Double-layer floating vibrating sieve

A double-layer, sieve box technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of affecting screening efficiency and blocking holes, and achieve the effects of improving screening efficiency, saving energy, and preventing hole blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

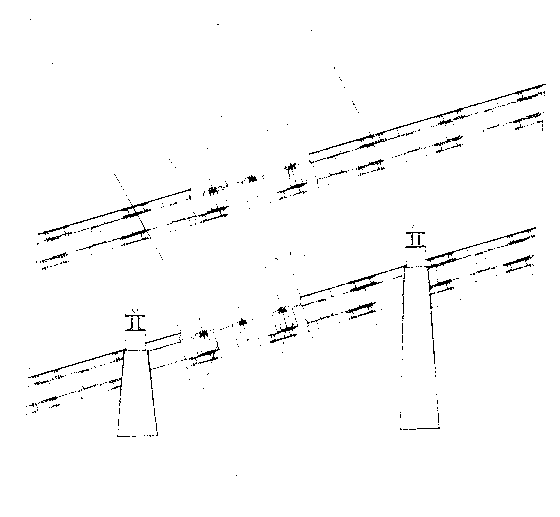

[0008] The embodiment is described in detail in conjunction with the accompanying drawings. It is installed in a screen box 1 with two layers of sieve plates, an upper resonant body 3 is installed under the upper sieve plate 2, and a lower resonant body is installed under the lower sieve plate 5. 6. The installation method of each layer of sieve plates is that one end is fixed on the screen box, and the other end is fixed on the resonator, and elastic parts 4 are evenly distributed between the upper and lower sieve plates and the upper and lower resonators. When working, there is a relative displacement gap between the screen box and the two layers of sieve plates, so that the two layers of sieve plates can bend and stretch while vibrating with the screen box, which can double the local vibration intensity of each sieve plate, effectively Improve screening efficiency, especially suitable for screening high-humidity viscous substances.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com