Liquid filling method for soft bag infusion products

A soft bag infusion, liquid medicine technology, applied in the directions of transportation and packaging, transportation and packaging, packaging, etc., can solve the problems of difficult operation, leakage, reduce the sealing strength of the filling mouth, etc., and overcome the pollution of the side wall of the filling mouth. , Reliable heat sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Further illustrate the present invention below in conjunction with accompanying drawing.

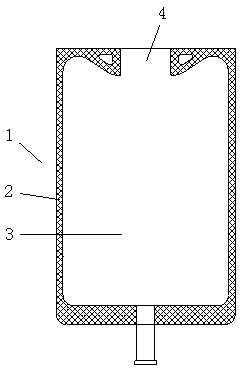

[0037] The liquid medicine filling method of the soft bag infusion product of the present invention uses the prepared soft bag as the packaging container, and the soft bag is as follows: Figure 1a As shown in , the soft bag 1 is provided with a liquid cavity 3 surrounded by the sealing edge 2, and the liquid cavity 3 is provided with a filling port 4 formed by a reserved unsealed gap. see figure 2 , before filling the liquid medicine, the two side walls of the liquid chamber 3 of the soft bag are stuck together and are in a sheet shape.

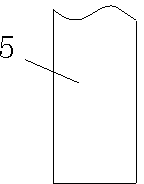

[0038] The filling method of the present invention utilizes the filling head to fill the liquid medicine in the liquid chamber of the soft bag, and the structure of the filling head 5 is as follows: Figure 1b , Figure 1c Shown as flat mouth.

[0039] The process of filling the liquid medicine in the liquid cavity 3 of the soft bag 1 with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com