Method for discriminating neutral gear on basis of electronic neutral gear sensor

A technology of a neutral gear sensor and a discrimination method, which is applied to components with teeth, transmission device control, belts/chains/gears, etc., which can solve problems such as sensor error installation, error, and inaccurate neutral gear judgment, and achieve low cost and development The effect of short time, improved accuracy and real-time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

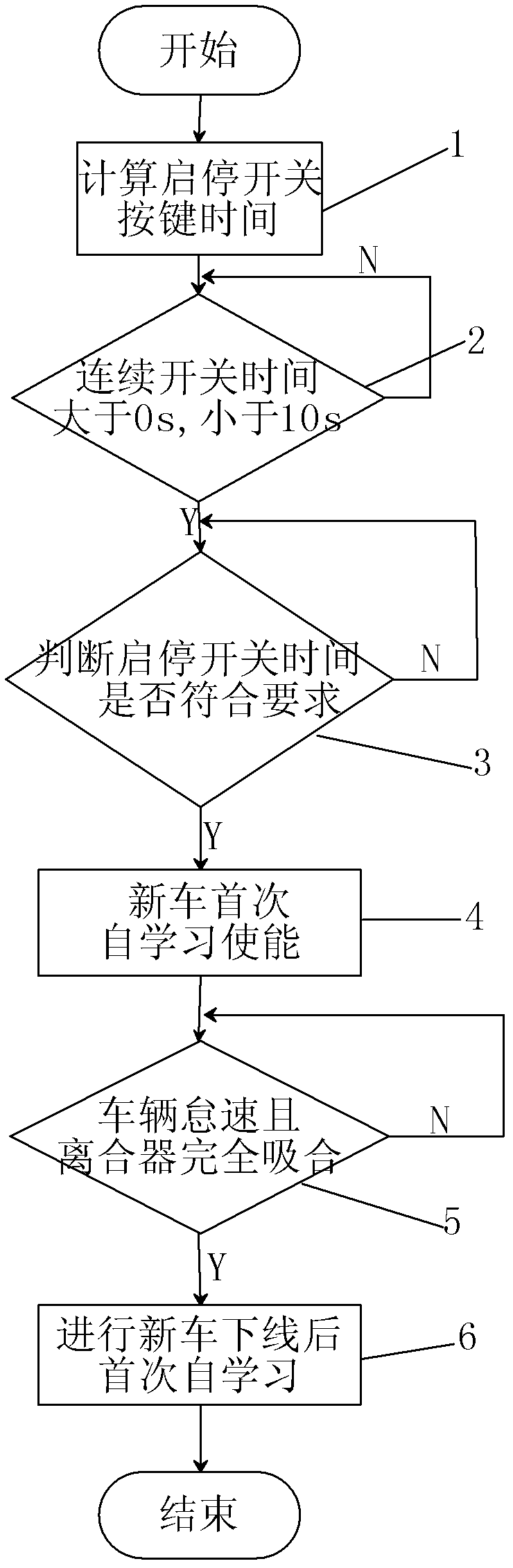

[0030] In this embodiment, on the basis of the electromagnetic neutral gear sensor, a neutral gear self-learning method is designed on the software level without any other structural modifications to improve the accuracy of neutral gear judgment and adapt to different working conditions and conditions. vehicle type. The neutral gear self-learning method proposed in this embodiment is divided into two stages, and there is no necessary connection between them.

[0031] The first stage: the first self-study after the new car rolls off the assembly line

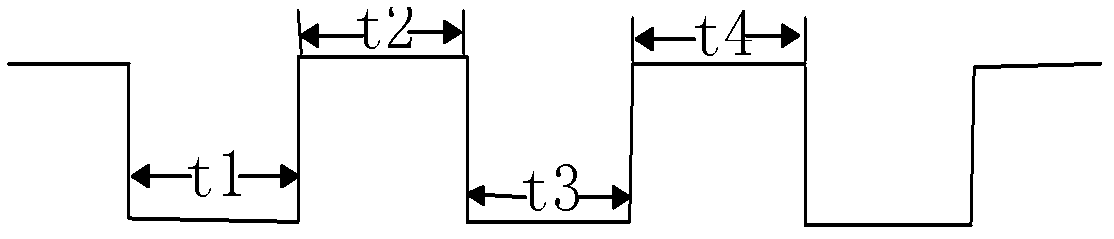

[0032] The first self-study after the new car comes off the assembly line is triggered by the start-stop switch signal. The start-stop switch is installed on the lower left of the car dashboard and is a button switch. When pressed, the start-stop function is turned on, and when pressed again, the start-stop function is turned off.

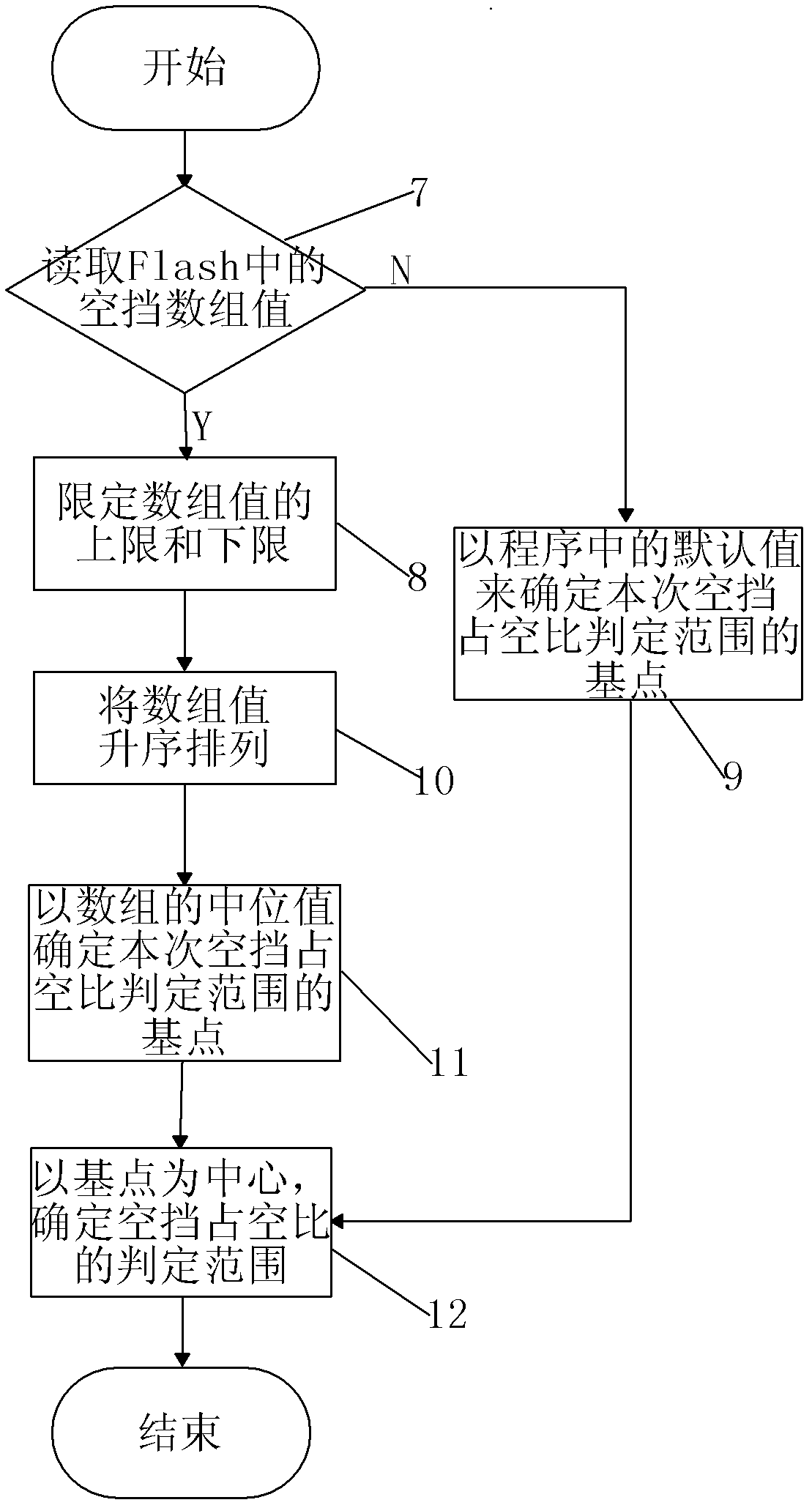

[0033] The program first defines a neutral array with a size of 30 (of course, arrays of other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com