Novel air filter bag

An air filtration and filter bag technology, applied in the directions of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as limiting the filtration performance of filter bags, and achieve the effect of enhancing ventilation strength and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

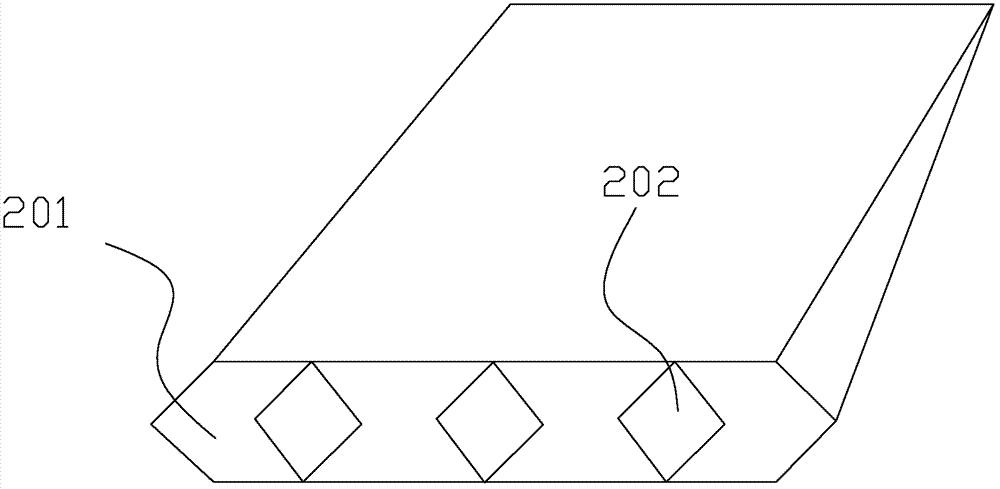

[0011] Such as figure 1 As shown, a novel air filter bag according to the present invention mainly includes two parts: a large filter bag 201 and a small filter bag 202. The small filter bag is located inside the large filter bag, and its filtering area is 50% of the large filter bag. Bonding by hot melt, filter pouches are also bonded by hot melt. The present invention does not need to replace the filter frame under the condition of small volume of the air-conditioning box and large air volume. Adding the filter pouch process in the conventional filter bag is equivalent to increasing the filter area by 50% in the original filter surface, and using The high-frequency technology hot-melts the bag sheets to enhance the ventilation strength of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com