Flue gas purification tower nozzle

A technology for flue gas purification towers and nozzles, applied in the direction of injection devices, injection devices, etc., can solve the problems of reducing purification efficiency, increasing labor costs and time, and achieve the effect of unobstructed channels and reduced clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

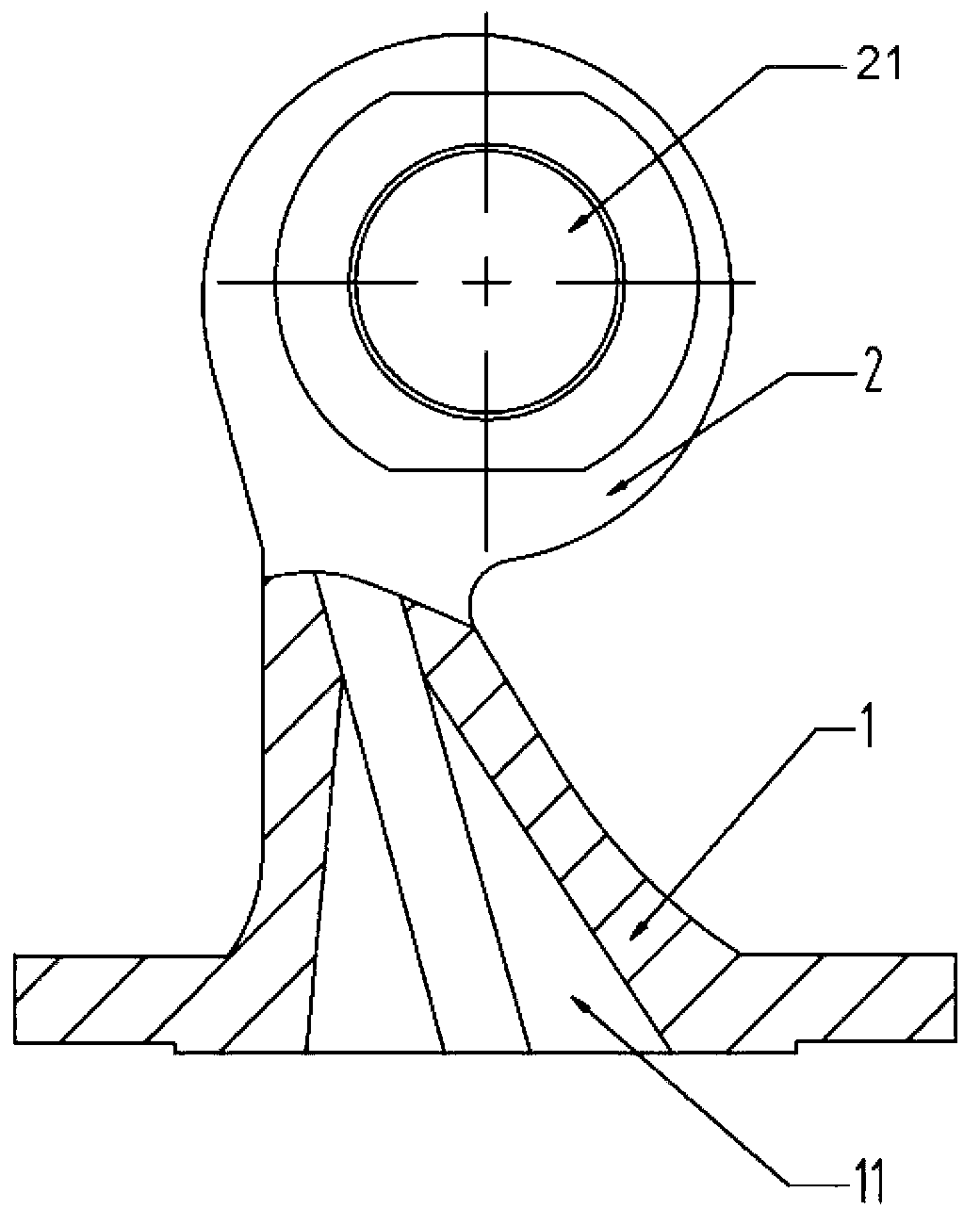

[0014] Such as figure 1 and figure 2 , this embodiment provides a flue gas purification tower nozzle, including a base 1, and also includes a nozzle body 2 with an integral structure with the base 1, a cavity 11 is provided on the base 1, the nozzle body 2 is a hollow structure, and the base 1 The cavity 11 communicates with the cavity inside the nozzle body 2, and the two ends of the nozzle body 2 are provided with nozzles 21. The inner wall of the nozzle 21 is conical, and the cone angle of the inner wall of the nozzle 21 is 90 degrees. The nozzle 21 has a diameter of 90 mm.

[0015] The spray shape of the spray area is hollow cone. The unique design structure of the nozzle can make the outlet water volume of the nozzle with small flow rate reach a liquid flow section several times larger than that of ordinary nozzles. There is no inner core structure, and the channel of the nozzle is more smooth, minimizing There is no special requirement for the water quality of the wat...

Embodiment 2

[0017] Such as image 3 As shown, this embodiment provides a flue gas purification tower nozzle, which includes a base 1 and a nozzle body 2 integrated with the base 1. The base 1 is provided with a cavity 11, and the nozzle body 2 is a hollow structure. The cavity 11 of the base 1 communicates with the cavity inside the nozzle body 2, and the two ends of the nozzle body 2 are provided with nozzles 21. The inner wall of the nozzle 21 is conical, and the cone angle of the inner wall of the nozzle 21 is 90 degrees. The nozzle 21 has a diameter of 90 mm. The nozzle body 2 is provided with a core 3, the core 3 includes a connection part 31 and an extension part 32, the connection part 31 is fixedly connected with the nozzle body 2, the extension part 32 extends out of the nozzle body 2, and is adapted to the nozzle 21, The protruding portion 32 is tapered, and there is a gap between the protruding portion 32 and the inner wall of the spray head 21 . The gap between the protrudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com