Top net forming machine capable of adjusting two-side difference of paper

A former and top wire technology, which is applied in the field of pulp and paper making, can solve the problem of not being able to independently adjust the dehydration amount of the wet paper sheet up and down, and the difference between the two sides of the paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

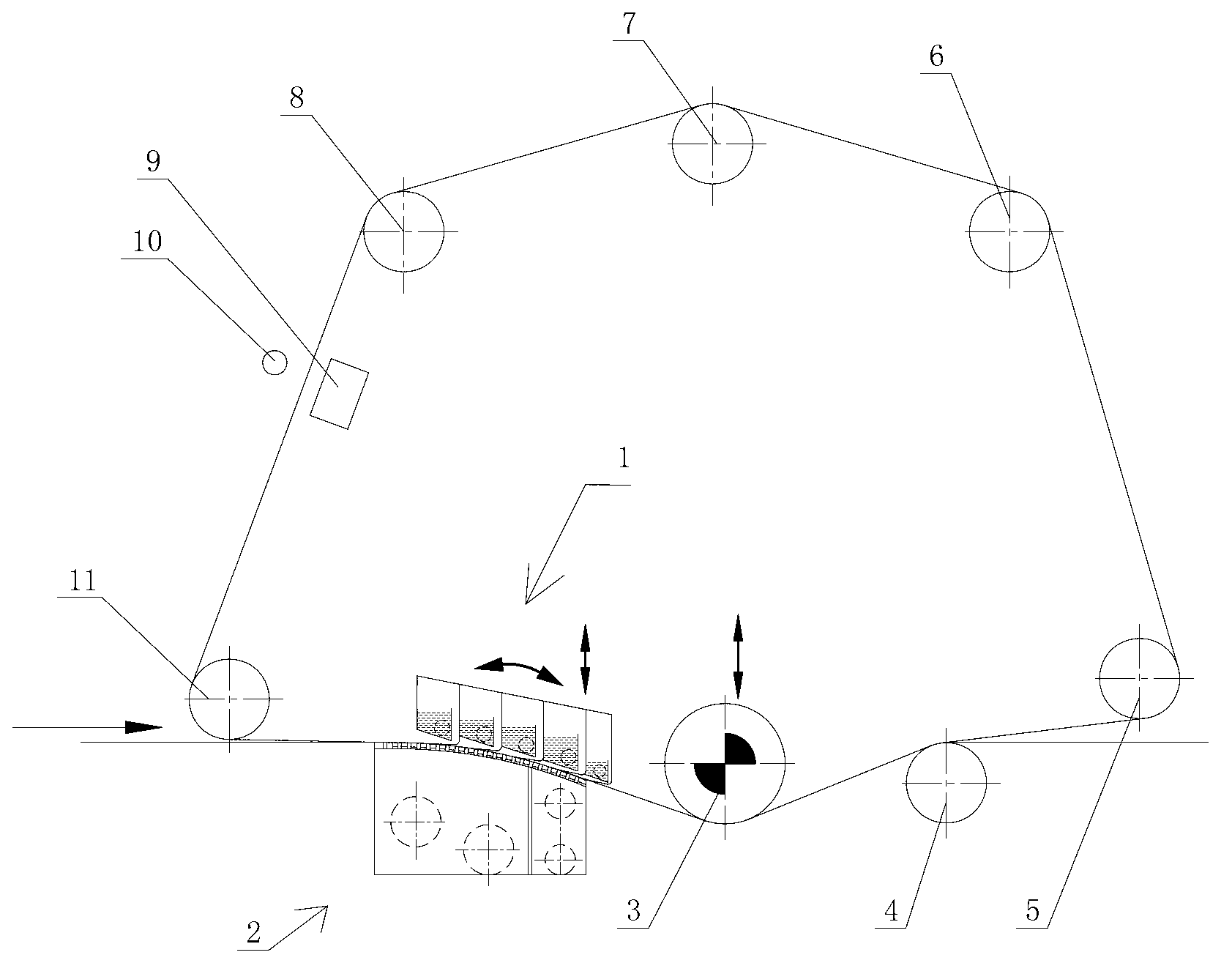

[0027] Such as figure 1 shown. The top wire former capable of adjusting the difference between the two sides of the paper includes forming rollers 3, vacuum suction rollers 4, lead-out rollers 5, return rollers 6, mesh correction rollers 7, tension rollers 8, mist suction boxes 9, and high-pressure water spray pipes 10. Lead-in roller 11, top wire suction box 1 and bottom wire suction box 2 correspondingly arranged below the top wire suction box 1, the paper is clamped on the lower surface of the top wire suction box 1 and the upper surface of the bottom wire suction box 2 between.

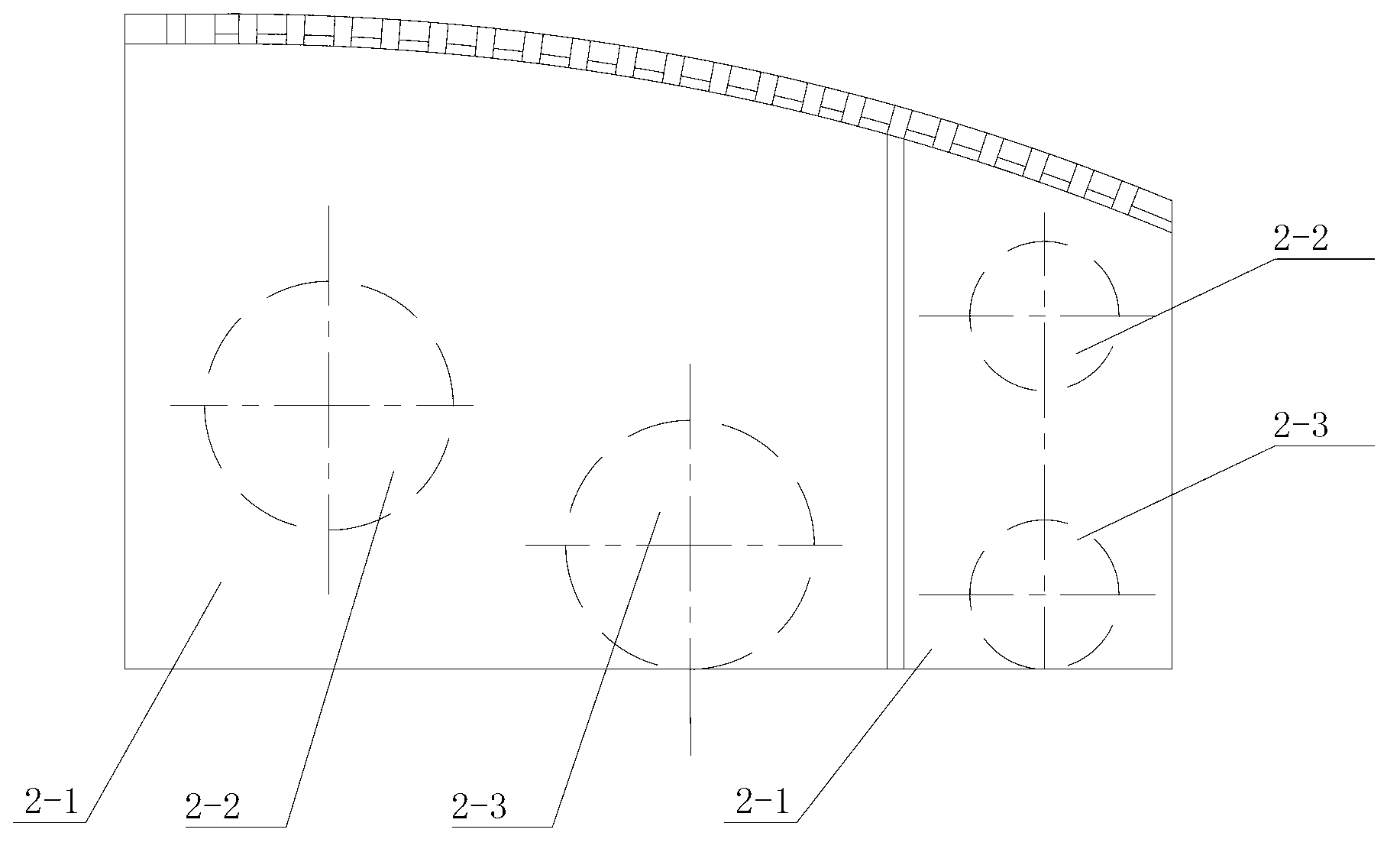

[0028] Such as figure 2 shown. The top net water suction box 1 is composed of a plurality of top net water absorption areas 1-1 arranged in sequence along the paper advancing direction, and each top net water absorption area 1-1 includes, arranged on the lower surface of the top net water suction box 1 for Scraper 1-3 for scraping the moisture on the upper surface of the paper, water baffle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com