Method for recovering elementary substance arsenic from arsenic sulfide slag

A technology of arsenic sulfide and recycling bills, applied in the direction of improving process efficiency, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

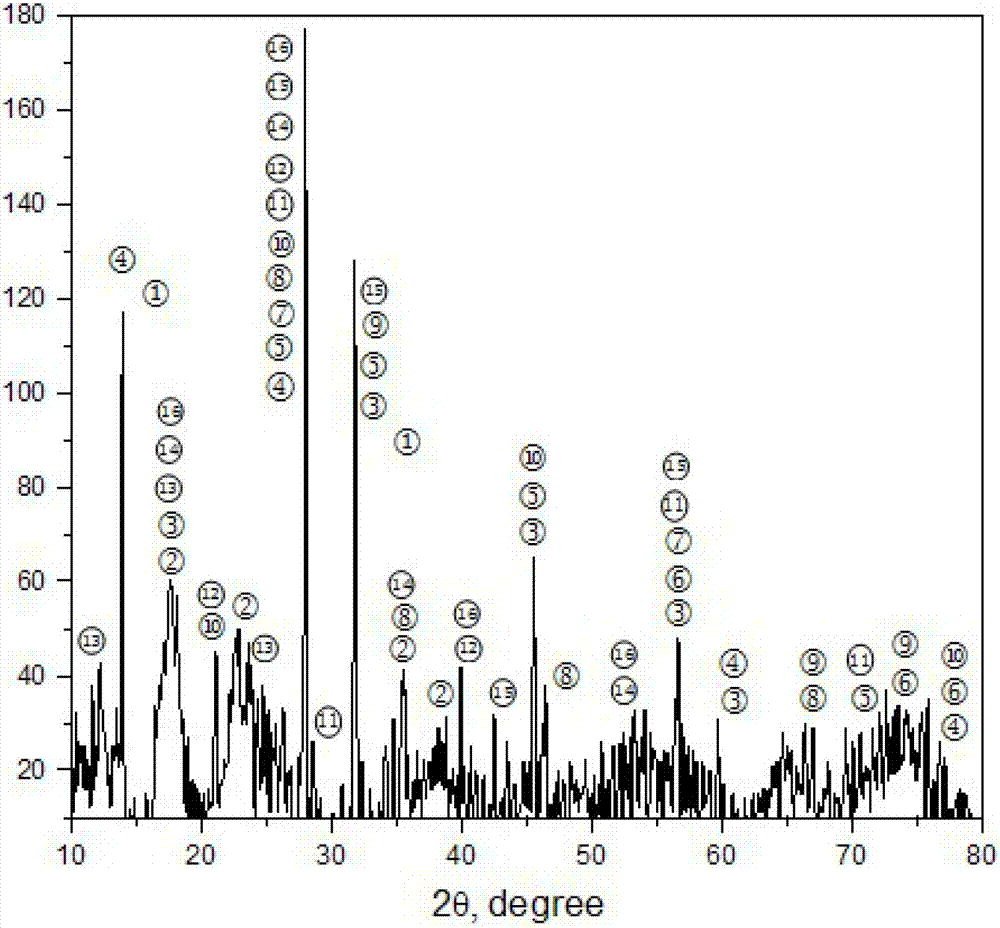

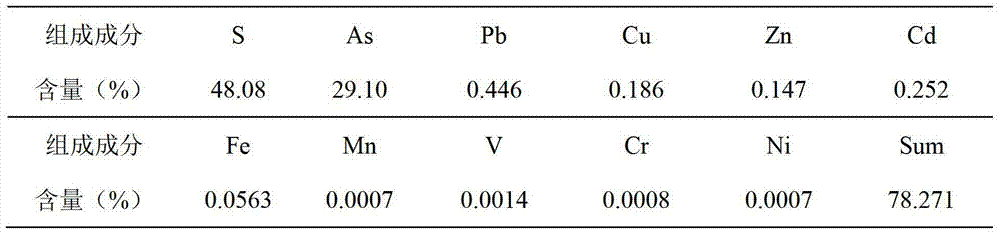

Image

Examples

Embodiment 1

[0031] A method for recovering elemental arsenic from arsenic sulfide slag, comprising a two-stage process "oxidative desulfurization leaching-acidification reduction", the specific steps are as follows:

[0032] (1) Take 5g of arsenic sulfide slag in a 250mL Erlenmeyer flask, add 100mL of distilled water, place the Erlenmeyer flask in a water bath and heat it to 75°C and keep it constant; add sodium hydroxide powder under stirring until the pH of the solution is 8-9; Then add 35mL of 30% hydrogen peroxide dropwise at a constant speed, and finish dripping in 40 minutes. After the dropping, rinse the bottle wall with a small amount of distilled water so that the liquid volume does not exceed 150mL. Continue to stir and react for 6 hours. The elemental sulfur generated during the reaction will have a large amount of conjunctiva. , rinsed repeatedly with distilled water, and the liquid volume was about 200mL after the reaction;

[0033] (2) After the reaction is completed, filter...

Embodiment 2

[0036] A method for recovering elemental arsenic from arsenic sulfide slag, comprising a two-stage process "oxidative desulfurization leaching-acidification reduction", the specific steps are as follows:

[0037](1) Take 10g of arsenic sulfide slag in a 500mL Erlenmeyer flask, add 200mL of distilled water, place the Erlenmeyer flask in a water bath and heat it to 75°C and keep it constant; add sodium hydroxide powder under stirring until the solution pH=8~9; Then add 70mL of 30% hydrogen peroxide dropwise at a constant speed, and finish dripping in 40 minutes. After the dropping, rinse the bottle wall with a small amount of distilled water so that the liquid volume does not exceed 300mL, and continue to stir for 6 hours. The elemental sulfur generated during the reaction will have a large amount of conjunctiva. , rinsed repeatedly with distilled water, and the liquid volume was about 400mL after the reaction;

[0038] (2) After the reaction is completed, filter with medium-spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com