Mechanical-rotary-plate-type fully-automatic gilding press

A fully automatic hot stamping machine and turntable technology, which is applied to printing machines, gold powder printing, rotary printing machines, etc., can solve the problems of reducing work efficiency, safety factor, and increasing labor intensity, and achieves high work efficiency, good effect, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

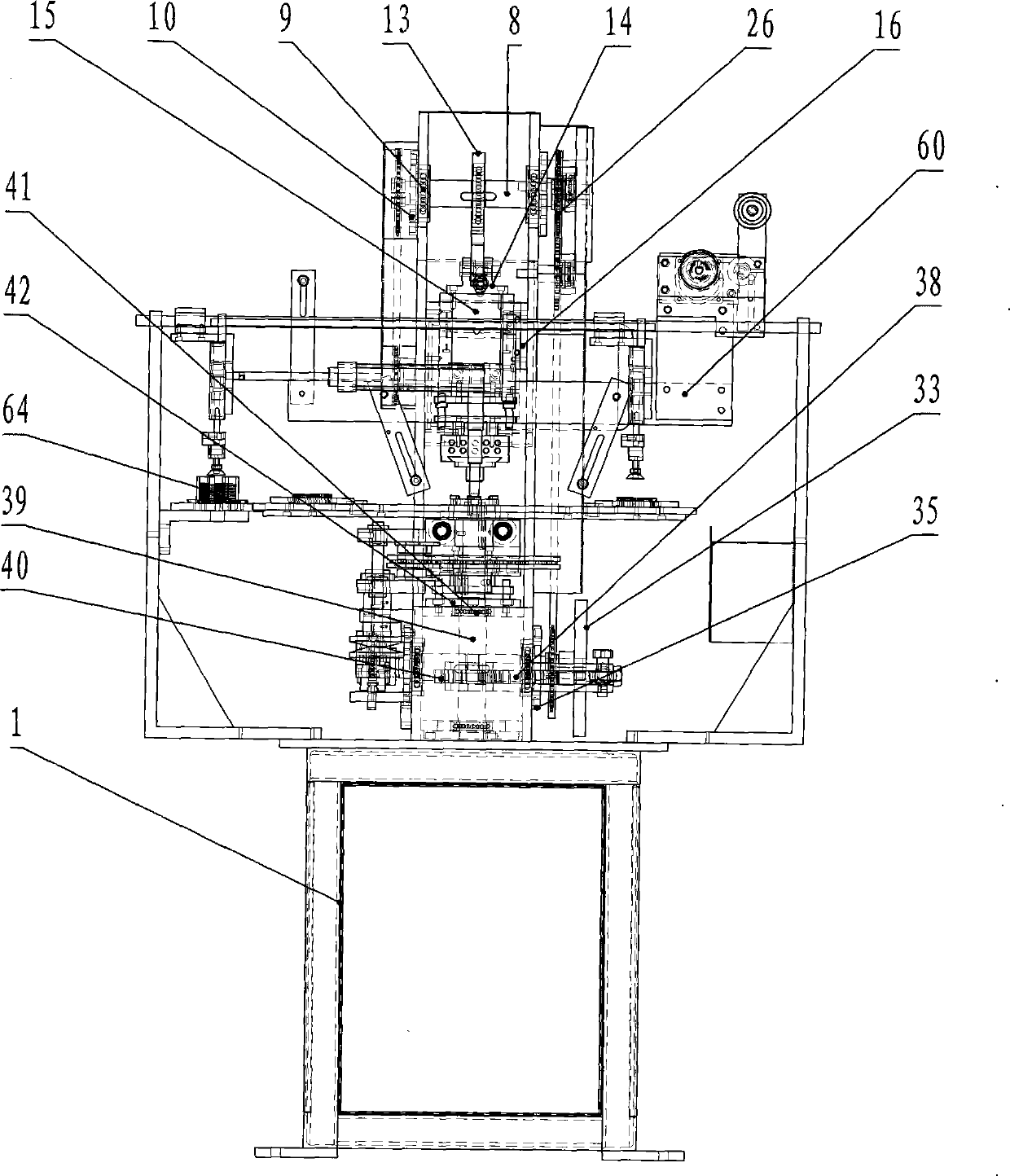

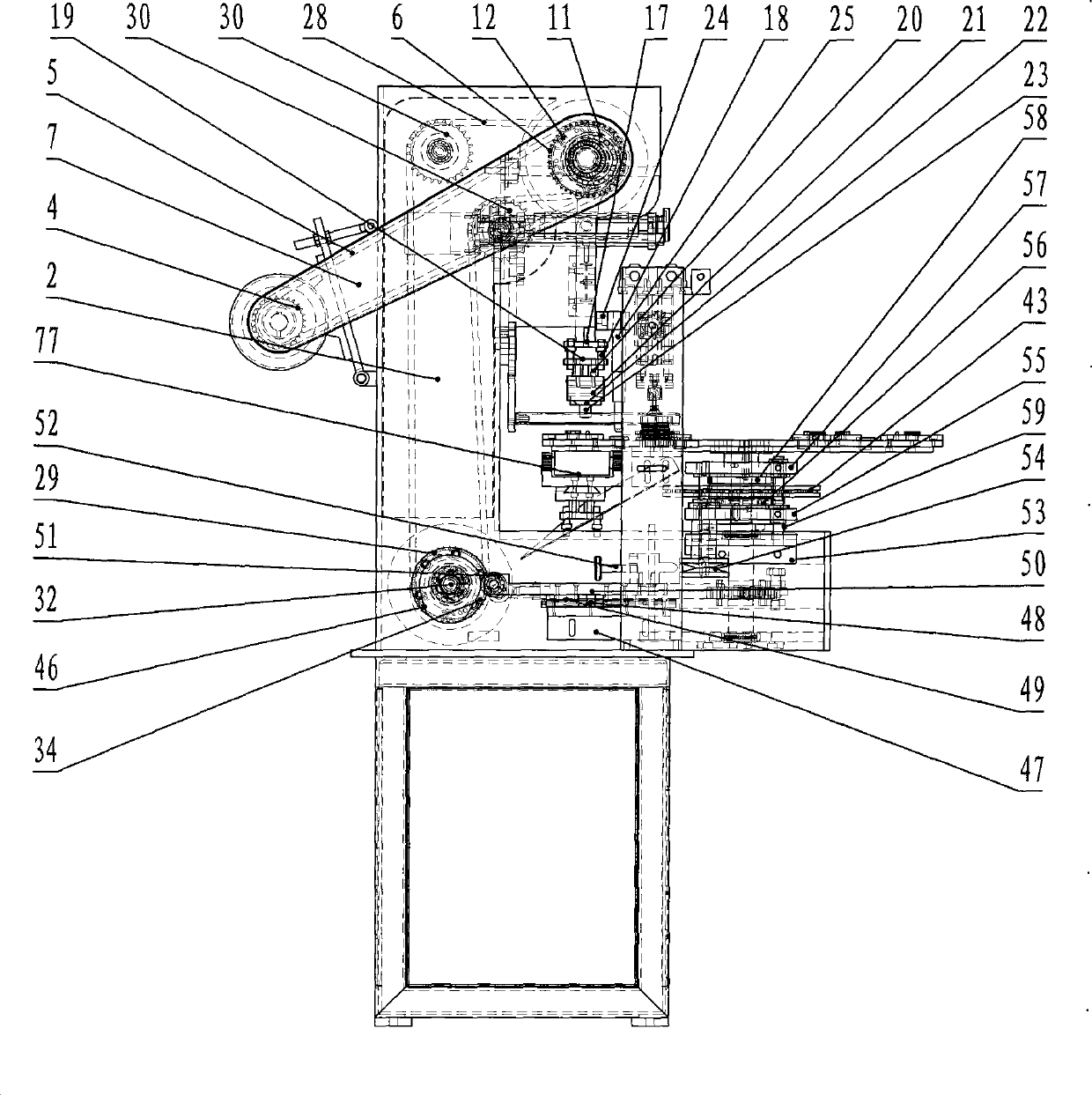

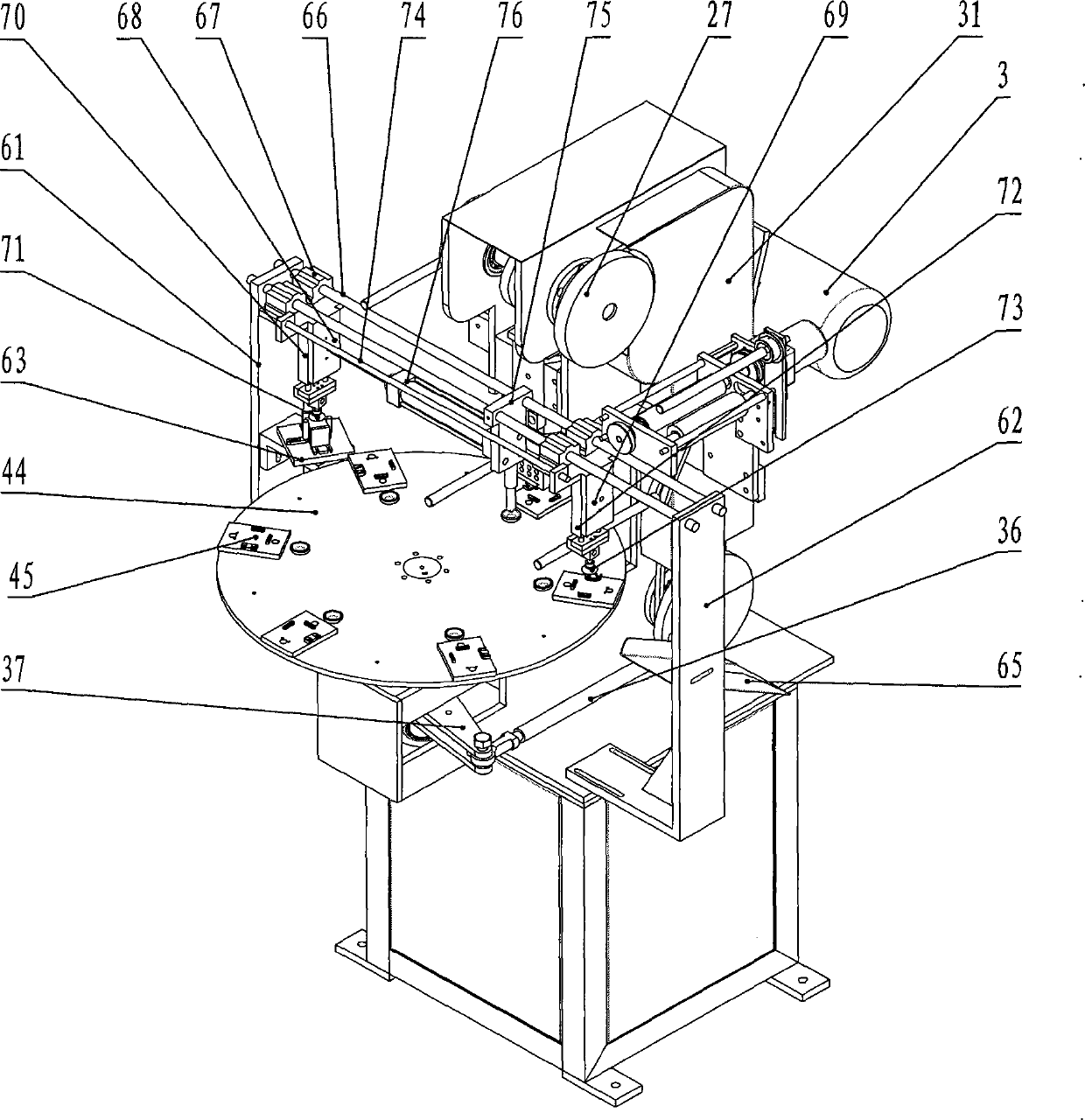

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012]As shown in the figure, a mechanical turntable type automatic hot stamping machine includes a base 1 and a main machine 2. Its characteristics are: a main machine 2 is installed on the top of the base 1, and a main power motor 3 is installed on the back of the main machine 2, and the main power motor 3 outputs Drive sprocket 4 is housed on the axle, and drive chain 5 is housed on drive sprocket 4, and drive drive chain 5 connects 41 tooth sprocket A6, and motor chain shield 7 is housed on drive sprocket 4 and 41 tooth sprocket A6, The 41-tooth sprocket A6 is installed on the main shaft 8, and two 6207 bearings 9 are installed on the main shaft 8. The eccentric wheel 11 is installed in the middle of 8, the eccentric wheel 11 is installed in the 6012 bearing 12, the 6012 bearing 12 is installed in the eccentric wheel outer cover 13, the eccentric wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com