Cast-in-place box beam lateral die sliding construction device and method

A construction device and side form technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as time-consuming and labor-intensive, complicated construction methods, and achieve economical, practical, and simple operation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

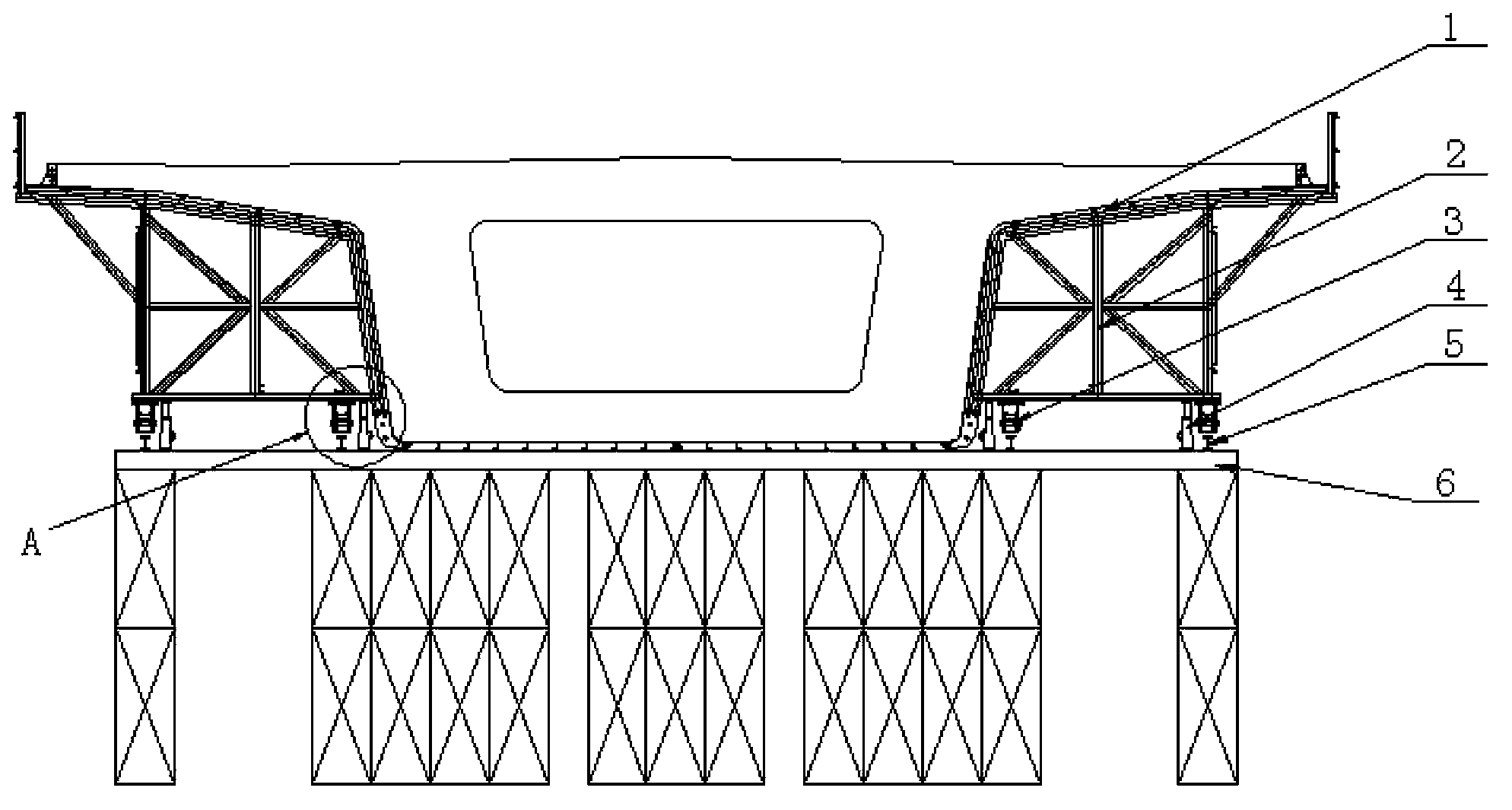

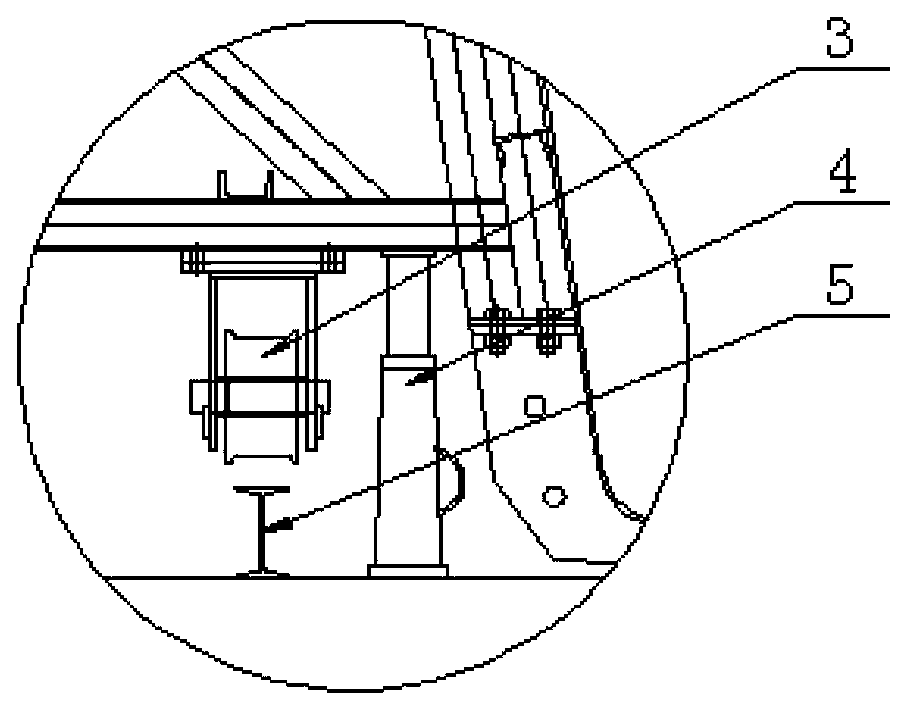

[0021] A cast-in-place box girder side form sliding construction device, which is composed of a movable side form, a sliding track 5 and a jack 4, and the movable side form is composed of a side form 1, a side form truss 2 and a fixed installation at the bottom of the side form truss Two rows of walking pulleys 3 are formed, and the side-by-side sliding rails are fixed on the support 6, and the movable side molds are movable and installed on the sliding rails, and jacks are symmetrically installed between the support top and the side mold bottoms. The jack position card is close to the position of the traveling pulley. The above-mentioned movable side forms and sliding tracks are the same structures locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com