Mechanical automobile tire burst support device

A support device and mechanical technology, applied in vehicle parts, tire parts, transportation and packaging, etc., can solve problems such as troublesome disassembly, poor comfort of run-flat tires, etc., and achieve the effects of low price, obvious emergency effect and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

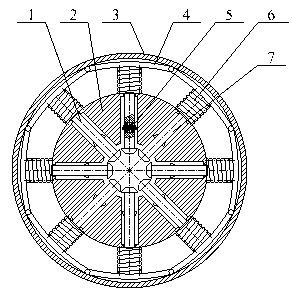

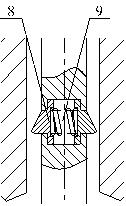

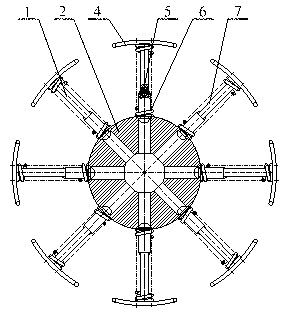

[0020] Such as figure 1 As shown in the front view, the telescopic assembly 1 is composed of the hub segment 4, the support claw 5, the spring 6 and the support rod 7. The number of the telescopic assembly 1 can be changed into six groups, eight groups, or ten groups according to the load-bearing capacity of different vehicles and the size of the tires. group, twelve groups, etc., the hub segment 4 is a circular arc, one end of the support rod 7 is welded to the middle of the hub segment 4, the other end of the 7 is inserted into the guide groove of the housing 2, and the supporting claws 5 are formed by a pair of claws 8 Formed with elongation spring 9, the support claw 5 is installed in the middle position of the support rod 7 inserted into the guide groove part, and the spring 6 is sleeved on the periphery of the support rod 7 protruding from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com