Antimicrobial haemostatic dressing and production method thereof

A production method and a technology for hemostatic dressings, which are applied in the field of wound dressings, can solve the problems affecting the comfort of hydrogel wound dressings, increase the thickness of hydrogel wound dressings, and have no antibacterial properties of hydrogels, so as to promote wound healing, The effect of hemostasis wound healing and prevention of purulent infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Step 1, collagen is dissolved in a solvent to make spinning stock solution

[0046] 10 Collagen was dissolved in hexafluoroisopropanol to prepare a spinning stock solution with a concentration of 7% by weight, which was preserved for future use.

[0047] Step 2, electrospinning followed by crosslinking with glutaraldehyde vapor to prepare collagen fibers

[0048] Under the conditions of voltage 19kV, receiving distance 12cm, flow rate 0.6ml / h, and air humidity 55%, the spinning dope was electrospun.

[0049] 25% concentration of glutaraldehyde vapor was crosslinked in a vacuum desiccator for 18 h, and then vacuum dried for 36 h.

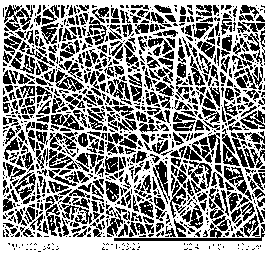

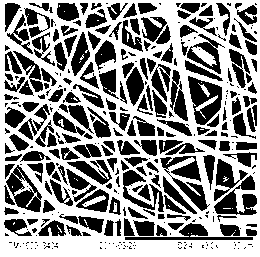

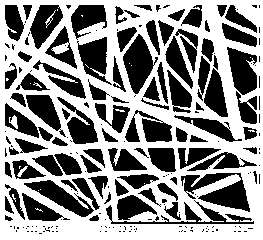

[0050] SEM was magnified 1000 times, 3000 times and 5000 times respectively, and the SEM photos were as follows Figure 1~Figure 3 As shown, the collagen fibers are uniform in thickness, with an average diameter of about 600nm.

[0051] Step 3, Ag 4 o 4 Dissolved in ammonia water, soaked or sprayed onto the collagen fibers prepared in ste...

Embodiment 2

[0054] Step 1, collagen is dissolved in a solvent to make spinning stock solution

[0055] 10g of collagen was dissolved in hexafluoroisopropanol to prepare a spinning stock solution with a concentration of 6% by weight, which was preserved for future use.

[0056] Step 2, electrospinning followed by crosslinking with glutaraldehyde vapor to prepare collagen fibers

[0057] Under the conditions of voltage 21kV, receiving distance 15cm, flow rate 0.6ml / h, and air humidity 50%, the spinning dope was electrospun.

[0058] 25% glutaraldehyde vapor was crosslinked in a vacuum desiccator for 12 h, and then vacuum dried.

[0059] SEM was magnified 1000 times, 3000 times and 5000 times respectively, and the collagen fibers were uniform in thickness, with an average diameter of about 550nm.

[0060] Step 3, Ag 4 o 4 Dissolved in ammonia water, soaked or sprayed onto the collagen fibers prepared in step 2, and dried to obtain an antibacterial hemostatic dressing

[0061] 0.05g Ag ...

Embodiment 3

[0068] Step 1, collagen is dissolved in a solvent to make spinning stock solution

[0069] Dissolve 10 g of collagen in hexafluoroisopropanol to prepare a spinning stock solution with a concentration of 5% by weight, and store it for future use.

[0070] Step 2, electrospinning followed by crosslinking with glutaraldehyde vapor to prepare collagen fibers

[0071] Under the conditions of voltage 38kV, receiving distance 15cm, flow rate 0.02ml / h, and air humidity 50%, the spinning dope was electrospun.

[0072] 25% glutaraldehyde vapor was crosslinked in a vacuum desiccator for 12 h, and then vacuum dried.

[0073] SEM was magnified 1000 times, 3000 times and 5000 times respectively, and the collagen fibers were uniform in thickness, with an average diameter of about 650nm.

[0074] Step 3, Ag 4 o 4 Dissolved in ammonia water, soaked or sprayed onto the collagen fibers prepared in step 2, and dried to obtain an antibacterial hemostatic dressing

[0075] 0.05g Ag 4 o 4 Sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com