Environment-friendly dacron dyeing repairing agent

A repairing agent, an environmentally friendly technology, applied in the field of environmentally friendly repairing agents, can solve problems such as chromatic aberration and color flowering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

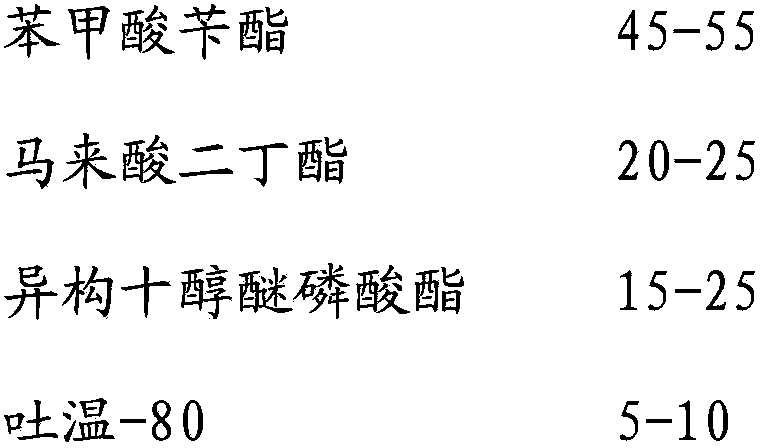

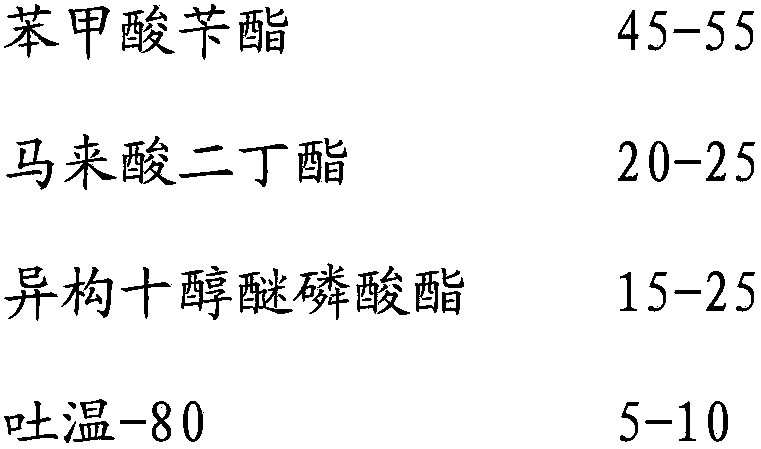

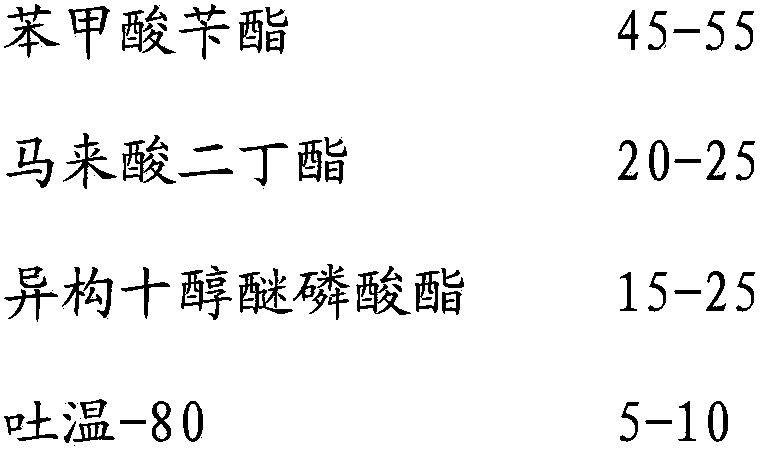

[0018] The environment-friendly polyester dyeing and repairing agent of the present invention is specifically prepared by the following parts by weight: 45 parts by weight of benzyl benzoate, 25 parts by weight of dibutyl maleate, 25 parts by weight of isomerized ten alcohol ether phosphate, and 5 parts by weight of Tween-8.

[0019] The preparation method of the environment-friendly polyester dyeing and repairing agent of the present invention is realized according to the following steps:

[0020] A) fully mixing 45 parts by weight of benzyl benzoate and 25 parts by weight of dibutyl maleate, stirring;

[0021] B) Add 25 parts by weight of isomerized ten alcohol ether phosphate and 5 parts by weight of Tween-80 to the above mixed solution successively, and then the environment-friendly polyester dyeing and repairing agent of the present invention can be obtained.

Embodiment 2

[0023] The environment-friendly polyester dyeing and repairing agent of the present invention is specifically prepared by the following parts by weight: 55 parts by weight of benzyl benzoate, 20 parts by weight of dibutyl maleate, 20 parts by weight of isomerized ten alcohol ether phosphate, and 5 parts by weight of Tween-8.

[0024] The preparation method of the environment-friendly polyester dyeing and repairing agent of the present invention is realized according to the following steps:

[0025] A) fully mixing 55 parts by weight of benzyl benzoate and 20 parts by weight of dibutyl maleate, stirring;

[0026] B) Add 20 parts by weight of isomerized ten alcohol ether phosphate and 5 parts by weight of Tween-80 to the above mixed solution successively, and then the environment-friendly polyester dyeing and repairing agent of the present invention can be obtained.

Embodiment 3

[0028] The environment-friendly polyester dyeing and repairing agent of the present invention is specifically prepared by the following parts by weight: 50 parts by weight of benzyl benzoate, 25 parts by weight of dibutyl maleate, 15 parts by weight of isomerized ten alcohol ether phosphate, and 10 parts by weight of Tween-8.

[0029] The preparation method of the environment-friendly polyester dyeing and repairing agent of the present invention is realized according to the following steps:

[0030] A) fully mixing the benzyl benzoate of 50 parts by weight and the dibutyl maleate of 25 parts by weight, stirring;

[0031] B) Add 15 parts by weight of isomerized ten alcohol ether phosphate and 10 parts by weight of Tween-80 to the above mixed solution successively, and then the environment-friendly polyester dyeing and repairing agent of the present invention can be obtained.

[0032] The environment-friendly polyester dyeing and repairing agent of the invention has an excellen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com