Valve lift adjustment device

A technology for regulating devices and valve lifts, which is applied to valve devices, engine components, machines/engines, etc., and can solve problems such as load application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

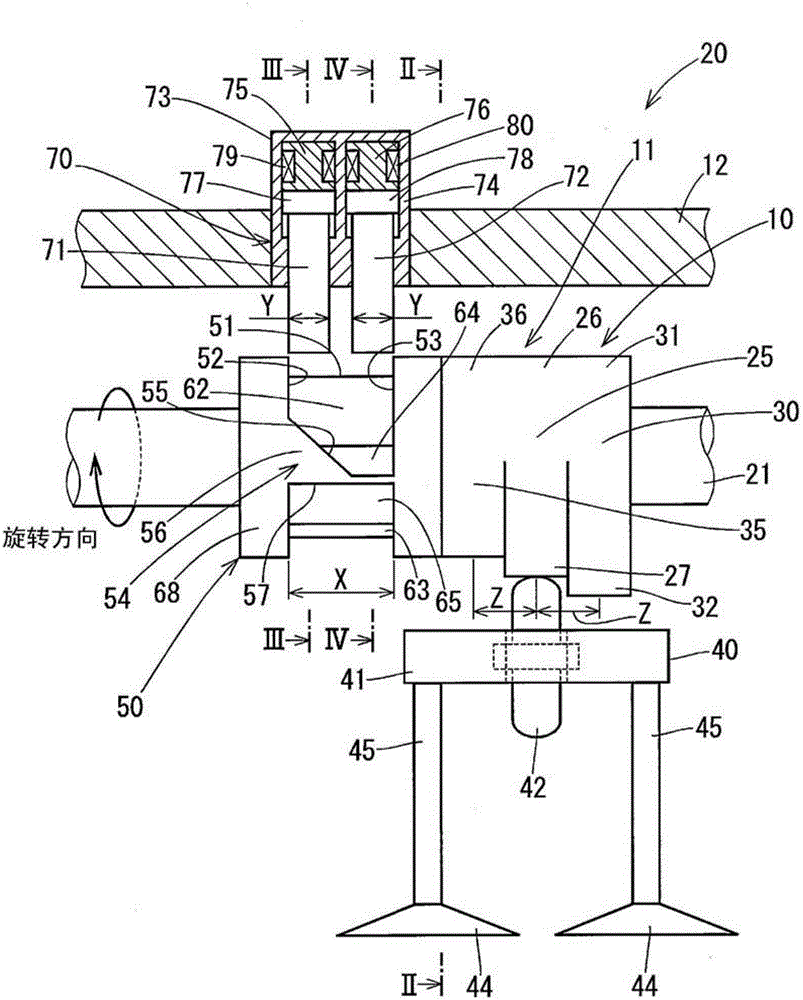

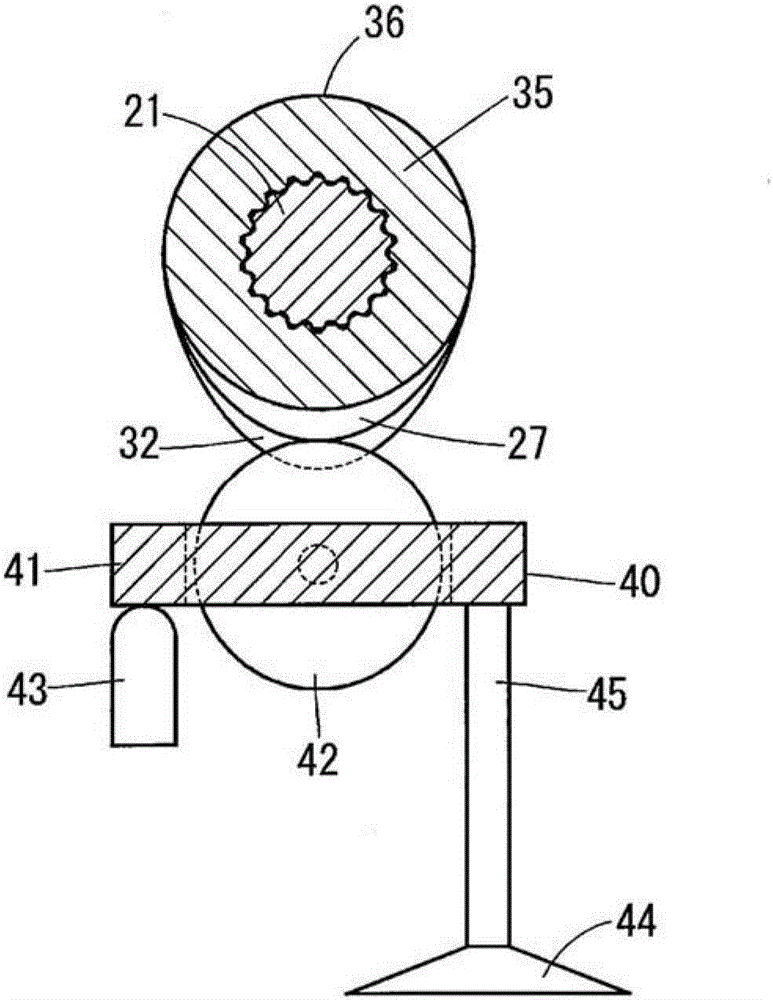

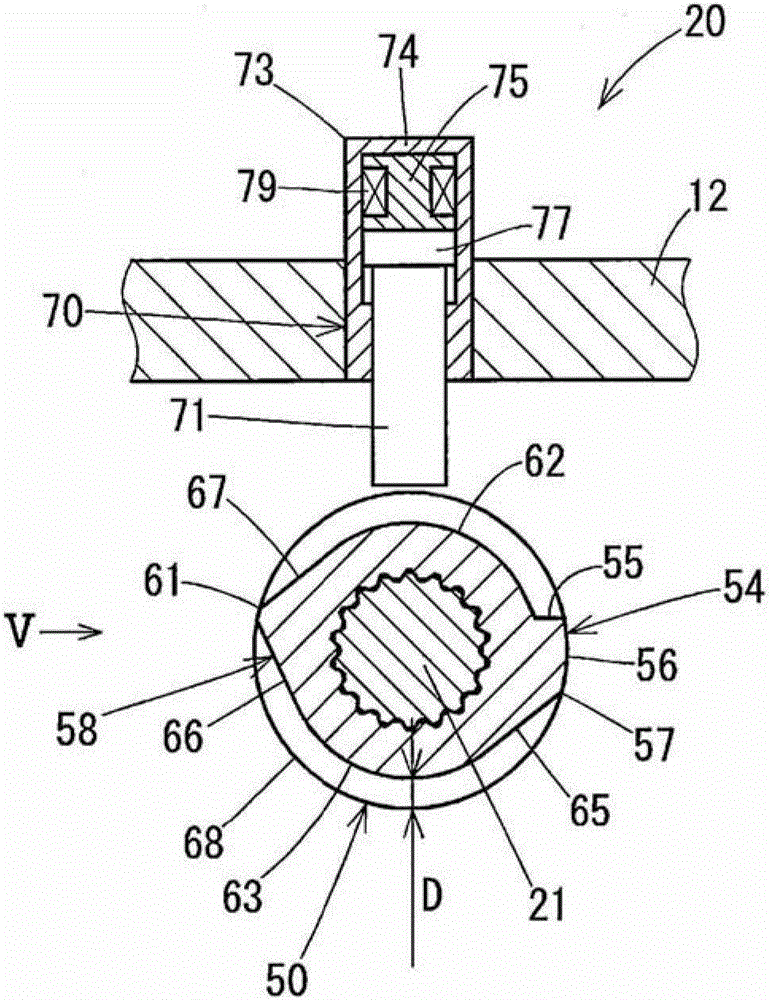

[0026] Embodiments will be described below with reference to the accompanying drawings. The valve lift adjusting device according to the embodiment is a cam-switching type variable valve mechanism, and in such as figure 1 used in the valve system shown. The valve system 20 is a system for opening or closing an intake valve 44 of an internal combustion engine.

[0027] Such as Figures 1 to 5 As shown, the valve system 20 includes a camshaft 21, a low rotation cam 25, a high rotation cam 30, a low load cam 35, a roller lock 40, a lash adjustment device 43, an intake valve 44, a sliding device 50, and an actuating device. 70.

[0028] The low rotation cam 25 , the high rotation cam 30 , the sliding device 50 , and the actuating device 70 constitute the first valve lift adjustment device 10 . In the first valve lift adjusting device 10, the low-rotation cam 25 may correspond to a "first plate cam", and the high-rotation cam 30 may correspond to a "second plate cam".

[0029]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com