Dust collecting hopper

A dust hopper and bucket body technology, applied in the field of dust hoppers, can solve the problems of a large amount of dust, waste, and large application limitations, and achieve the effects of uniform bulk materials, improving loading efficiency, and reducing dust and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

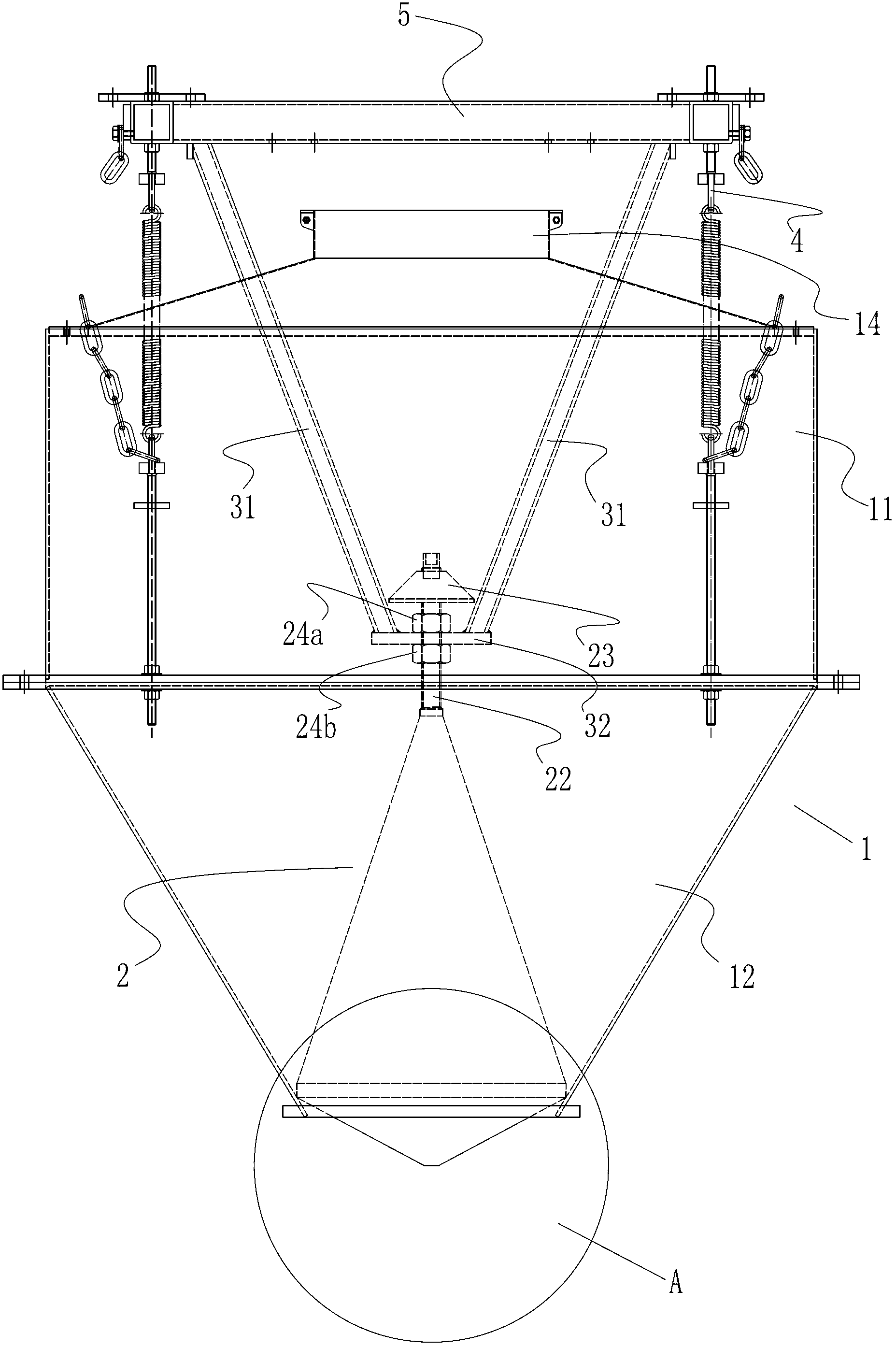

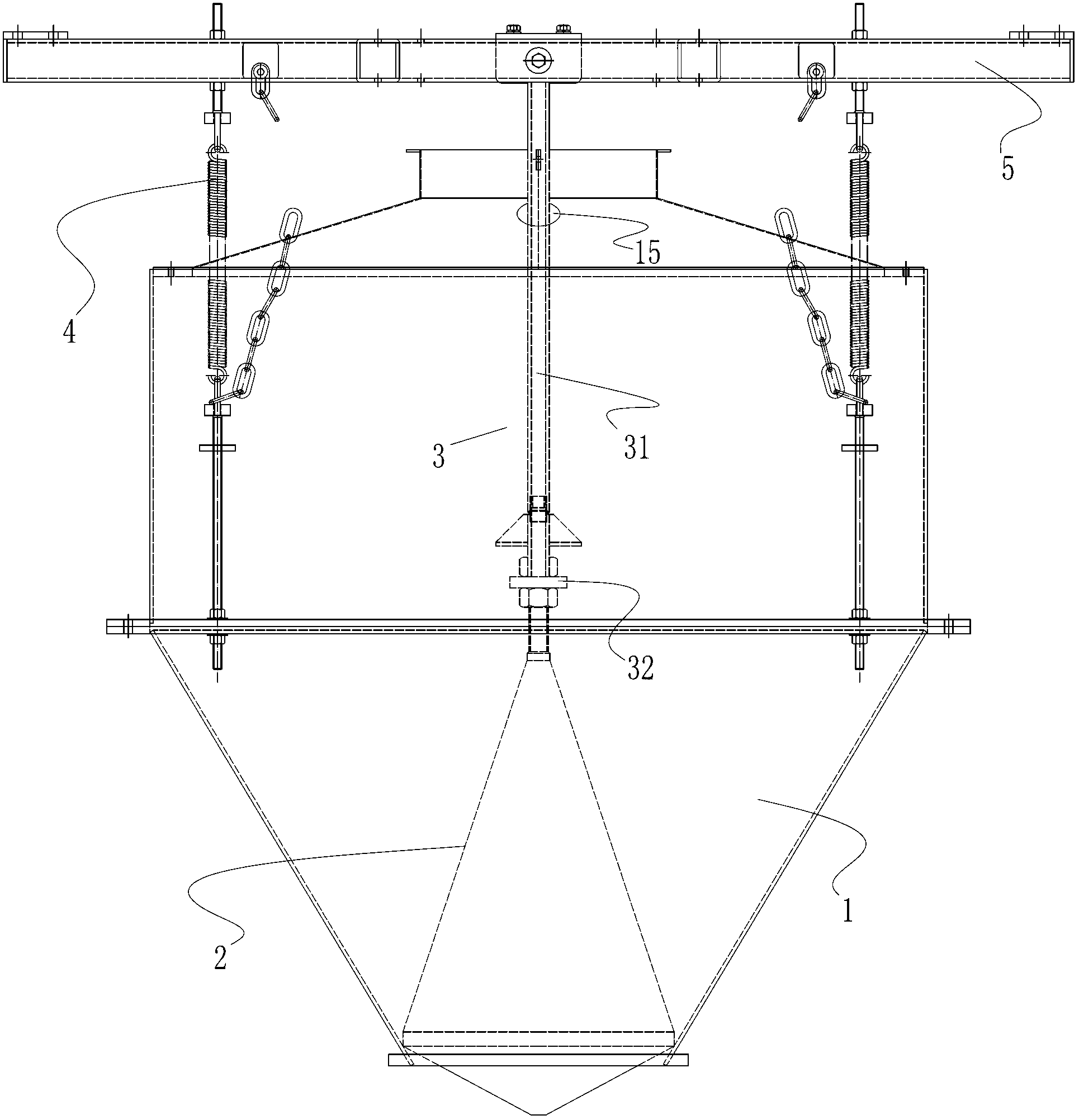

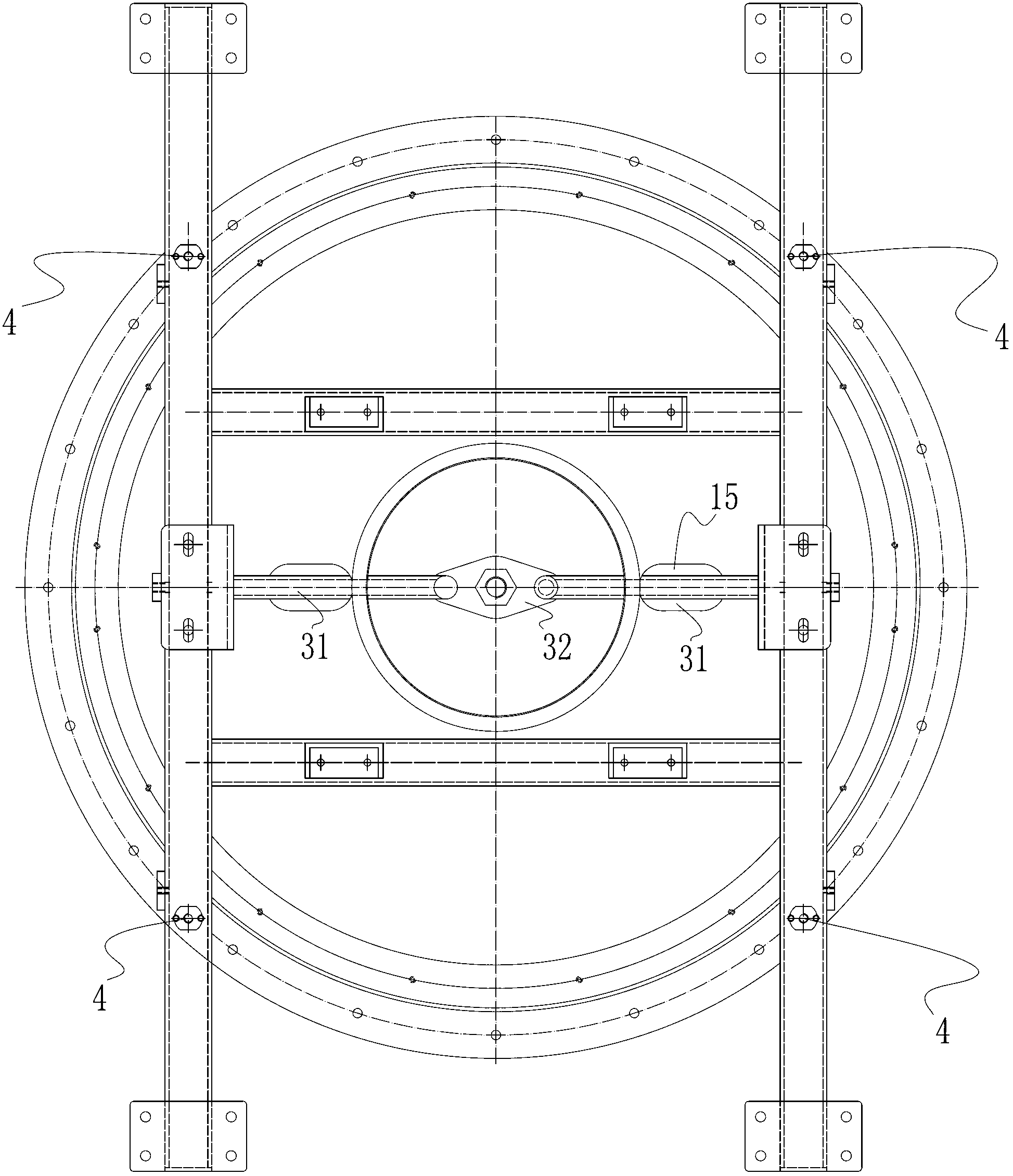

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as Figures 1 to 4 As shown, the dust collection hopper of the present invention includes a bucket body 1 and a plug 2, and the bucket body 1 is hung on the support 5 in a liftable manner by, for example, four symmetrically arranged elastic connecting rods 4. The upper part of the bucket body 1 has The inlet for materials to enter, the lower part 12 of the bucket body 1 is in the shape of a funnel, and the bottom of the lower part 12 has a discharge opening 121 . Plug 2 is fixedly installed on the support 5, and is positioned at the inside of bucket body 1, and plug 2 includes such as Figure 4 The valve part 212 shown, the upper guide part 211 and the lower guide part 213 respectively connected with the valve part 212 at the upper and lower sides, the diameter of the valve part 121 is greater than the diameter of the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com