Anti-typhoon control method for wind power plant

A technology for wind farms and control methods, which is applied to the control of wind turbines, wind power generation, wind turbines, etc., which can solve the problems of high backup power maintenance costs, high investment costs, and high power consumption, and achieve improved yaw reliability , Sufficient response time, and the effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

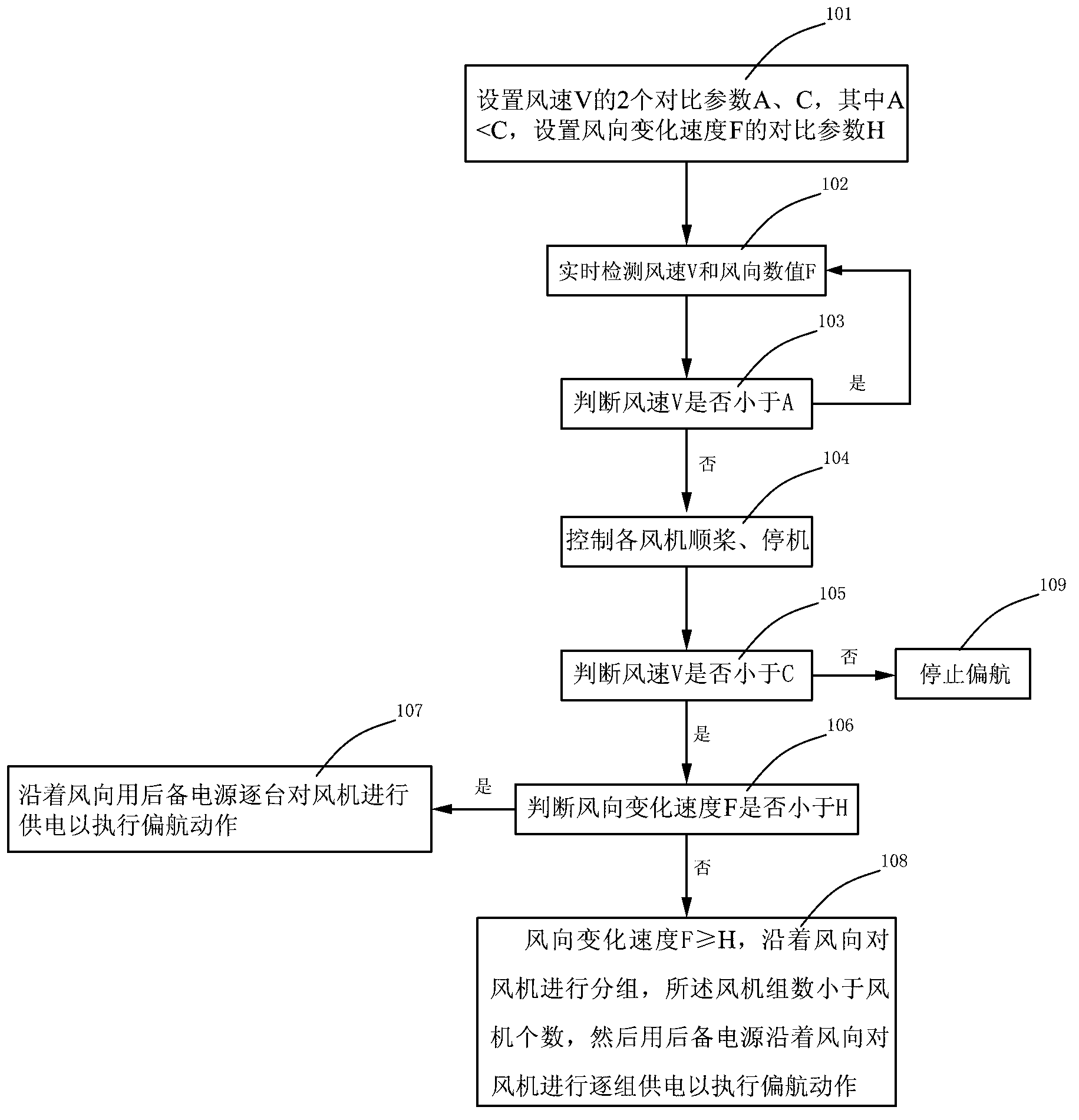

[0045] Embodiment 1, taking A=20m / s, C=35m / s, F=8 degrees / s as an example to describe this control method in detail.

[0046]As mentioned above, when the wind speed is below 20m / s, anti-typhoon control, feathering and shutdown are not required.

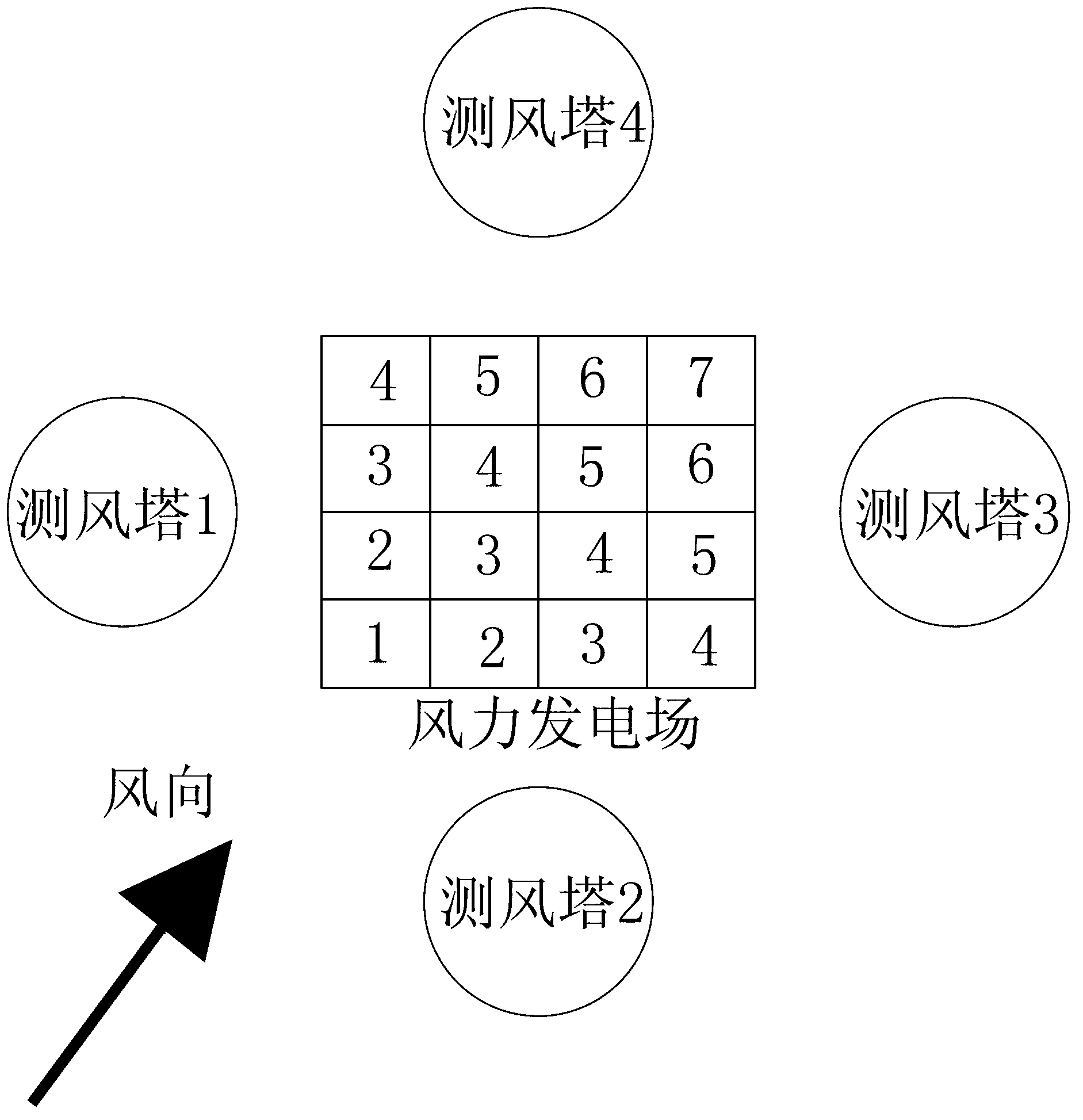

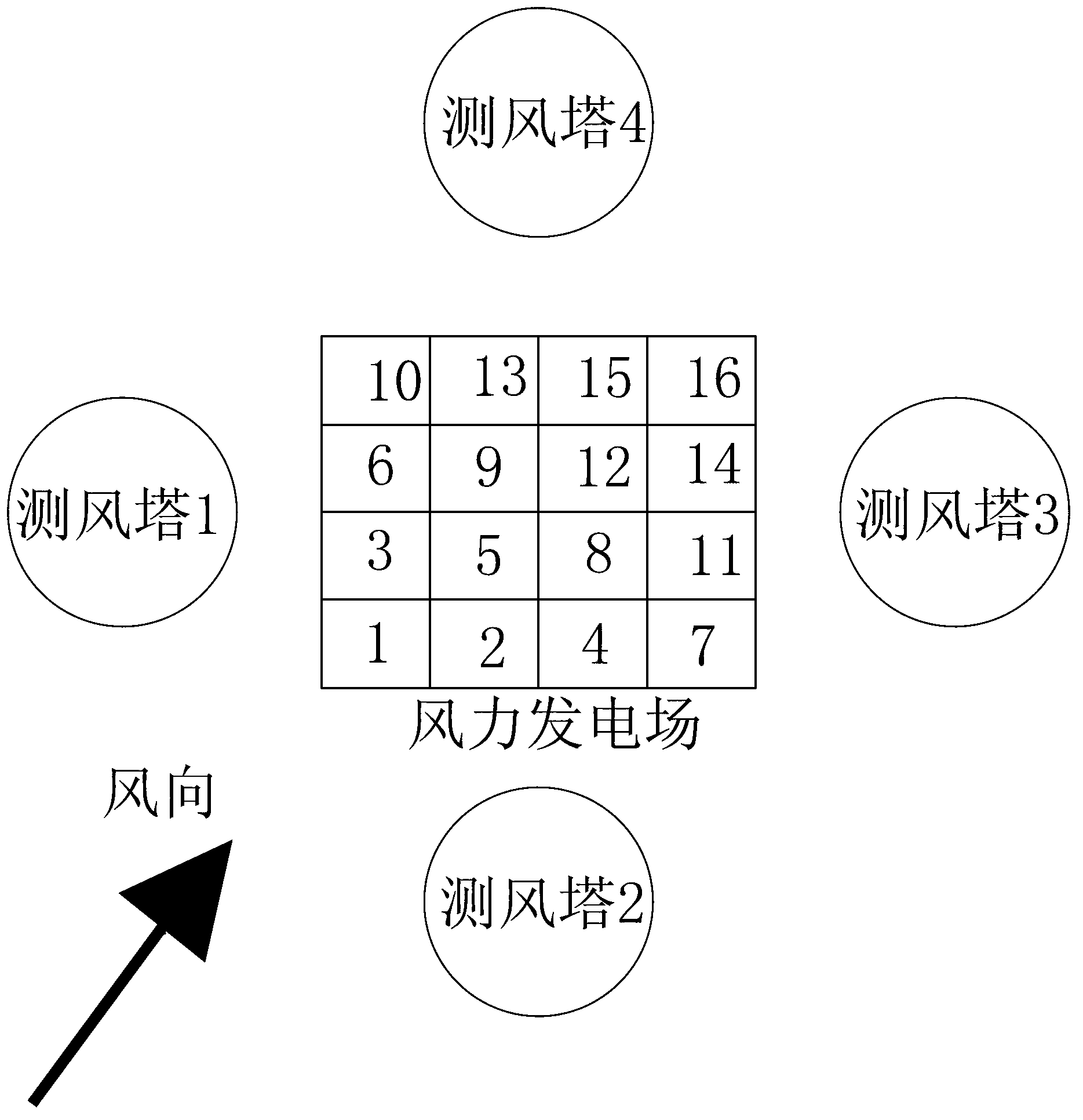

[0047] If the typhoon is coming, it is detected that the wind speed V=30m / s, then feather, stop and execute this control method, when it is actually detected that the wind direction change speed F is less than 8 degrees / s, that is, the wind direction changes slowly, perform step 107, combined with image 3 The coming direction of the wind is shown, and the fans numbered 1, 2, 3, 4, 5...16 are supplied with power in order to perform the yaw action; when the wind direction change speed F is detected to be greater than 8 degrees / s , that is, the wind direction changes rapidly, execute step 108, combining figure 2 As shown, power is supplied to the wind turbines with group numbers 1, 2, 3, 4...7 in sequence to perform the yaw action.

Embodiment 2

[0048] Embodiment 2, taking A=25m / s, C=35m / s, F=10 degrees / s as an example to describe this control method in detail.

[0049] As mentioned above, when the wind speed is below 25m / s, anti-typhoon control, feathering and shutdown are not required.

[0050] When a typhoon comes and detects that the wind speed V=30m / s, feather the propeller, shut down and execute this control method. When it is actually detected that the wind direction change speed F is less than 10 degrees / s, that is, the wind direction changes slowly, perform step 107, combining image 3 The coming direction of the wind shown is to supply power to the fans numbered 1, 2, 3, 4, 5...16 in order to perform yaw action; when the wind direction change speed F is detected to be greater than 10 degrees / s , that is, the wind direction changes rapidly, execute step 108, combining figure 2 As shown, power is supplied to the wind turbines with group numbers 1, 2, 3, 4...7 in sequence to perform the yaw action.

Embodiment 3

[0051] Embodiment 3, taking A=30m / s, C=50m / s, F=15 degrees / s as an example to describe this control method in detail.

[0052] As mentioned above, when the wind speed is below 30m / s, anti-typhoon control, feathering and shutdown are not required.

[0053] When a typhoon comes and detects that the wind speed V is between 30m / s and 50m / s, then feather, stop and execute this control method. When the actually detected wind direction change speed F is less than 15 degrees / s, that is, the wind direction changes slowly , step 107 can be executed to combine image 3 The coming direction of the wind shown, sequentially supply power to the fans numbered 1, 2, 3, 4, 5...16 to perform yaw action; when it is detected that the wind direction change speed F is greater than 15 degrees / s , that is, the wind direction changes rapidly, execute step 108, combining figure 2 As shown, power is supplied to the wind turbines with group numbers 1, 2, 3, 4...7 in sequence to perform the yaw action. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com