LC-type short-tail heat-shrink-tube-free optical fiber moving connector

A technology of movable connector and heat shrinkable tube, which is applied to the coupling of optical waveguides and other directions, can solve the problems of inconvenient installation and use, high manufacturing cost, complex structure, etc., and achieves the effect of simple structure, avoidance of falling off, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

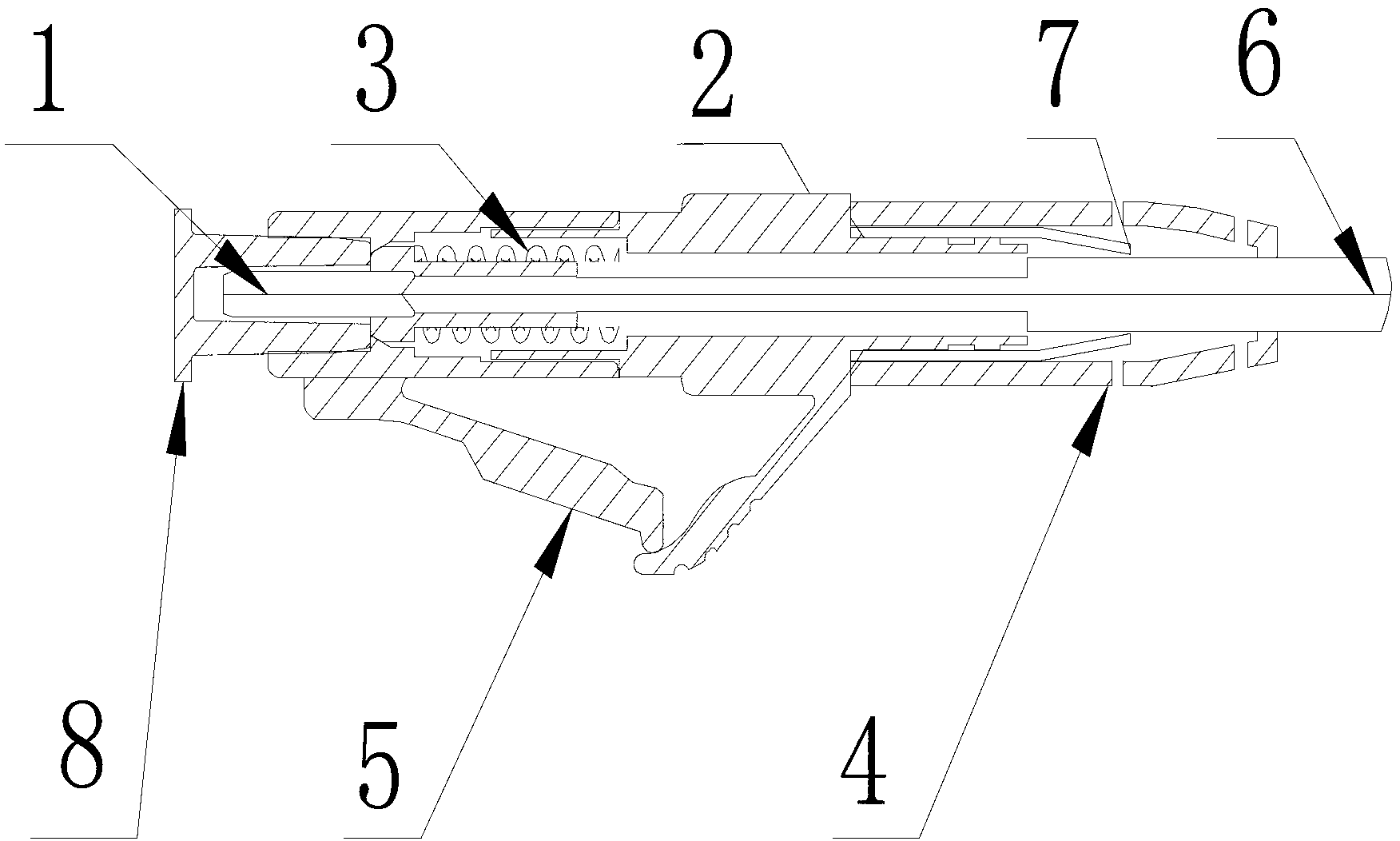

[0016] The content of the invention will be explained in detail below in conjunction with the accompanying drawings.

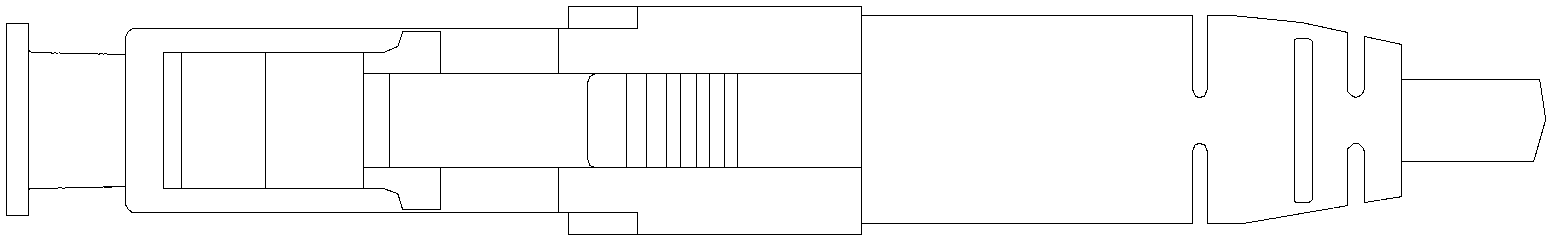

[0017] refer to figure 1 , figure 2 , the present invention includes a ferrule 1, a connector 2, a spring 3, a boot 4, a housing 5, a bare optical fiber 6 and a crimping ring 7, the connector 2 is provided with a buckle, and the head of the connector 2 is connected to the housing 5 , the shell 5 passes through the ferrule 1 and is stuck on the buckle, the tail end of the connector is provided with a riveting part, the tail end of the connector 2 is connected with the boot 4, and the boot 4 is a hollow cylinder The outer surface of one end shrinks inwardly, the shell 5, the connector 2 and the boot 4 form a cavity, the spring 3 and the ferrule 1 are placed in the cavity, the inner wall of the connector 2 is provided with a boss, and the spring 3 is arranged on the connector 2 On the boss of the inner wall, one end of the bare optical fiber 6 of the optical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com