Pyriform shaft-end baffle

A shaft end, pear-shaped technology, applied in the direction of shafts, shafts and bearings, connecting components, etc., can solve the problems of fastening bolt shearing, shaft locking failure, etc., to meet the shear strength, improve the locking effect, and avoid being cut effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

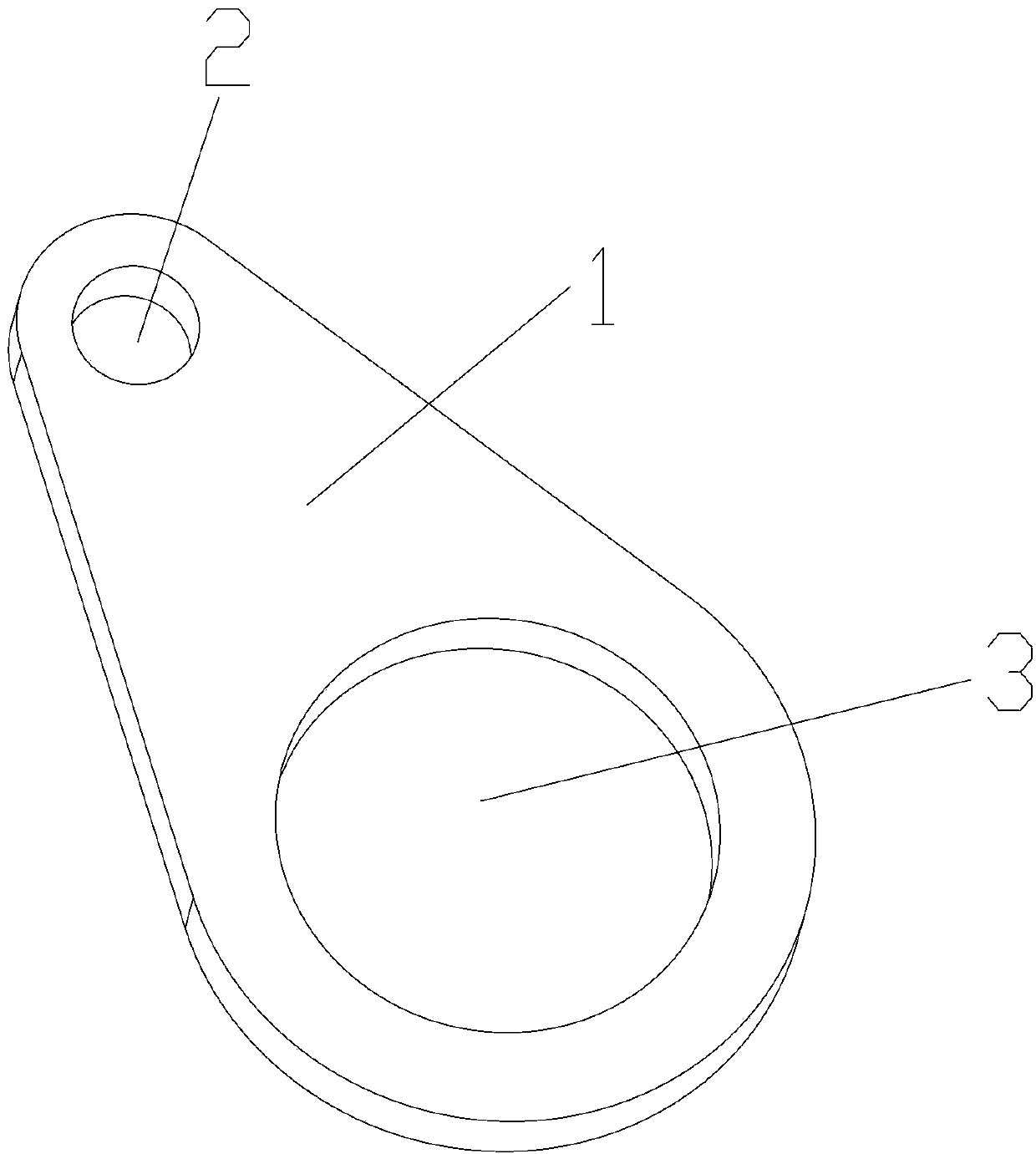

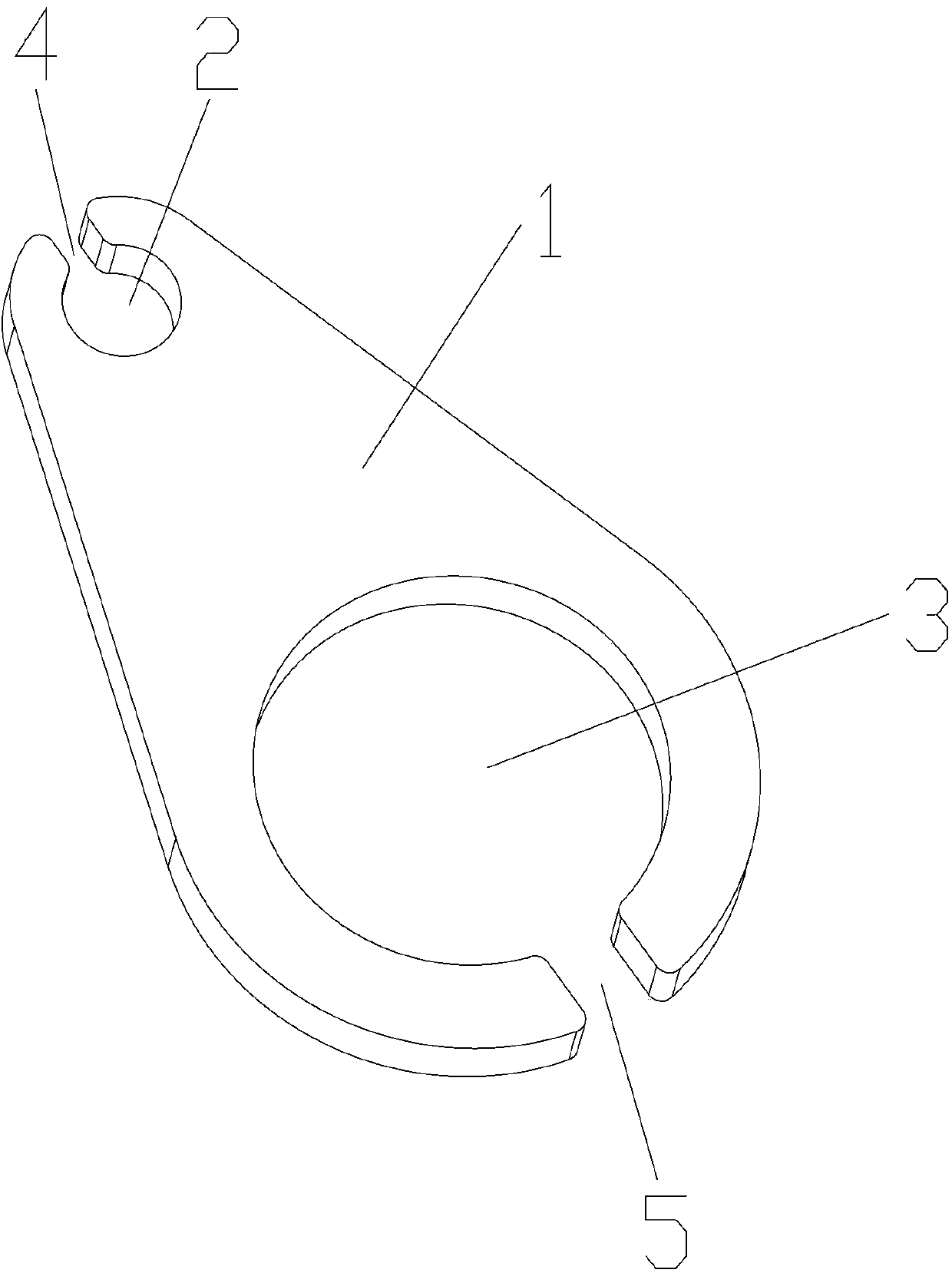

[0014] as attached figure 2 The shown pear-shaped shaft end baffle according to the present invention includes a baffle body 1, and a first hole 2 and a second hole 3 are opened on the baffle body 1, and the length direction of the baffle body 1 is The ends of the first hole 2 and the second hole 3 are respectively opened with a first groove 4 and a second groove 5 communicating with the outside; the width of the first groove 4 is smaller than the diameter of the first hole 2; The width of the groove 5 is less than the diameter of the second hole 3; the width of the second groove 5 is 1 / 5 of the diameter of the second hole 3; the width of the first groove 4 is 1 / 3 of the diameter of the first hole 2 one.

[0015] In the pear-shaped shaft end baffle of the present invention, since the ends of the baffle body in the length direction are respectively provided with a first groove and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com