Method for dynamically grading major hazard sources of liquid chemicals in storage tank region of petrochemical wharf

A petrochemical and dynamic grading technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems that do not conform to actual production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

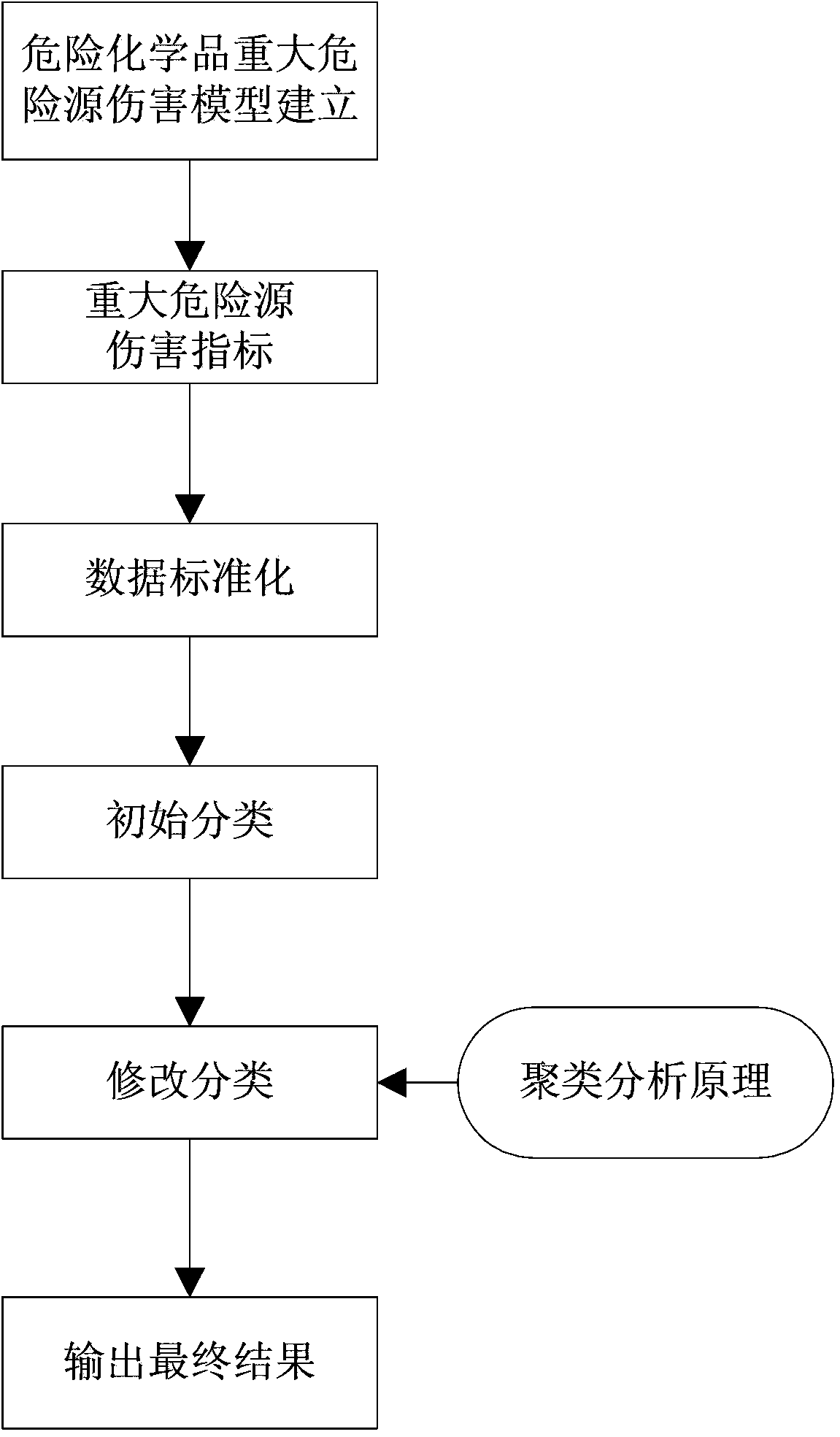

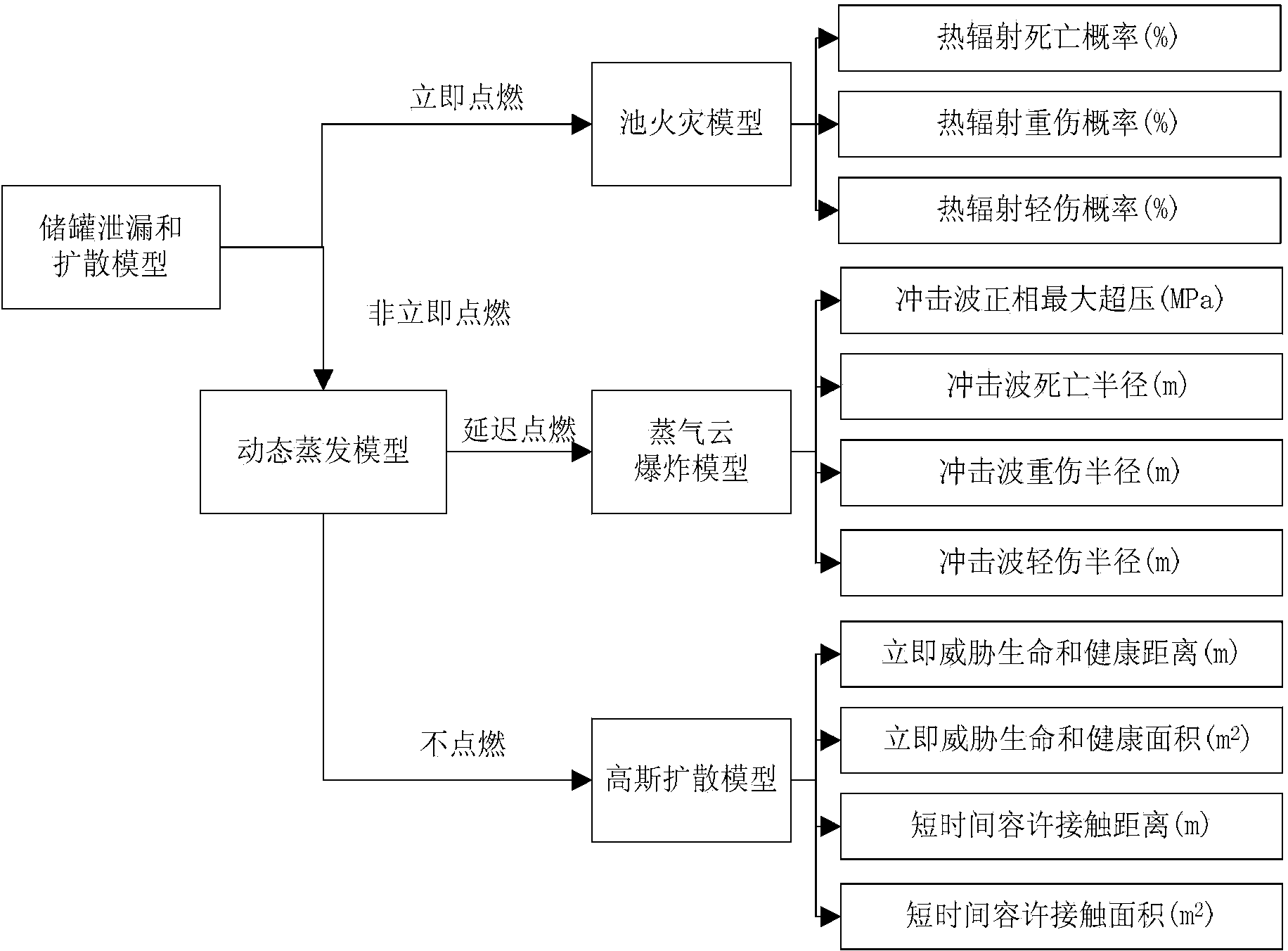

[0051] A method for dynamic classification of major hazard sources of liquid chemicals in the storage tank area of a petrochemical wharf according to the present invention will be further described below in conjunction with the accompanying drawings.

[0052] The design idea of the present invention is to apply the idea of dynamic classification to the classification of major hazard sources, and accurately reflect the relative risk relationship of various hazard sources when reserves change. The hierarchical calculation program of the present invention is realized on the LabVIEW virtual instrument platform. LabVIEW is an integrated program development environment based on "graphics". Built-in signal acquisition, measurement analysis and data display functions. It integrates development, debugging and operation. Different from other instrument platforms, LabVIEW adopts "graphical" language programming instead of textual language programming. LabVIEW is easy to program,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com