Different-voltage-class subsection arc-extinguishing anti-thunder gap device

A technology of voltage level and arc extinguishing device, which is applied to overvoltage arresters, circuits, spark gaps, etc. that apply spark gaps, and can solve the problems of manual installation, high maintenance difficulty, increased replacement and maintenance workload, and easy re-ignition, etc. problems, to achieve the effect of reducing the workload and cost of manual maintenance, reducing the rate of lightning tripping and accidents, and reducing the number of towers going online

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

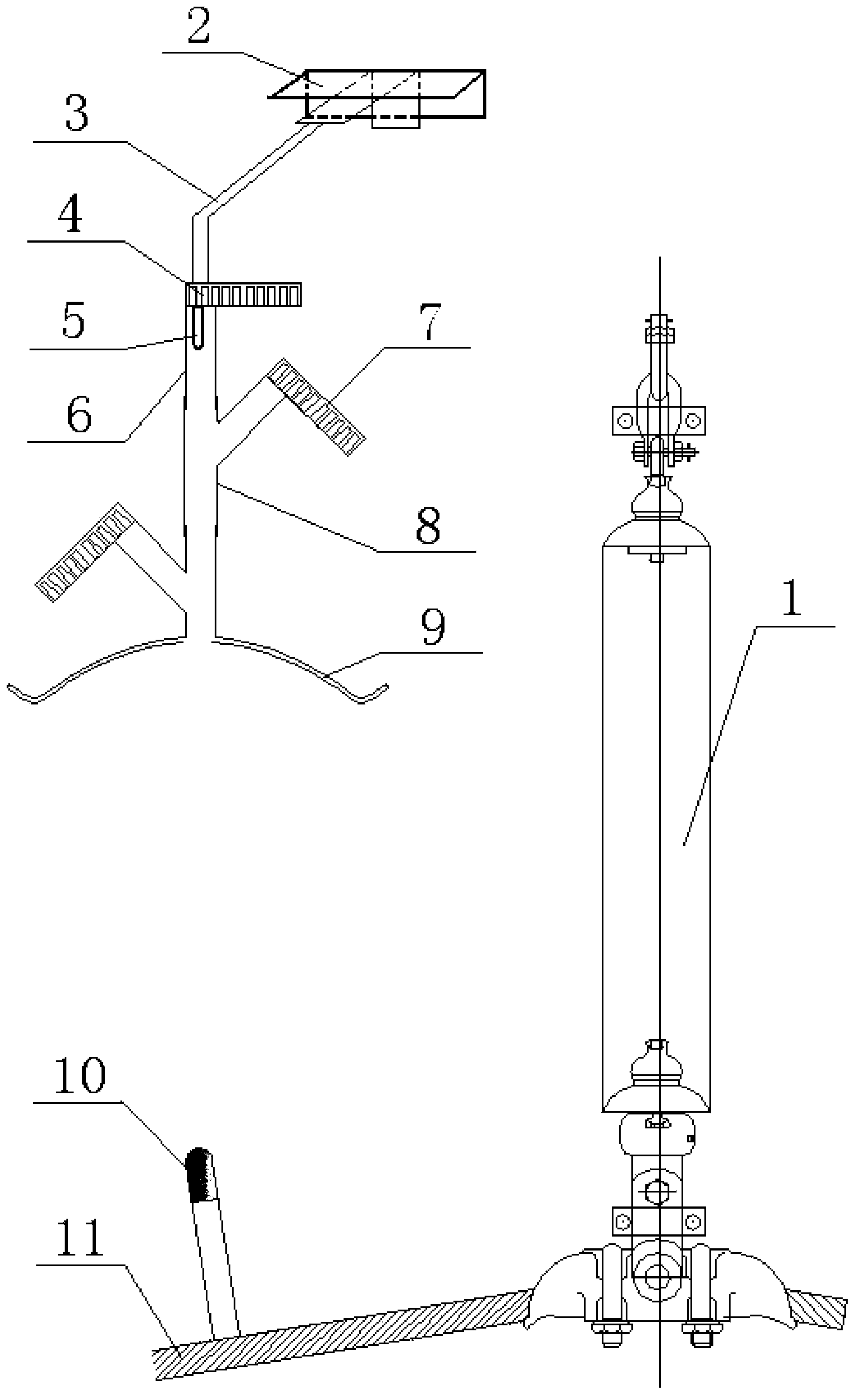

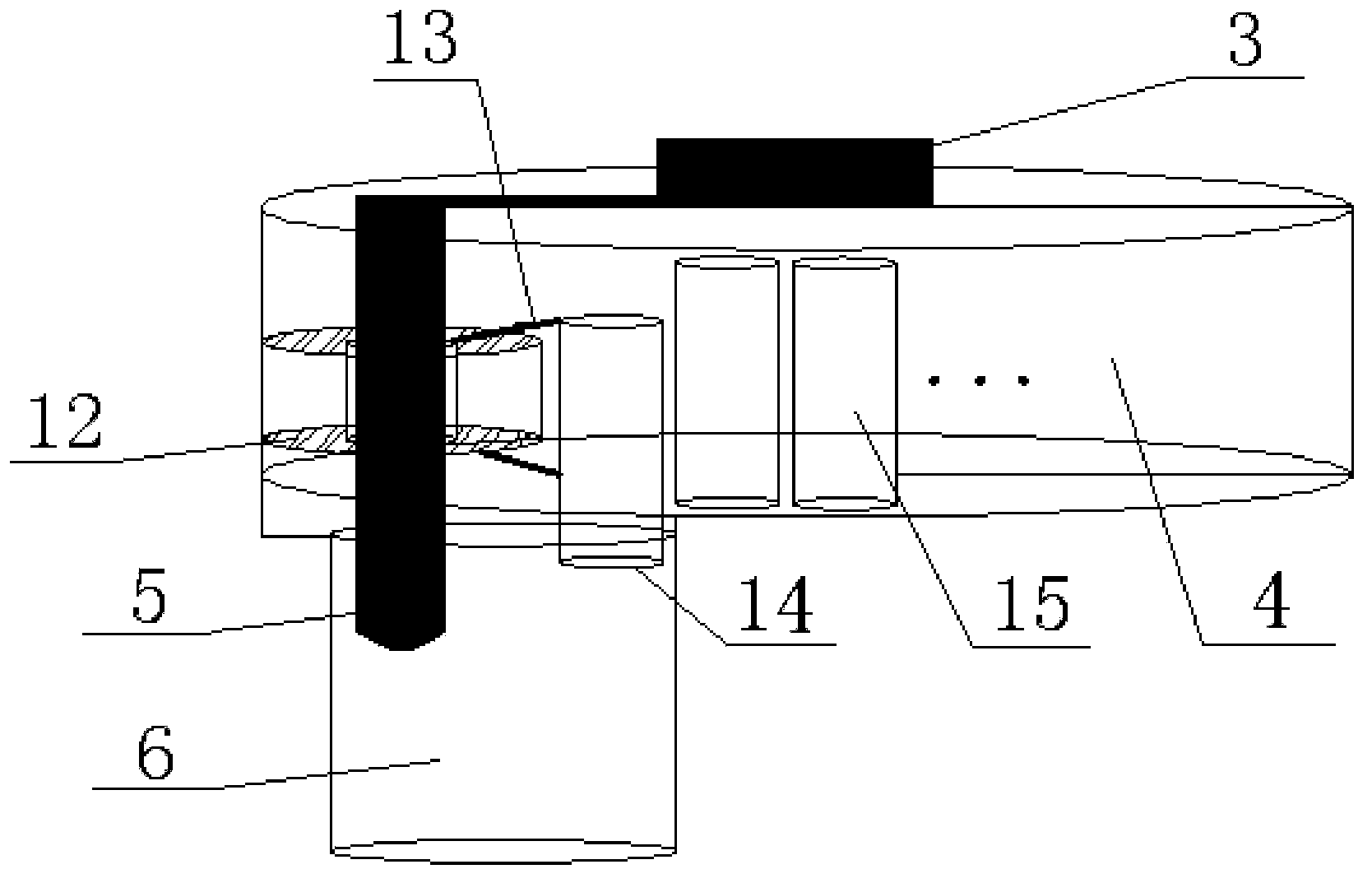

[0038] Such as figure 1 , image 3 , Figure 4 As shown, a segmented arc extinguishing lightning protection gap device of different voltage levels includes an arc extinguishing device and a protection gap device installed in parallel near the insulator string 1; the protection gap device is mainly composed of a low-voltage terminal electrode 5 and a high-voltage terminal electrode 10; The arc extinguishing device includes an arc extinguishing cylinder 6 and a disc-shaped arc extinguishing magazine I 4, and the arc extinguishing magazine I 4 is provided with a trigger coil 12, a trigger electrode 13, and a projectile trigger position 14, The arc extinguishing projectile 15 and the planar scroll spring 16; one end of the trigger electrode 13 is connected to the trigger coil 12, and the other end extends to the projectile trigger position 14 to be connected to the arc extinguishing projectile 15; the planar scroll spring 16 is installed At the center position of the arc extinguishi...

Embodiment 2

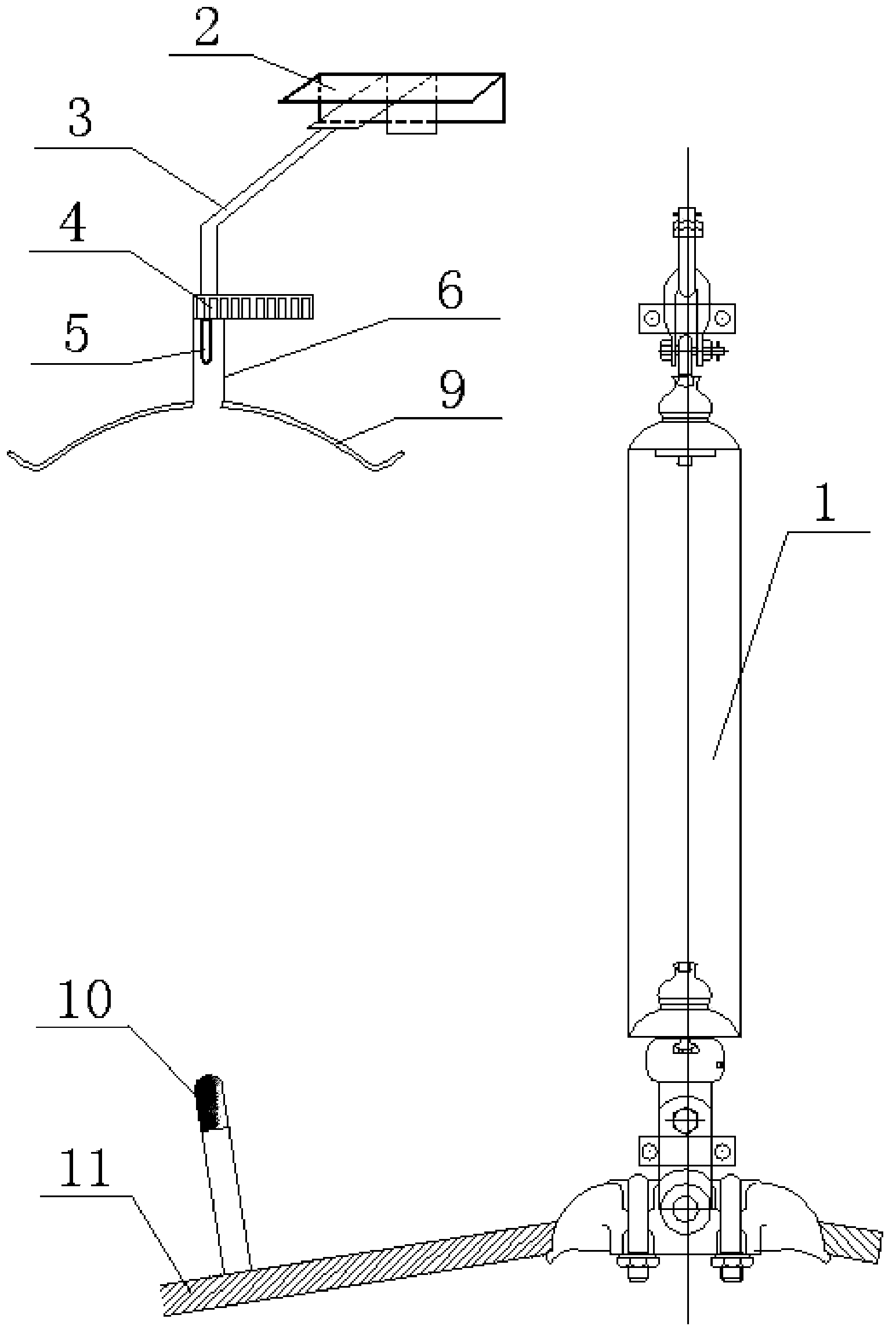

[0040] Such as figure 2 , image 3 , Figure 4 As shown, a segmented arc extinguishing lightning protection gap device of different voltage levels includes an arc extinguishing device and a protection gap device installed in parallel near the insulator string 1; the protection gap device is mainly composed of a low-voltage terminal electrode 5 and a high-voltage terminal electrode 10; The arc extinguishing device includes an arc extinguishing cylinder 6 and a disc-shaped arc extinguishing magazine I 4, and the arc extinguishing magazine I 4 is provided with a trigger coil 12, a trigger electrode 13, and a projectile trigger position 14, The arc extinguishing projectile 15 and the planar scroll spring 16; one end of the trigger electrode 13 is connected to the trigger coil 12, and the other end extends to the projectile trigger position 14 to be connected to the arc extinguishing projectile 15; the planar scroll spring 16 is installed At the center position of the arc extinguish...

Embodiment 3

[0042] A segmented arc extinguishing lightning protection gap device of different voltage levels, comprising an arc extinguishing device and a protection gap device installed in parallel near the insulator string 1; the protection gap device is mainly composed of a low-voltage terminal electrode 5 and a high-voltage terminal electrode 10; The arc extinguishing device includes an arc extinguishing cylinder 6 and a disc-shaped arc extinguishing magazine I 4. The arc extinguishing magazine I 4 is provided with a trigger coil 12, a trigger electrode 13, a projectile trigger position 14, and an arc extinguishing projectile. 15 and a flat spiral spring 16; one end of the trigger electrode 13 is connected to the trigger coil 12, and the other end extends to the projectile trigger position 14 is connected to the arc-extinguishing projectile 15; the flat spiral spring 16 is installed in the arc-extinguishing The central position of the storage compartment I 4; the arc-extinguishing proje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com