0032] The LED light strips are respectively installed on the two sides of the protrusion (the position of CF and the position of FD), thereby forming two light-emitting surfaces in the structure of the lamp cup (that is, the surface formed by point CF and the surface formed by point DF...

Embodiment 2

[0041] combine figure 2 , 3 , further comprising: a lampshade installed on the cup top opening and suspended above the LED light strip (installed at the position of GH), the distance between the cup top opening and the protrusion is greater than a threshold.

[0042] The distance between the cup top opening GH and point F is greater than a threshold. This distance can make the average light intensity irradiated on the lampshade weaker, so that the lampshade with higher light transmittance can be used without glare, and the transmittance of the lampshade The increase in light efficiency also effectively reduces the light loss of the LED chip light strip.

Embodiment 3

[0044] Such as figure 2 , the included angles formed between the cup walls of the lamp cup structure and the cup bottom substrate are greater than 90 degrees, and the area of the cup top opening is larger than the area of the cup bottom.

[0045] or,

[0046] Such as image 3 As shown, the angle formed by one side of the lamp cup structure and the cup bottom substrate is greater than 90 degrees, and the angle formed by the opposite cup wall of the one side cup wall and the cup bottom substrate is less than or equal to 90 degrees, the cup wall on one side and the cup wall on the opposite side are arranged asymmetrically in a batwing shape to form directional light output (that is, along the extension direction of CG and DH).

[0047] Through the above two preferred settings of the included angles formed between the cup walls of the lamp cup structure and the cup bottom substrate, it is possible to control the directional light output of the lamp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com