Foam shoe die for making soles

A shoe mold and mold cavity technology is applied in the field of shoe-making molds, which can solve the problems of affecting the performance of soles, breaking, and unsatisfactory structural design of blowing shoe molds, so as to improve the overall elasticity and easy bending performance, improve performance, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

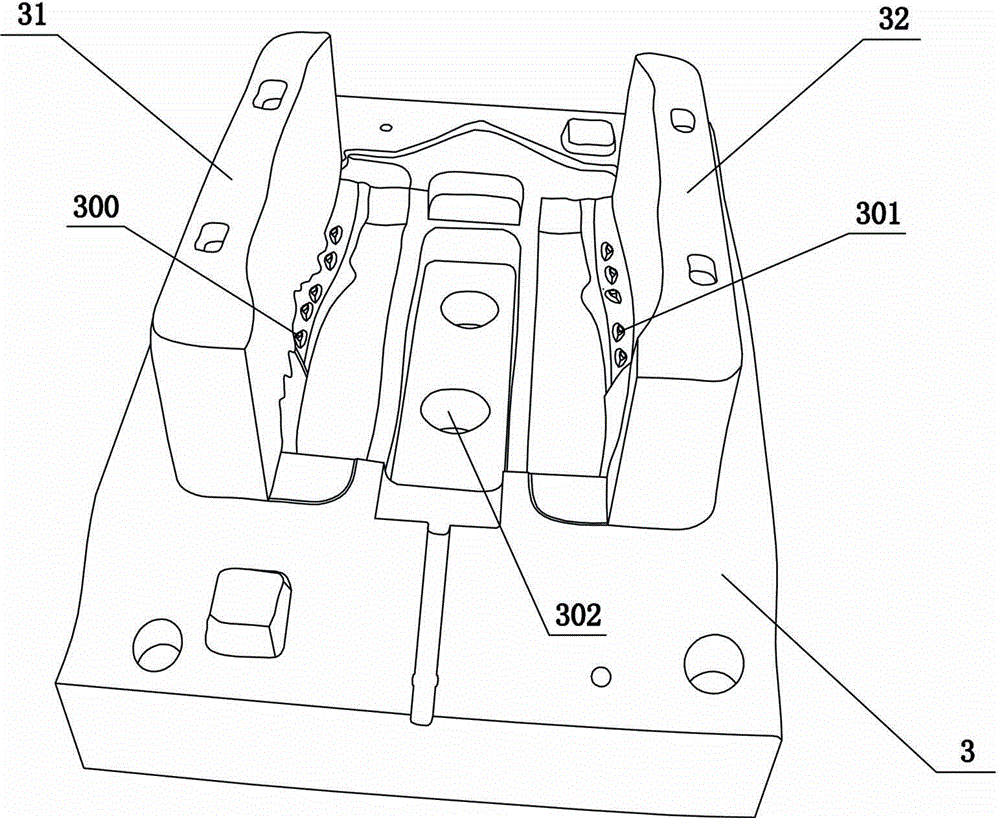

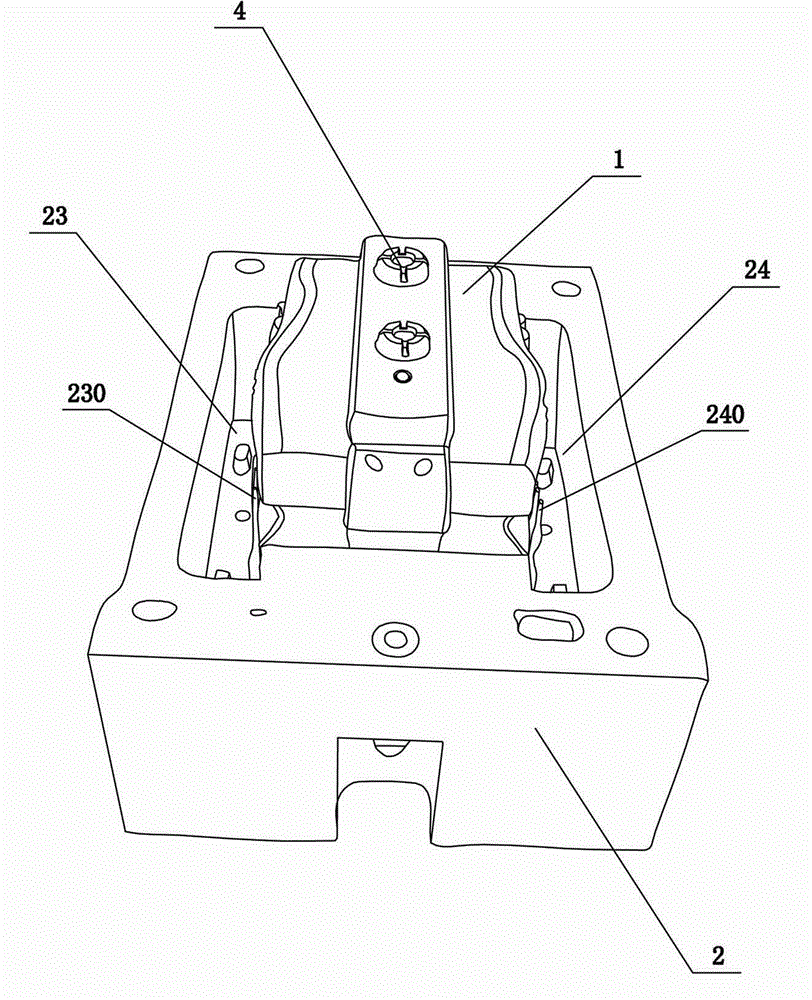

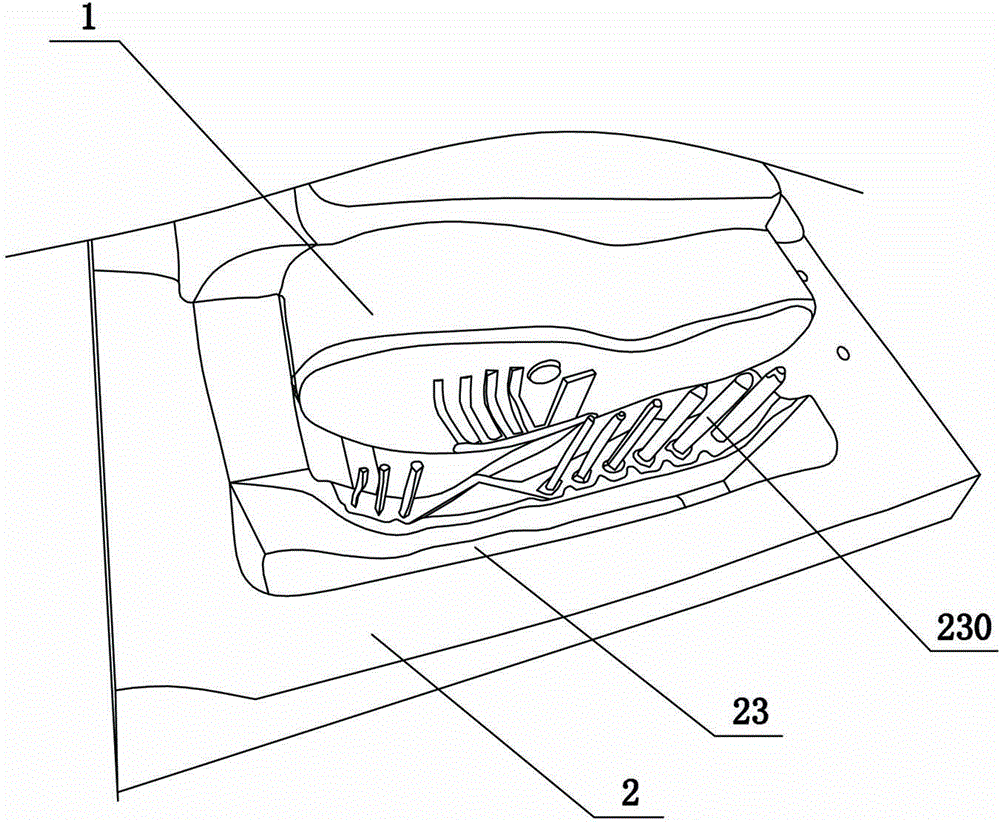

[0018] refer to figure 1 , figure 2 , image 3 , Figure 4 , a foam shoe mold for making soles, including a mold core 1, an upper mold 2 with an upper mold cavity, and a lower mold 3 that cooperates with the upper mold 2 and has a lower mold cavity, and also includes upper and lower molds Exhaust port (not shown in the figure) for the gas in the chamber to escape. The upper mold 2 is provided with a material injection channel 21 and an air intake channel 22 . The left and right sides of the lower mold cavity are respectively provided with left and right bumps 31 and 32 for forming the shape of the entire sole bottom surface. The mold core 1 is assembled in the middle of the upper mold cavity, and the left and right grooves 23, 24 corresponding to the left and right bumps 31, 32 are formed on the left and right sides of the mold core 1, when the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com