Temperature control device of flue gas desulfurizing and acid-making hot blast stove and control method

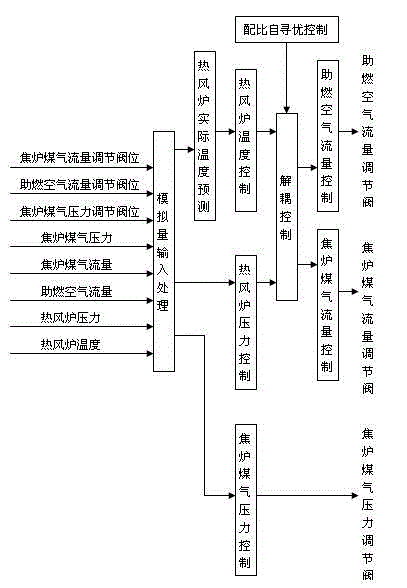

A hot blast stove and flue gas technology, which is applied in the field of temperature control technology of hot blast stove for flue gas desulfurization and acid production, can solve the problems of lag in online temperature detection of hot blast stove, unstable temperature, inability to meet constant temperature hot blast, etc., so as to improve fast response performance and Adaptability, improving overall control accuracy, and the effect of significant technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

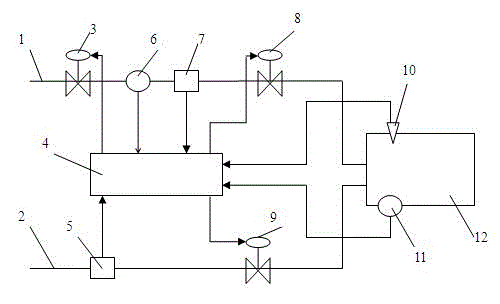

[0011] Example: figure 1 As shown, the flue gas desulfurization acid hot blast furnace temperature control device includes a coke oven gas input pipe 1, a combustion air input pipe 2 and a flue gas desulfurization acid hot blast stove 12 connected to the two gas input pipes. Coke oven gas pressure regulating valve 3, coke oven gas pressure sensor 6, coke oven gas flow sensor 7 and coke oven gas flow regulating valve 8 are installed on the gas input pipeline 1; combustion air flow sensor 5 and A combustion-supporting air flow regulating valve 9; a hot-blast stove temperature sensor 10 and a hot-blast stove pressure sensor 11 are installed on the hot-blast stove 12 for flue gas desulfurization and acid production; Gas pressure regulating valve 3, coke oven gas pressure sensor 6, coke oven gas flow sensor 7 and coke oven gas flow regulating valve 8, and the combustion air flow sensor 5 and combustion air flow regulating valve 9 on the combustion air input pipeline 2, and The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com