Absorbent

A technology for absorbent products and absorbent layers, applied in the field of absorbent products, can solve problems such as slow flow of viscous liquids, clogged capillaries, easy to clog capillaries, etc., and achieve the effects of improving comfort, reducing reverse osmosis, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

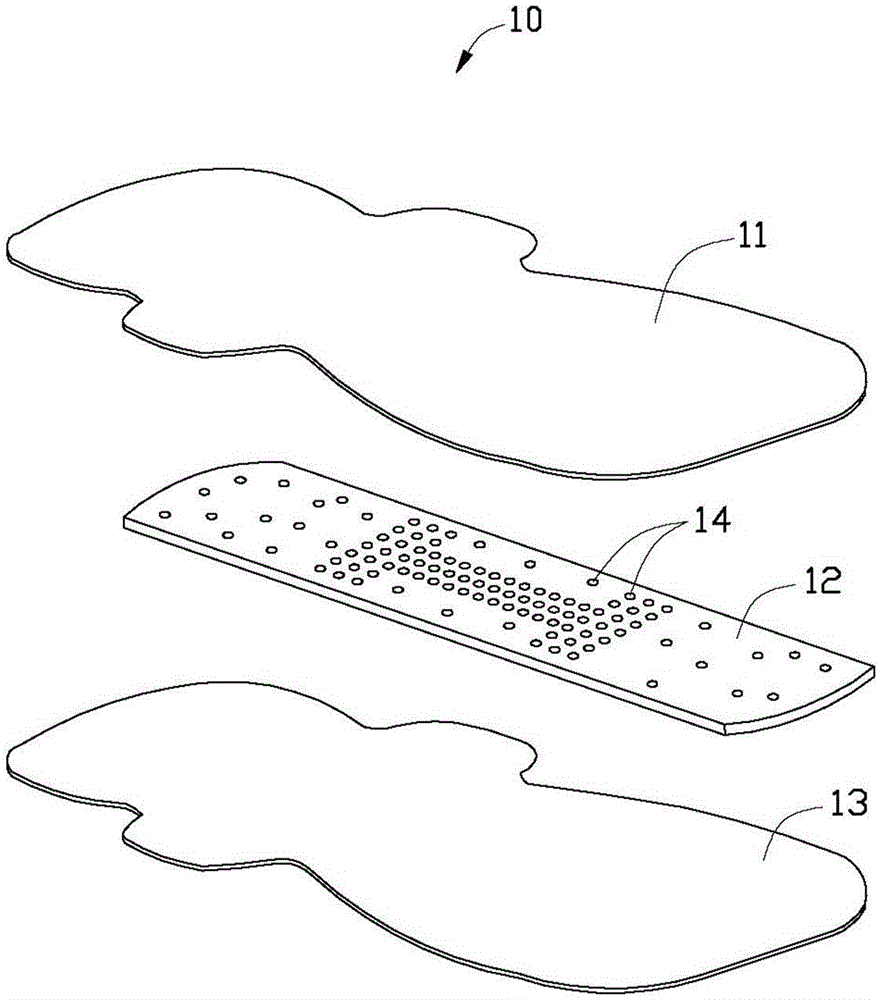

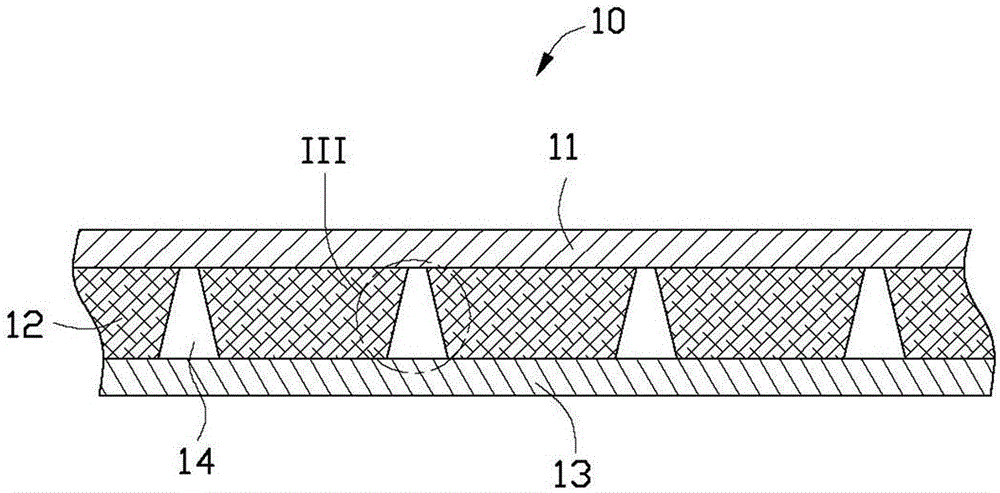

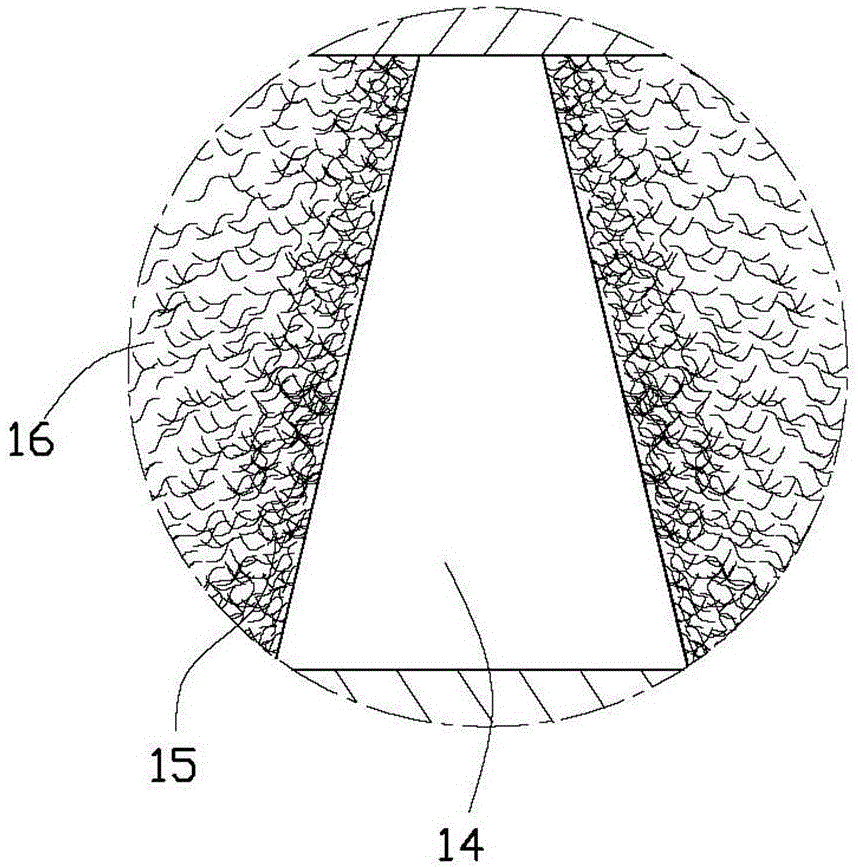

[0027] Please combine figure 1 and figure 2 As shown, the absorbent product 10 provided by the first preferred embodiment of the present invention includes a liquid-permeable top sheet 11, an absorbent core 12 and a liquid-impermeable top sheet sequentially stacked from top to bottom along the thickness direction of the absorbent product 10. Backsheet 13, the absorbent core 12 has two surfaces, one facing the upper surface of the liquid-permeable topsheet 11, and one facing the lower surface of the liquid-impermeable backsheet 13, the absorbent core 12 is provided with multiple A through hole 14 longitudinally penetrating through the absorbent core 12, the through hole 14 has an upper end located on the upper surface of the absorbent core 12 and a lower end located on the lower surface of the absorbent core 12, the diameter of the upper end of the through hole 14 is smaller than that of the lower end aperture.

[0028] The liquid-permeable top sheet 11 is selected from a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com