Elevator lifting car bracket

An elevator car and beam technology, which is applied to elevators in buildings, non-rotational vibration suppression, transportation and packaging, etc., can solve problems such as complex structure, and achieve the effect of simplifying car structure, structure and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

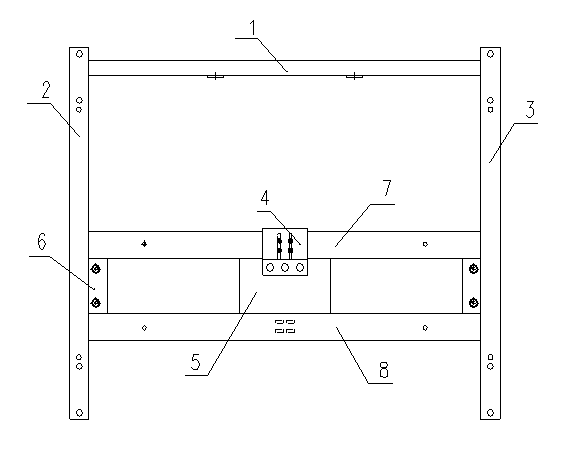

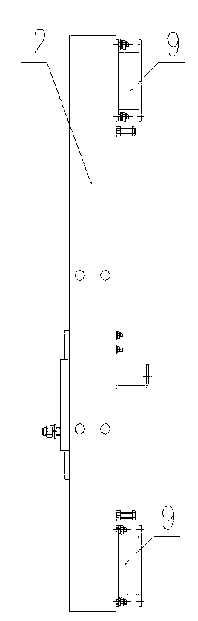

[0014] Such as figure 1 , figure 2 As shown, an elevator car bracket includes a back beam 1, a left beam 2, a right beam 3, a weighing device 4, a buffer strike plate 5, a safety gear mounting plate 6, a first beam 7, a second beam 8, a Vibration device 9, the upper end of left beam 2, right beam 3 is respectively connected with the two ends of rear beam 1, and the middle part of left beam 2, right beam 3 is respectively provided with up and down parallel first crossbeam 7, second crossbeam 8, is positioned at the first A weighing device 4 is arranged on the beam 7, a buffer strike plate 5 is arranged between the weighing device 4 and the second beam 8 located at the lower part, and at least two sets of safety gear mounting plates 6 are arranged between the first beam 7 and the second beam 8; At least two groups of damping devices 9 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com