A three-way anammox bioreactor

A bioreactor, anammox technology, applied in the field of ternary anammox bioreactor, can solve the problems of poor separation effect of mud and water, difficult to collect, lost sludge, etc., to solve the problem of sludge loss and speed up the process start effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

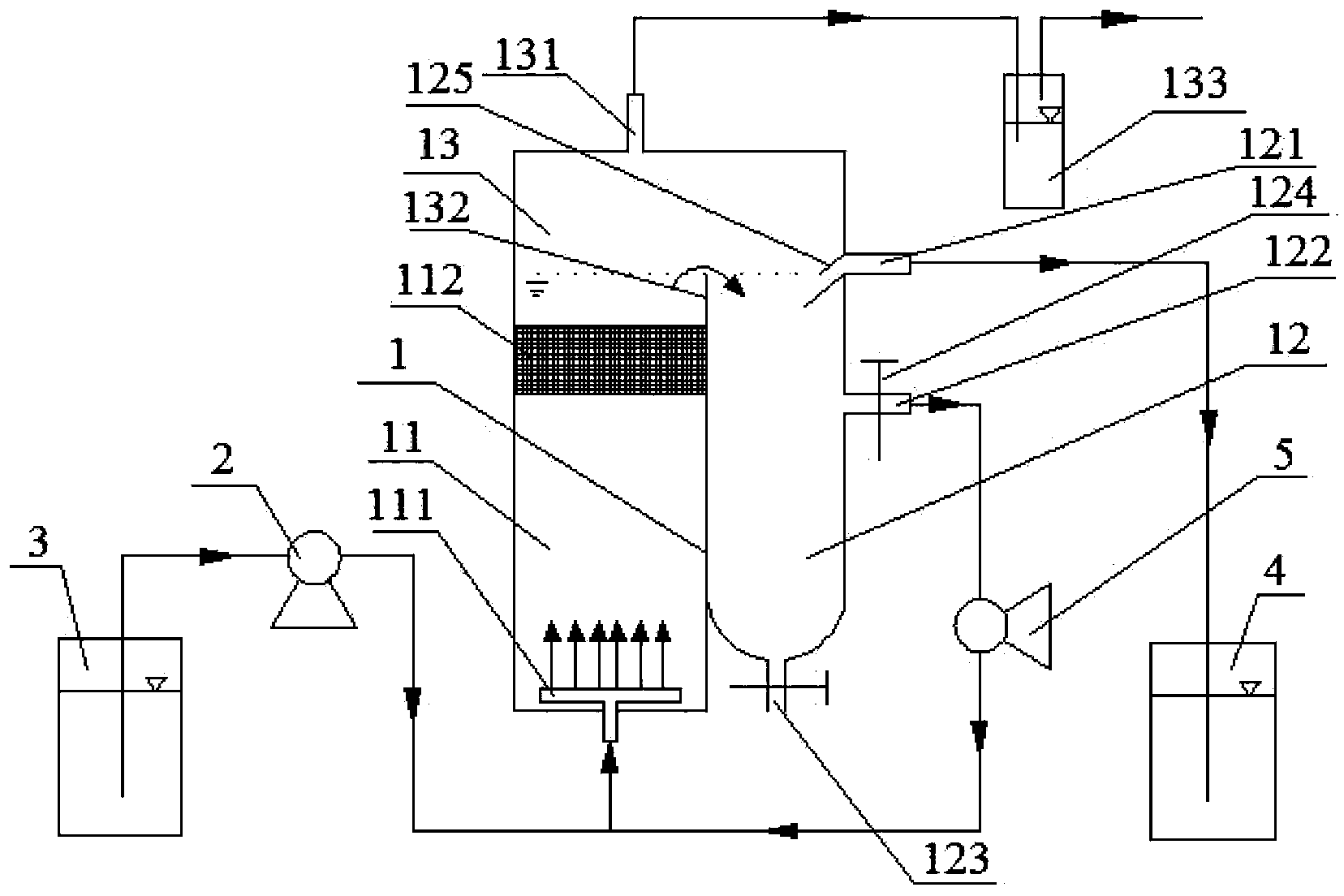

[0013] Further illustrate the present invention below in conjunction with accompanying drawing

[0014] Referring to the attached picture:

[0015] A three-way anammox bioreactor according to the present invention includes a reactor vessel 1, and the reactor vessel 1 includes a biological reaction unit 11, a sludge recovery unit 12 and a three-phase separation unit 13; The lower end of the biological reaction unit 11 is provided with a water inlet 111, and the inner cavity of the biological reaction unit 11 is equipped with a porous partition 112; the sludge recovery unit 12 is sequentially provided with a water outlet 121, a return port 122 and The mud discharge port 123, the water outlet 121 is provided with two parallel sloping plates 125 with the ends facing down, the return port 122 and the mud discharge port 123 are respectively provided with control valves 124; the three The phase separation unit 13 is located above the biological reaction unit 11 and the sludge recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com