Electric push rod drive controlled flexible gripper with plate spring frameworks

An electric push rod and drive control technology, which is applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., can solve the problems of deformation force, increase of leaf springs, and difficult bending of leaf springs, so as to reduce the cross-sectional area of leaf springs, reduce the The small force part, the effect of increasing the gripping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

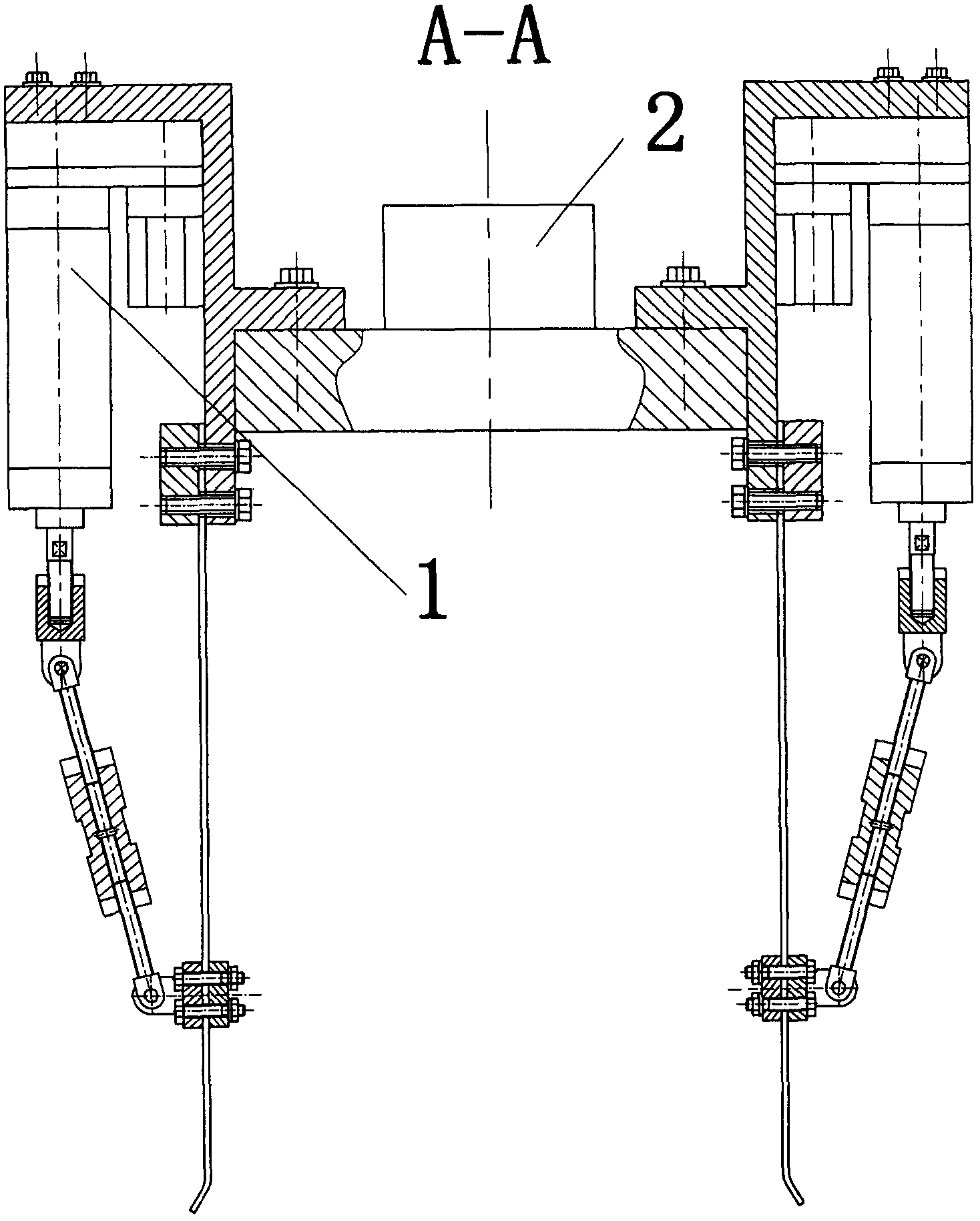

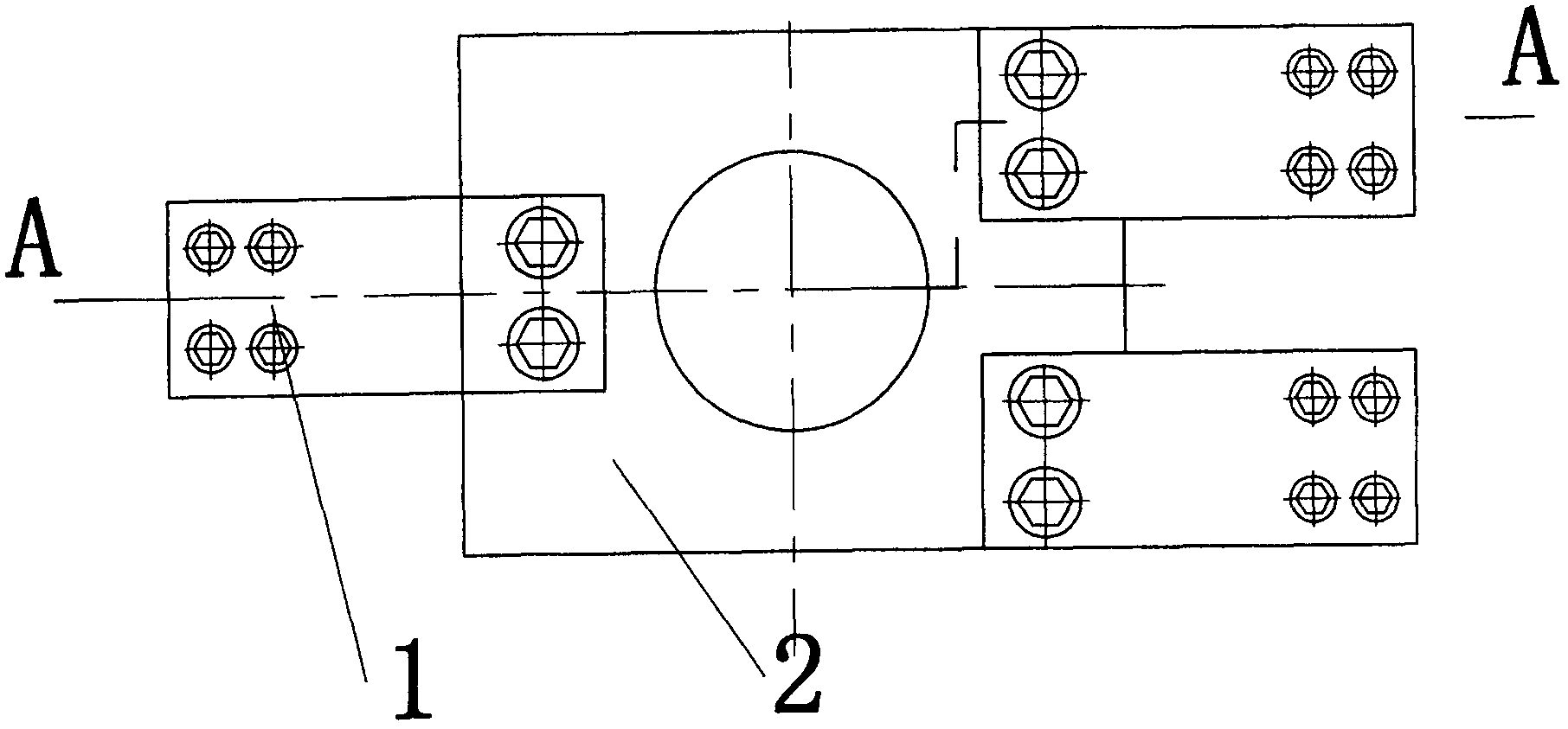

[0024] Below is working principle and working process of the present invention:

[0025] A section of the plate spring 4a (from below the clamping point of the root plate 2a and the clamp block 3a to above the clamping point of the pressure plate 6a and the hinge support 7a) is a deformed section, which is driven by an electric push rod to produce large deformation; the pressure plate 6a and the hinge support The lowermost end of the lower side of the leaf spring 4a clamped by the seat 7a is a curved surface and is a grasping section, and the grasping contact part of a complex object is just in the grasping section of the leaf spring 4a.

[0026] The electric push rod 1a is energized, and its push rod moves downward, thereby driving the two-force rod (composed of the left threaded hinge rod 8a, the threaded sleeve 9a, and the right threaded hinge rod 10a), and overcomes the elastic force to make the plate spring 4a bend, and the plate spring 4a grabs Take the segment to touch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com