The Method of Using Magnetic Coupler to Eliminate the Pressure Difference of Pump Pipe in Water Injection System

A technology of magnetic coupler and water injection system, applied in pump control, non-variable-capacity pump, machine/engine, etc., can solve the problems of downtime, large maintenance of variable frequency speed regulation system, etc. efficiency, good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

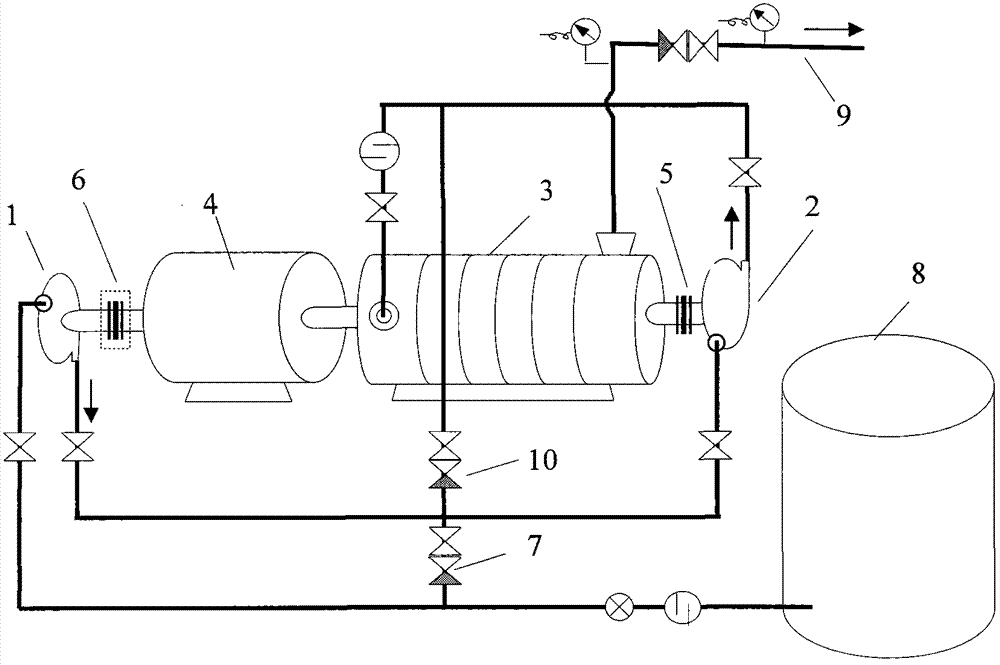

[0017] Such as figure 1 As shown, the front pump 1, the main pump (also known as the water injection pump) 3, and the follower front pump 2 operate in series, all of which are centrifugal pumps, and the water outlet of the main pump 3 supplies water to the water distribution pipeline 9. The front pump 1, the main pump 3 and the servo front pump 2 are all driven by the main pump motor 4, wherein the front pump 1 is driven by the main pump motor 4 through the magnetic coupling 6, and the servo front pump 2 is driven by the main pump motor 4 is driven by a magnetic coupling 5. During the operation of the main pump, according to the pressure requirements of the water distribution pipeline, the speed of the front pump is adjusted through the magnetic coupling 6. The set pump is disconnected from the running main pump or restored to the series operation relationship. The main pump 2 is a multi-stage pump (generally no less than 10 stages), the pre-stage pump 1 and the follow-up pr...

Embodiment 2

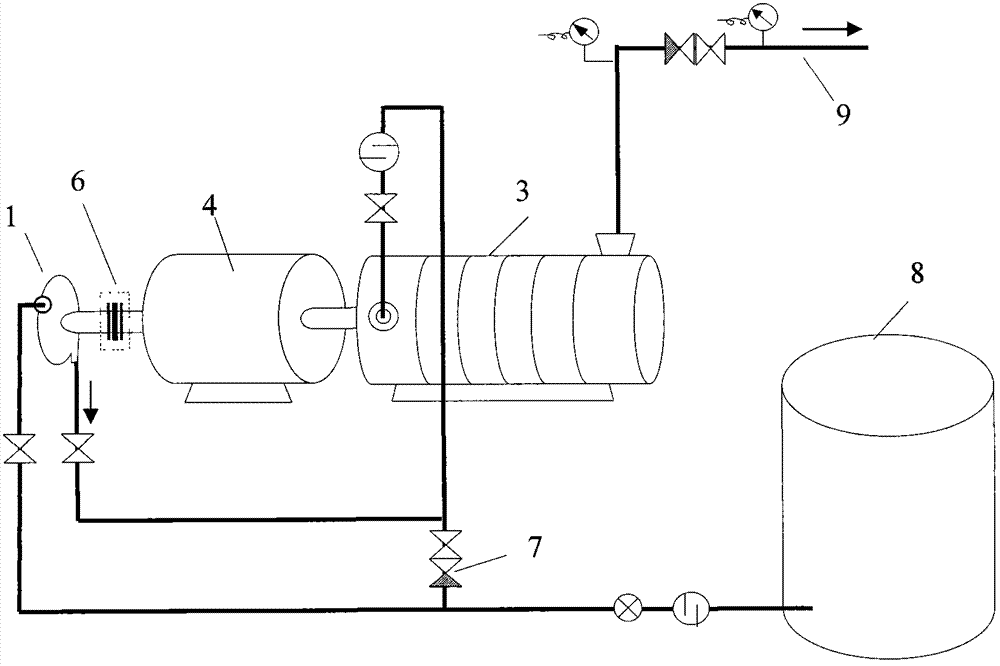

[0023] Such as figure 2 As shown, when the pressure required by the water distribution pipeline 9 has been changing within a small range, no follow-up front pump is provided, and only the front pump 1 and the main pump 3 are used to form a series operation process, that is, the front The pump 1 sucks the water from the water supply tank 8, feeds water to the inlet of the main pump 3, and finally outputs it to the water distribution pipeline 9 from the outlet of the main pump 3. The main pump 3 runs at the rated speed, and the speed of the front pump 1 is adjusted by the magnetic coupling 6 to realize the adjustment of the output pressure of the main pump 3 so as to match the pressure required by the water distribution pipeline 9 .

[0024] According to the pressure requirements of the water distribution pipeline, the front pump can be started and stopped at any time during the operation of the main pump. When the clutch function of the magnetic coupler 6 is used to start the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com