Digital inkjet printer with transparent ink

A technology of transparent ink and inkjet printer, which is applied in printing and other directions, can solve the problems of digital inkjet printer’s printing capacity bottleneck and digital inkjet printer’s inability to print transparent colors, so as to increase practicability and product competitiveness, improve service life and Performance effect, enhance the effect of application level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

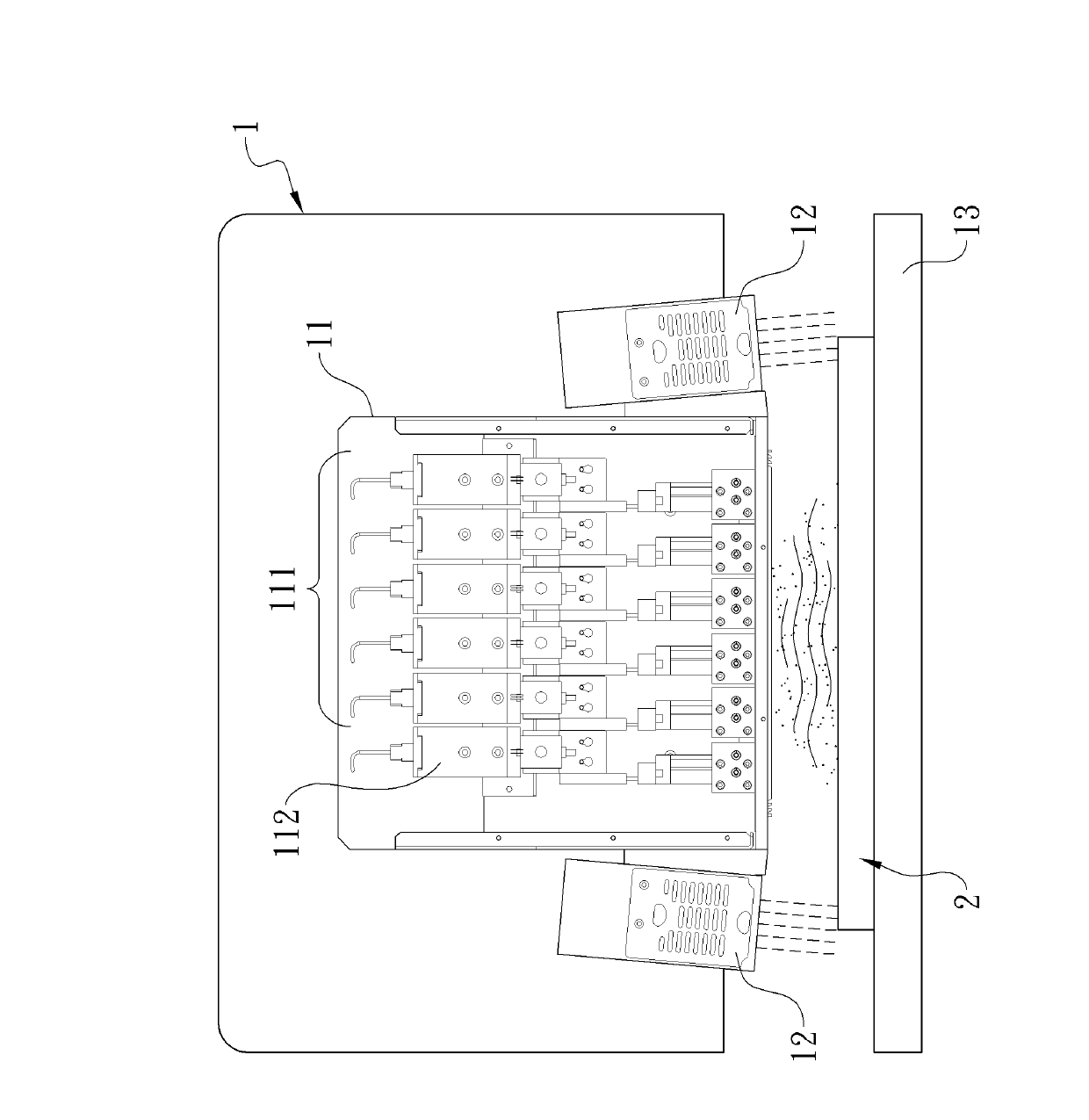

[0016] see figure 1 , which is an embodiment of the digital inkjet printer 1 with transparent ink in the present invention, comprising an inkjet module 11, a UV light projection device 12 respectively arranged on the left and right sides of the inkjet module 11 and a working platform with a heating function 13, wherein the working platform 13 is used to accept the workpiece 2 to be printed, and during or after the inkjet module 11 sprays ink onto the workpiece 2 on the working platform 13, the workpiece 2 is heated to harden the processing Ink droplet on piece 2.

[0017] The inkjet module 11 has a plurality of colored ink cartridges 111 and a transparent ink cartridge 112 arranged on the left side of the colored ink cartridges 111, wherein the colored ink cartridges 111 are respectively filled with solvent-based inks of different colors, such as blue, red, Solvent-based inks such as yellow, black, light blue, light red, orange and green, and the transparent ink cartridge 112...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com