Vehicle rearview mirror factory inspection device

A technology for factory inspection and rearview mirror, which is used in measuring devices, optical instrument testing, machine/structural component testing, etc. It can solve the problems of long testing process, low efficiency, low detection rate, etc. The effect of high detection efficiency and high detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

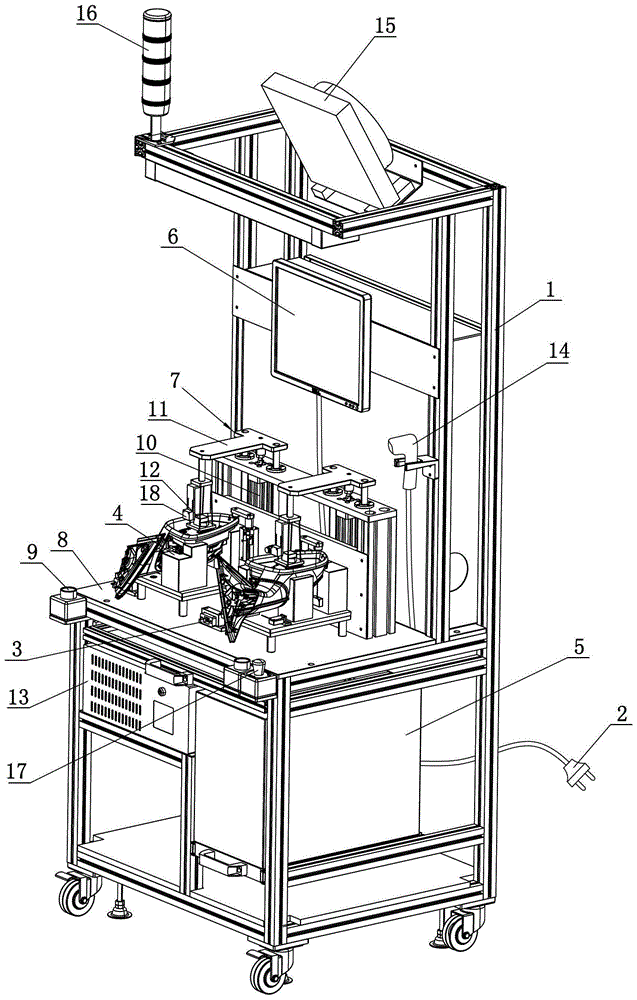

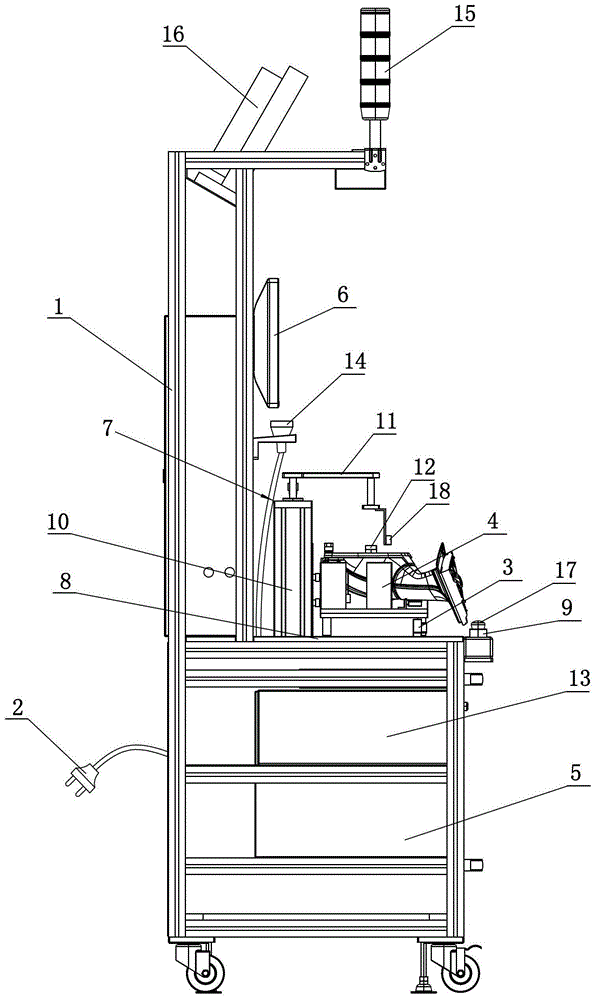

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0016] Such as figure 1 and figure 2 A kind of vehicle rearview mirror ex-factory detection device shown, it comprises frame 1, power connector 2, rearview mirror connector 3 and rearview mirror clamp 4, and described rearview mirror clamp 4 is fixed on the frame 1, It also includes a control box 5, a display screen 6 and a mirror position sensing mechanism 7. The frame 1 is provided with a workbench 8. Usually, in order to save space, the workbench 8 is provided with two stations, that is, two A rearview mirror fixture 4, two rearview mirror joints 3 and two mirror surface position sensing mechanisms 7, these three are set up in one-to-one correspondence respectively (a rearview mirror clamp 4, a rearview mirror joint 3 and a mirror surface position induction Mechanism 7 is a group), the rearview mirror fixture 4 includes a groove that matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com