Composition for non-dairy creamer, non-dairy creamer as well as preparation method and application of non-dairy creamer

A technology of non-dairy creamer and its composition, which is applied in the field of non-dairy creamer and its preparation and composition of non-dairy creamer, to achieve the effects of preventing health risks, smooth taste and flavor, and reducing fat intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Weigh raw materials according to the following weights: (grams)

[0058] Sucrose polyester 35g; palm oil 0.5g; glucose syrup 55.6g; sodium caseinate 3.5g; monoglyceride fatty glyceride 2g; diglyceride fatty glyceride 2g; sodium stearoyl lactylate 0.5g; Sodium hexametaphosphate 0.3g; essence 0.45g.

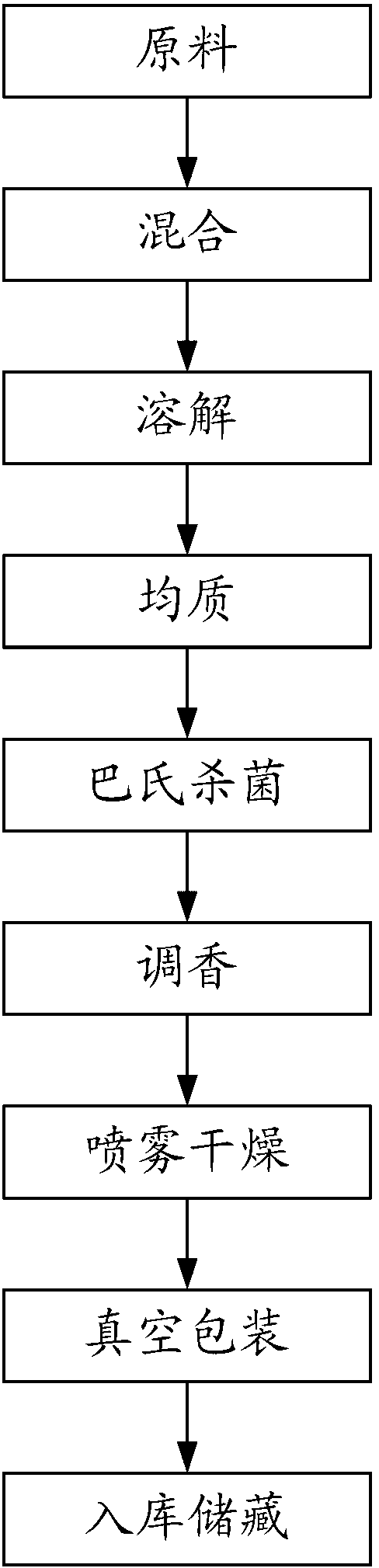

[0059] The preparation method of non-dairy creamer:

[0060] The raw materials are mixed according to the above ratio and dissolved in 500g of distilled water, homogenized, pasteurized, pasteurized usually at 75°C, sterilized for 20s, flavored, spray-dried, the product is aseptically vacuum-packed to obtain non-dairy creamer . Among them, the homogenization pressure is 20MP, the temperature is 65°C, and the number of homogenization is 2 times. And spray drying is carried out under the process conditions of feed rate 460mL / h, inlet air temperature 160°C, outlet air temperature 84°C, and spray pressure 25Mpa.

Embodiment 2

[0062] Weigh raw materials according to the following weights: (grams)

[0063] Sucrose polyester 30g; palm oil 3g; glucose syrup 58.5g; sodium caseinate 3g; monoglyceride fatty glyceride 4g; diglyceride fatty glyceride 0.1g; sodium stearoyl lactylate 0.2g; Sodium metaphosphate 0.4g; essence 0.3g.

[0064] The preparation method of non-dairy creamer:

[0065] The raw materials are mixed according to the above ratio and dissolved in 590 g of distilled water. After homogenization, pasteurization, flavoring and spray drying, the product is subjected to aseptic vacuum packaging to obtain non-dairy creamer. Among them, the homogenization pressure is 15MP, the temperature is 80°C, and the number of homogenization times is 1 time. And spray drying is carried out under the process conditions of feed rate 400mL / h, inlet air temperature 120°C, outlet air temperature 90°C, and spray pressure 20Mpa.

Embodiment 3

[0067] Weigh raw materials according to the following weights: (grams)

[0068] Sucrose polyester 10g; corn oil 15g; glucose syrup 30g; sodium caseinate 2g; monoglyceride fatty glyceride 5g; diglyceride fatty glyceride 4g; sodium stearoyl lactylate 0.1g; Sodium 0.2g; essence 0.5g.

[0069] The preparation method of non-dairy creamer:

[0070] The raw materials are mixed according to the above ratio and dissolved in 270 g of distilled water. After homogenization, pasteurization, flavoring and spray drying, the product is subjected to aseptic vacuum packaging to obtain non-dairy creamer. Among them, the homogenization pressure is 30MP, the temperature is 60°C, and the number of homogenization times is 3 times. And spray drying is carried out under the process conditions of feed rate 500mL / h, inlet air temperature 180°C, outlet air temperature 80°C, and spray pressure 30Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com