Method for operating an internal combustion engine having at least two cylinders

An internal combustion engine and cylinder technology, applied in the field of gas engines, can solve problems such as pressure can not be detected correctly, unsuitable, large time delay, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

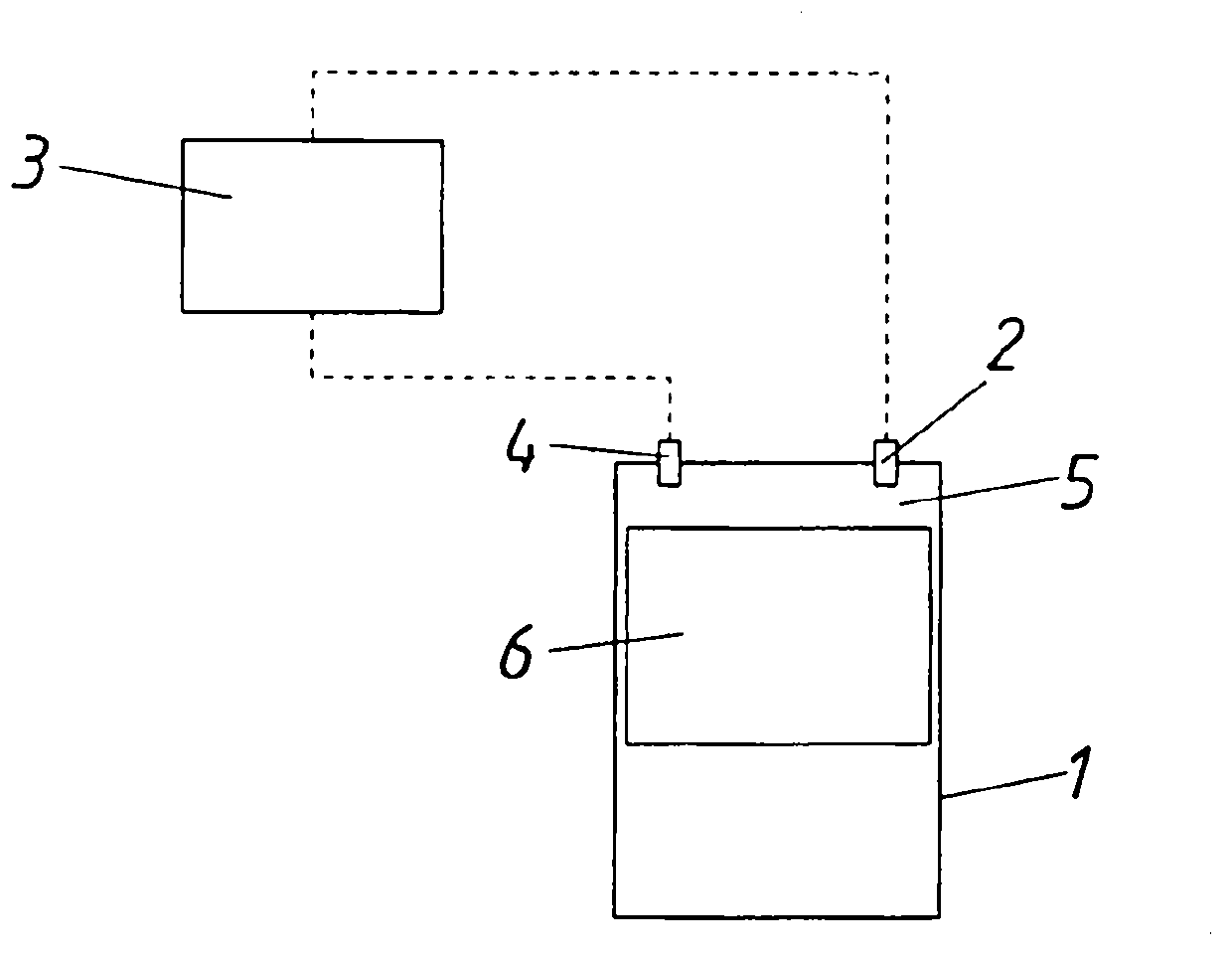

[0036] figure 1 A cylinder 1 of an internal combustion engine is shown schematically with a piston 6 located therein. The introduction device 4 serves here to inject steam gas into the combustion chamber 5 . The cylinder pressure sensor 2 measures the pressure in the combustion chamber 5 of the cylinder 1 , for example continuously or discontinuously in time and / or in relation to the angle of the crankshaft (not shown here) connected to the piston 6 The data are supplied to a control or regulation device 3 for controlling or regulating the power and / or torque and / or rotational speed of the internal combustion engine. Depending on the desired control variable, a corresponding quantity of fuel for cylinder 1 is metered by control or regulating device 3 and injected into combustion chamber 5 by means of introduction device 4 . In this example, the control or regulating device 3 together with the introduction device 4 therefore assumes the role of a fuel metering device.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com