Intensive storage and sorting method and equipment for bagged items

A bagged article storage technology, which is applied in the field of bagged article storage, sorting and outbound, can solve the problems of high labor intensity, low operation efficiency, and many people, and achieve compact arrangement, simple structure, and large storage capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

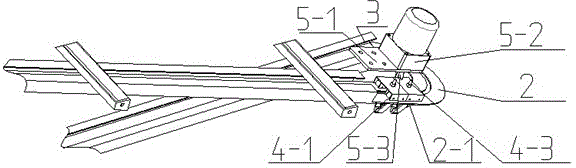

[0038] Embodiment 1, the clip control and drive mechanism of the sorting device uses a motor to toggle the clip device, see the attached Figure 2~6 .

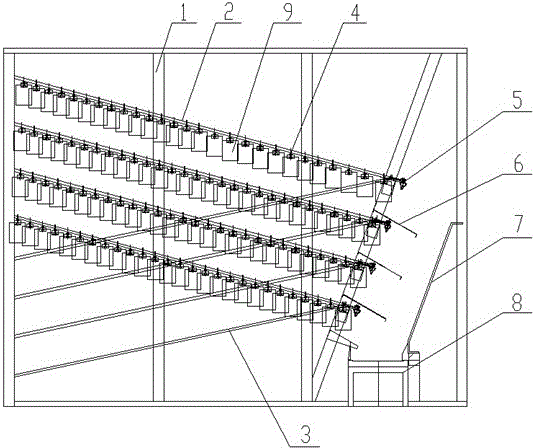

[0039] The bagged article sorting device is composed of a shelf 1, a storage slide 2, a recovery slide 3, a tackle 4, a sorting device 5, a transition slide 6, a blocking slide 7, and a conveying device 8.

[0040] The storage slideway 2 and the recovery slideway 3 are both processed by two half tanks, installed on the beam of the shelf, connected by a circular track, in the shape of ">", that is, the end of the storage slideway 2 and the The starting end of the recovery slideway 3 is connected; multi-layer and multi-row storage slideway 2 and recovery slideway 3 are installed on each set of shelf beams to form a storage warehouse for bagged items; a guide is installed on both ends of the storage slideway 2 Plate 2-1.

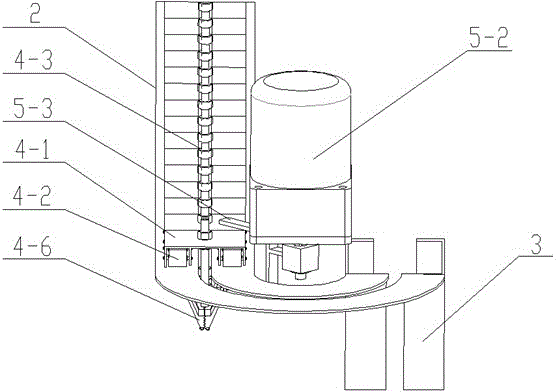

[0041] Tackle 4 is made of skateboard seat 4-1, roller 4-2, suspension shaft 4-3, roller shaft 4-4, guide ...

Embodiment 2

[0047] Embodiment 2, the clip control and driving mechanism of the sorting device are composed of electromagnets, see the attached Figure 7 .

[0048] The sorting device includes an electromagnet 10 fixed on the storage slide 2, and a guide plate 2-1 installed on the armature driven by the electromagnet 10.

[0049] First, the bagged items are manually clamped on the clips 4-6 of the trolley 4, and added into the storage slideway 2 from the rear of the sorting device. Slide to the front end outlet, the clip 4-6 is blocked by the guide plate 2-1 on both sides at the outlet.

[0050] The control system receives the sorting instruction information from the host computer, including the type and quantity of the items. Different items are stored in different slideways, and the electromagnet 2 corresponding to the front end of the slideway is activated to drive the guide plate to move forward. The plate forms an extrusion force on the clip, and the clip is opened. The shift fork 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com