Automatic sorting system

An automatic sorting system and sorting line technology, applied in sorting and other directions, can solve problems such as low operating efficiency, and achieve the effects of improved operating efficiency, simple design and high sorting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

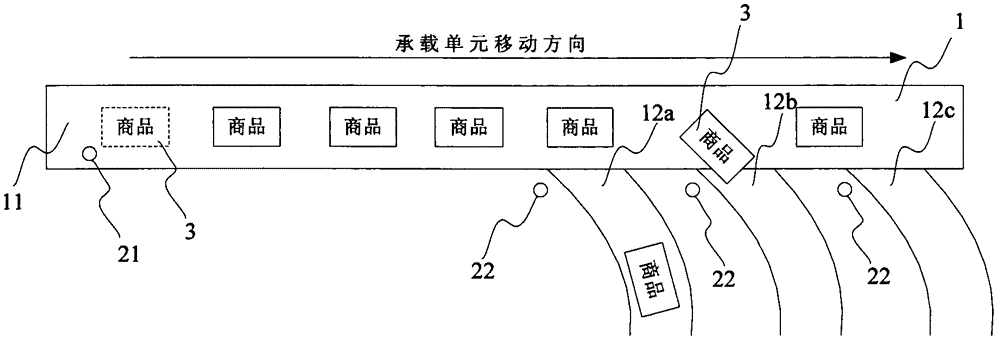

[0033] refer to figure 1 As shown, the automatic sorting system in this embodiment includes a sorting line 1, a control unit (not shown in the figure) and a plurality of sorting actuators (not shown in the figure). This sorting line 1 has a sorting line inlet 11 and a plurality of sorting line outlets (such as figure 1 12a, 12b, 12c in , but of course not limited to the case of 3 sorting line outlets), these sorting line outlets lead to each branch of the sorting line 1 respectively.

[0034] figure 1 The sorting line in can be a push block type sorting line, which has a plurality of load-carrying units in the form of chain plates, and these chain plates are used to carry goods along the figure 1 Move in the direction shown by the arrow in the center. Of course, according to the different sizes of the goods, the number of chain plates carrying a product can be one or more. or, figure 1 The sorting line can also be a tray-type sorting line, and the carrier unit will be in t...

Embodiment 2

[0044] In this embodiment, each second RFID tag reading unit is not only used to read the RFID tag to know the arrival of the commodity, but also to set the end of the sorting path as the branch where the second RFID tag reading unit is located. The queue length of the sorting line exit and the commodities that have arrived at the sorting line exit are fed back to the control unit in real time, so that the control unit can know the busyness of each sorting line exit and wait in line to be sorted into and out. The longer the queue of goods on the road, the busier the exit of the sorting line will be.

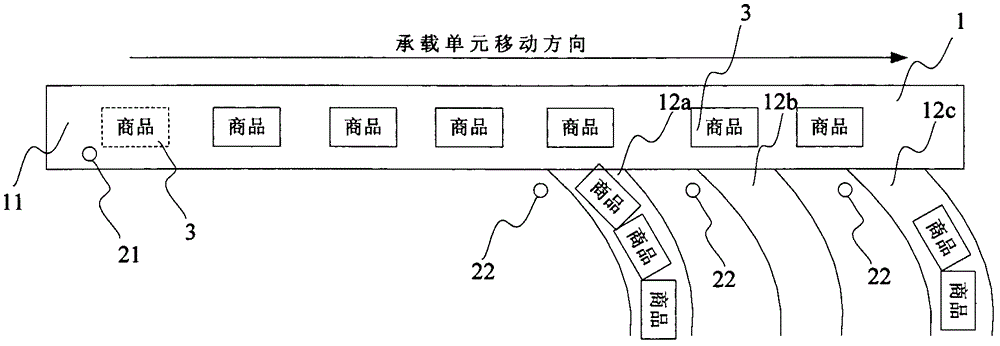

[0045] For example, refer to figure 2 The schematic structure of the sorting line 1 in , the feedback information obtained by the control unit may be: currently, there are 3 items in line at the sorting line exit 12a, there is no product waiting at the sorting line exit 12b, and the sorting line exit 12c There are 2 items in line.

[0046] In this case, if an order contains at...

Embodiment 3

[0049] The only difference between this embodiment and Embodiment 1 and Embodiment 2 is that: at this time, the RFID tag is only set on the product, or the RFID tag is only set on the carrying unit of the product. Correspondingly, the first RFID tag reads As long as the fetching unit and each second RFID tag reading unit read the RFID tag on the commodity or the carrying unit of the commodity, the control unit will judge that the commodity has entered the sorting line 1 or has reached a predetermined location. Sorting line exit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com