A method for controlling the plate chain speed of an automatic battery packer

An automatic packing machine and speed control technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems affecting the working efficiency of the packing machine and the quality of finished products, and achieve convenient debugging and convenient speed Control, achieve simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

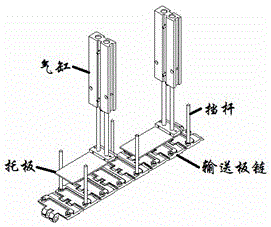

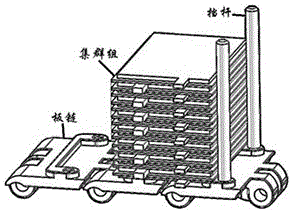

[0034] Step (1): In the equipment debugging mode, when the plate chain is continuously moved, measure the number of pulses Y required by the stepper motor when moving a distance ΔL between the stopper rods.

[0035] Step (2): In the normal operation mode of the equipment, when the plate chain conveys the group, use the multi-stage state equation and the observation equation to express the speed state of the stepper motor at each moment:

[0036] Observation equation: N(t)=l(t)÷ρ

[0037] Equation of state: P(t)=P 0 +K 1 ×t acceleration stage (P(t)1 , N(t)

[0038] P(t)=P 1 Uniform velocity stage (P(t)≥P 1 , N(t)

[0039] P(t)=P 1 -K 2 ×(t-t 2 ) deceleration phase (N(t)≥Y, D=0)

[0040] P(t)=P 2 Stable stage (N(t)≥Y, D=1)

[0041] Where l(t) is the number of pulses that the controller has sent to the stepper motor at time t, t 2 is the deceleration start time. ρ is the percentage of pre-deceleration (ρ>0 and ρ0 is the starting speed, P 1 is the maximum speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com