Double input and multiple output gearbox structure

A gearbox structure and multi-output technology, which is applied in the direction of gear transmission, belt/chain/gear, transmission parts, etc., can solve the problems that the gearbox cannot be applied and the application field is limited, and achieve light weight and small increase in cost , the effect of small axial distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

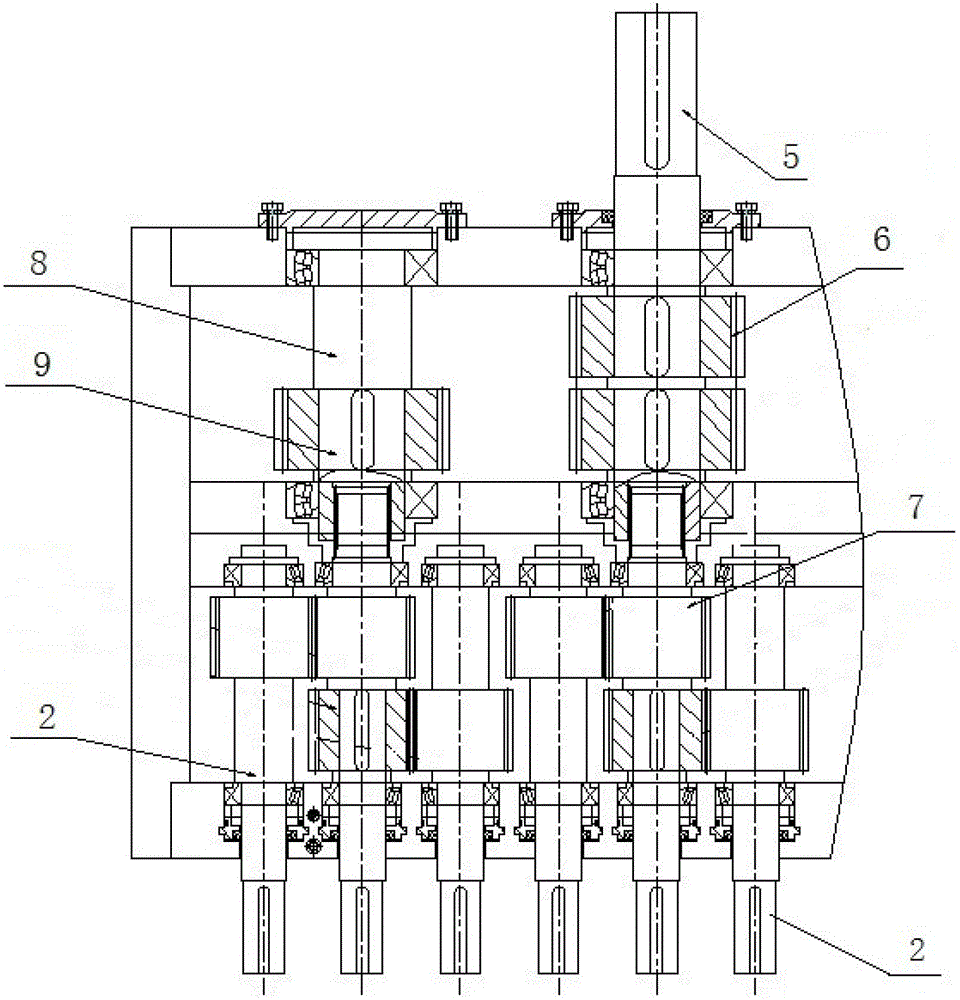

[0019] Such as figure 1 , figure 2 As shown, a double-input multi-output gear box structure includes a gear box. The gear box is divided into an upper box body 1, a middle box body 3 and a lower box body 4. The middle box body is provided with a dual-input input shaft 5, And a multi-output device connected with the input shaft 5 transmissions.

[0020] In this embodiment, the multi-output device includes upper and lower rows of output shafts 2 , and each row includes several output shafts 2 . Considering the actual situation, the number of output shafts in one row is one less than the number of output shafts in the other row.

[0021] Several input gears 6 are arranged on the input shaft, and each input gear 6 is transmission-connected to an output shaft group A, and the input shaft is directly connected to an output shaft group B.

[0022] In specific cases, two input gears 6 are arranged on the input shaft, and the two input gears 6 are transmission-connected to two outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com