Plate lock

A blade lock and blade technology, which is used in construction locks, cylinder pin locks, locks with turning keys, etc., can solve the problem of high mutual opening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

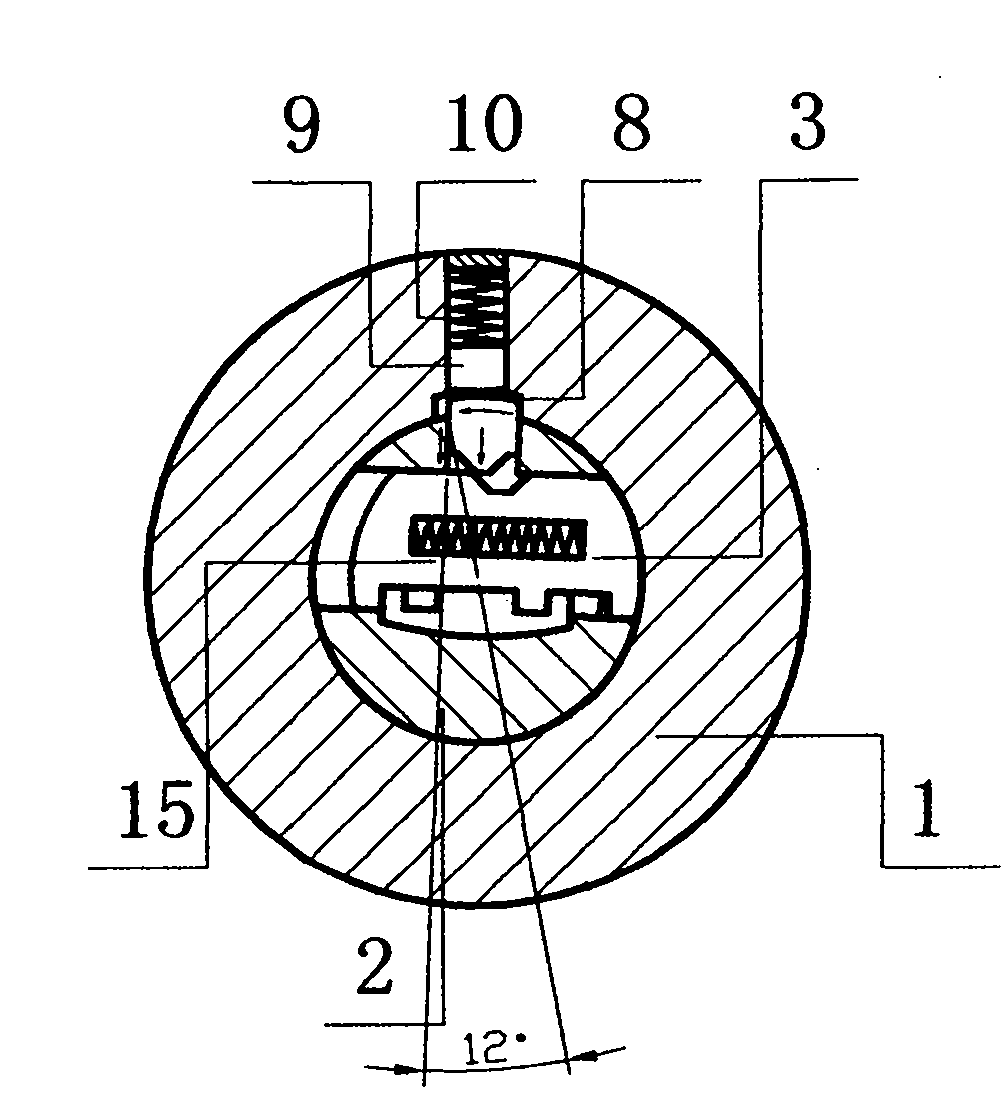

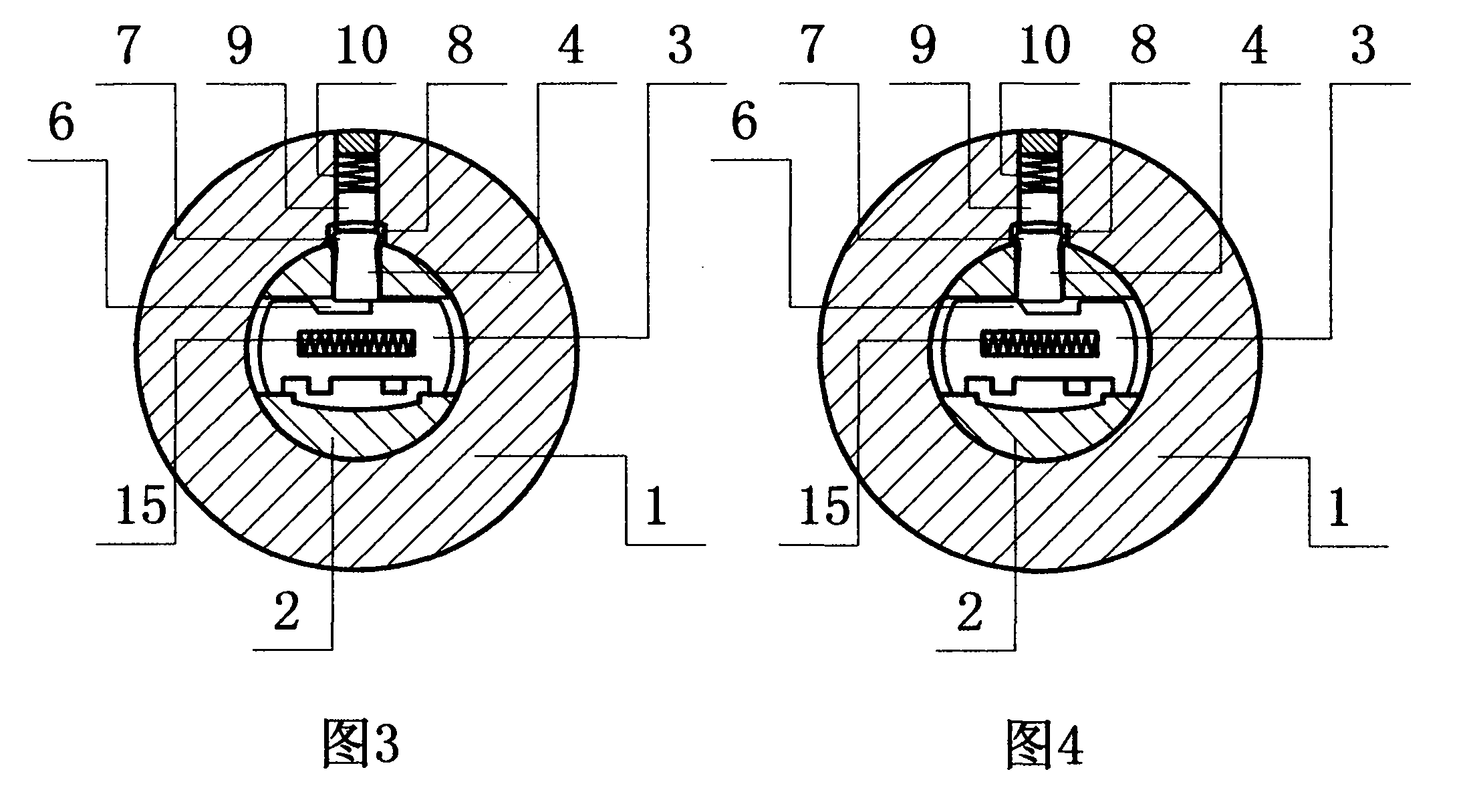

[0021] Figure 5 , Figure 6 Shown is the first embodiment of the present invention, including lock body 1, lock core 2, leaf 3, Shaped locking pin 4, the lock core 2 is sleeved in the lock body 1, and the lock core 2 is provided with several groups of leaf sheets 3 stacked in front and back as a group, and the middle part of the leaf sheet 3 is provided with a return spring 15. There are 3 pieces One side of the groove 6 pushed by the spring 15 is set as a vertical side, and the side pushed by the key tooth flower is set as a hypotenuse; the lock core 2 corresponds to the leaf 3 Shaped groove 6 places are provided with Form locking pin 4, Two sides 7 of the outer end of shape locking pin 4, the included angle with the center of circle of lock core respectively is 0 °, and corresponding to lock body 1 There is a locking groove 8 at the shape locking pin, and a flat ball 9 and a return spring 10 are provided.

[0022] When opening, when the matching key is inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com