Rotational flow dehydration and medium removing machine

A technology of cyclone dehydration and de-intermediation machine, which is applied in cyclone devices, devices whose axial directions of cyclone can be reversed, solid separation, etc. Difficulty and maintenance time, increase maintenance costs and other issues, to achieve the effect of saving required space, sufficient pulp separation, and increasing liquid flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention provides a cyclone dehydration and deintermediation machine, and the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

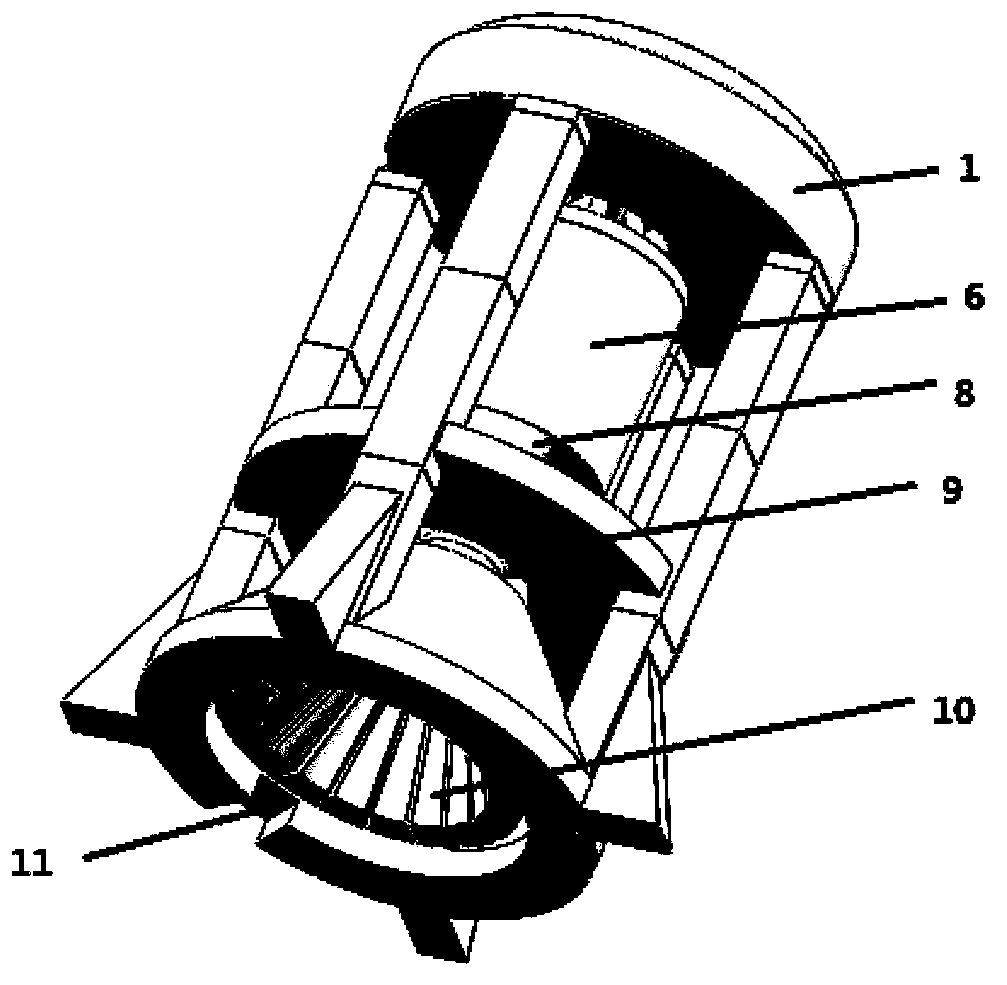

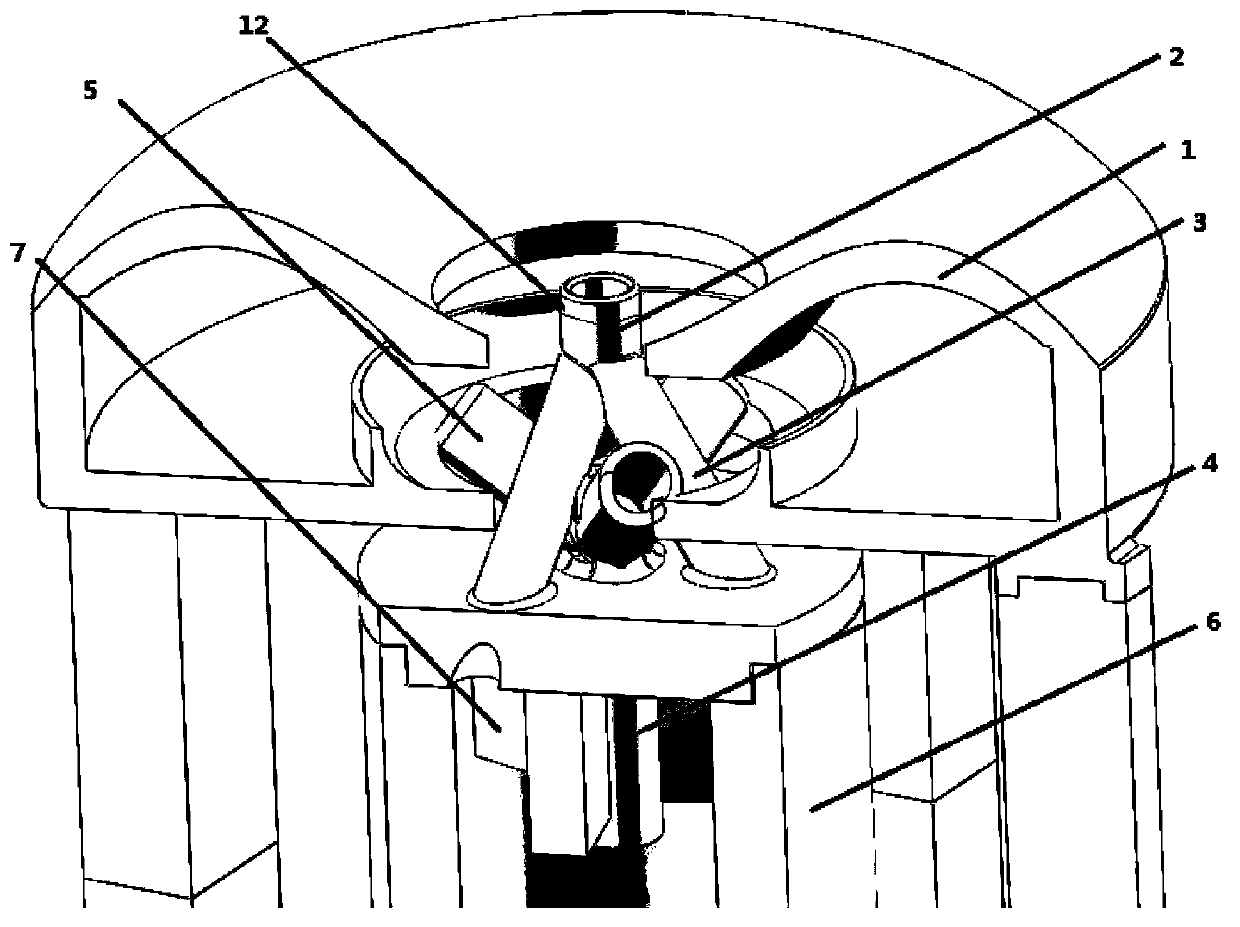

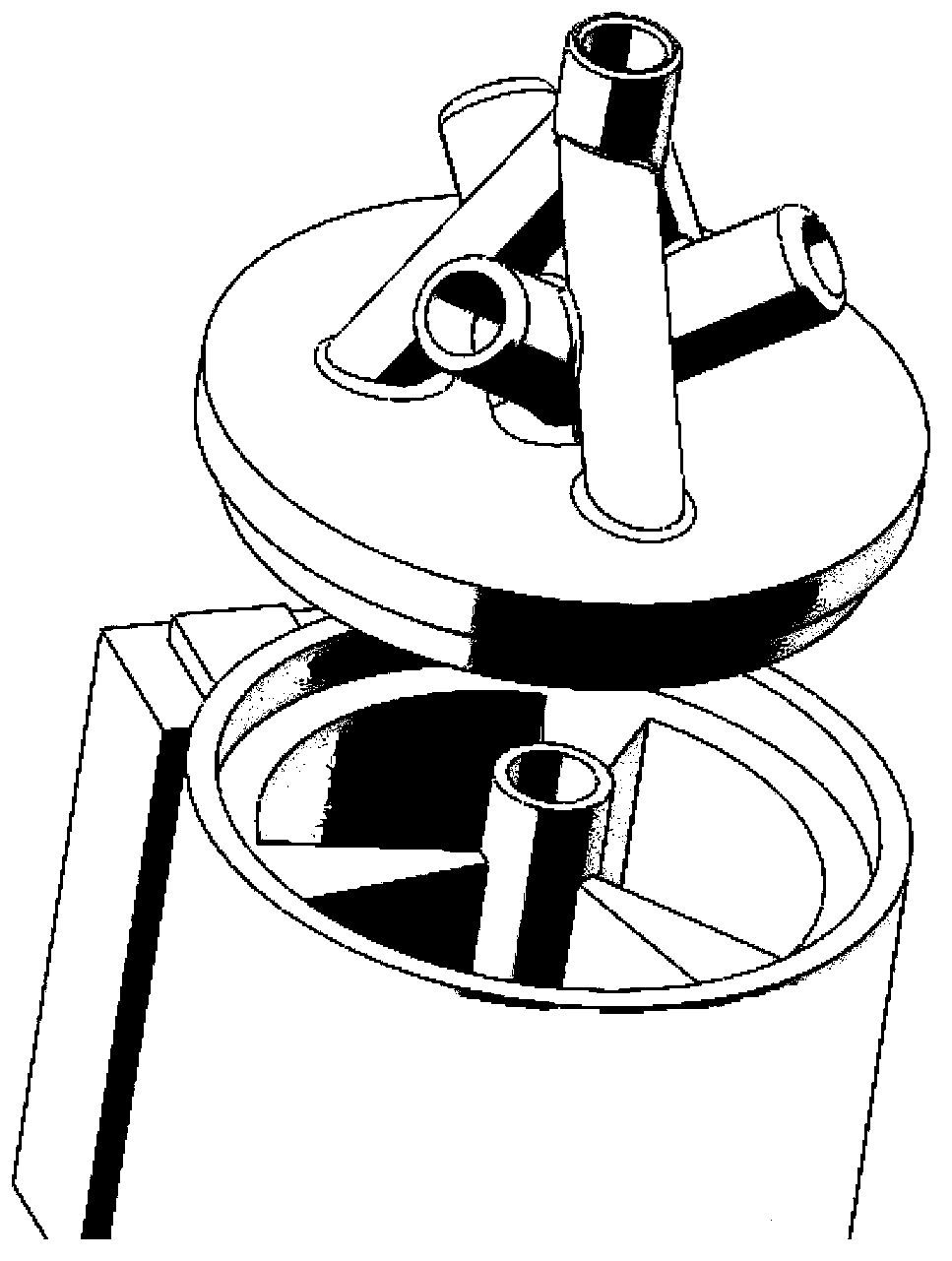

[0033] The structure of the present invention is as figure 1 As shown, the entire cyclone dehydration and deintermediation machine is fixed by the frame. The lower end of the cyclone cylinder 6 is connected to the cyclone cone 8 to form a cyclone together, and an overflow weir 1 is arranged above the cyclone cylinder 6 . The main body of the cyclone dehydration and deintermediation machine is composed of a cyclone rotated by the cylinder and a horn-shaped screen body 10 mechanically connected to it. The upper part can play the role of sorting the cyclone; the lower part can play the role of The role of dehydration and sieve. The barrel of the entire cyclone rotates together with the feed pipe.

[0034] The slurry in the cyclone part is fed by a centrifugal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com