Method and apparatus for simulating torque efficiency of an internal combustion engine with multiple injections of fuel in one combustion stroke

A technology of multiple injection and combustion strokes, applied in fuel injection control, combustion engines, internal combustion piston engines, etc., can solve the problems of insufficient torque accuracy of internal combustion engines, and achieve the effect of accurate simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

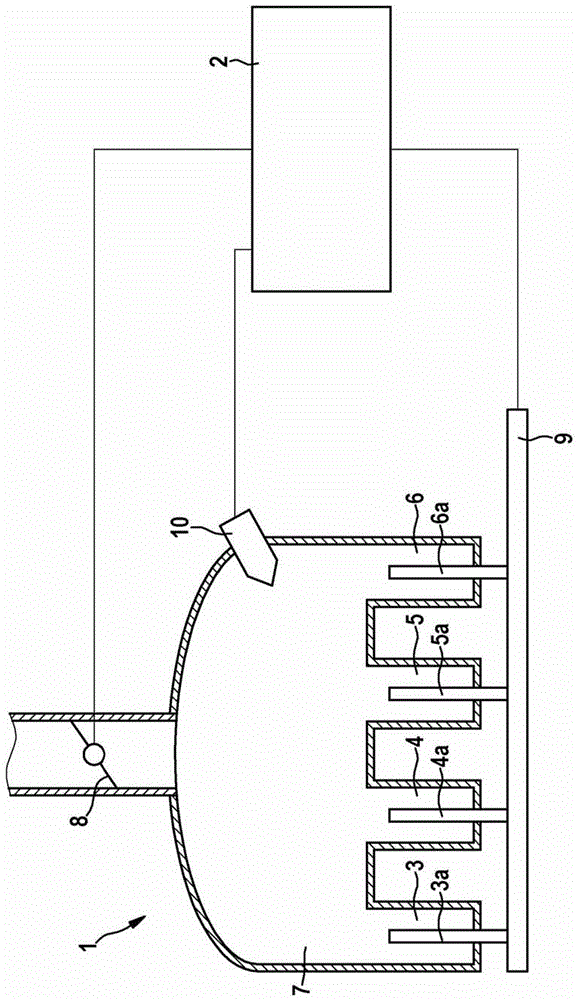

[0016] figure 1 A schematic diagram of an internal combustion engine 1 , which is controlled by a control unit 2 , is shown. Internal combustion engine 1 consists of four cylinders 3 , 4 , 5 , 6 which are interconnected via an intake manifold 7 . Each cylinder 3, 4, 5, 6 has a connecting rod 3a, 4a, 5a, 6a connected to a crankshaft 9 and a fuel injection valve 10, in figure 1 Only one of these fuel injection valves is shown as an example. Furthermore, connected to the suction line 7 is an air supply line 11 in which a throttle valve 8 is arranged.

[0017] Here the crankshaft 9 and the injection valve 10 are electrically connected with the throttle valve 8 and the control device, and the control device will adjust the air input amount through the throttle valve 8 according to the position of the crankshaft 9 and adjust the pair of cylinders 3, 4, 5 through the injection valve 10, 6 fuel input.

[0018] The explosive combustion of the fuel injected into the internal combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com