Torque automatic control system for electric screwdriver

An electric screwdriver, automatic control system technology, applied in screwdrivers, wrenches, manufacturing tools, etc., can solve the problems of inaccurate torque setting, lag, uncontrollable torque overload, etc., to avoid too loose or too tight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

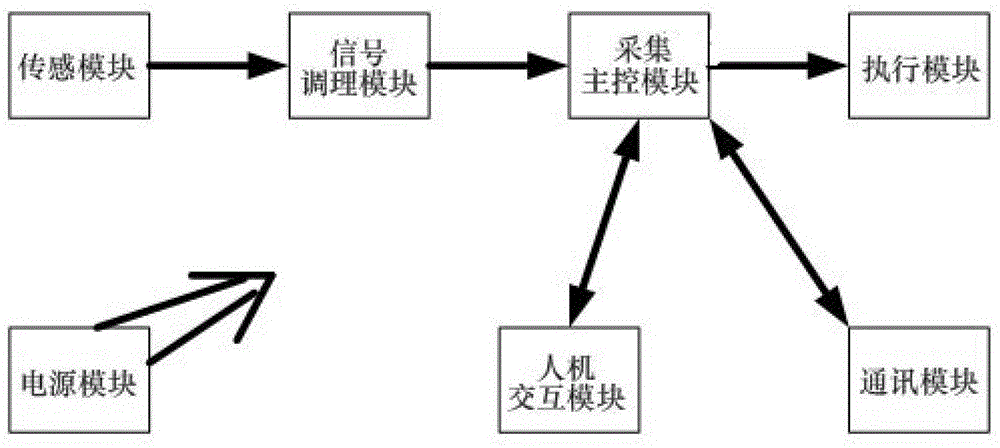

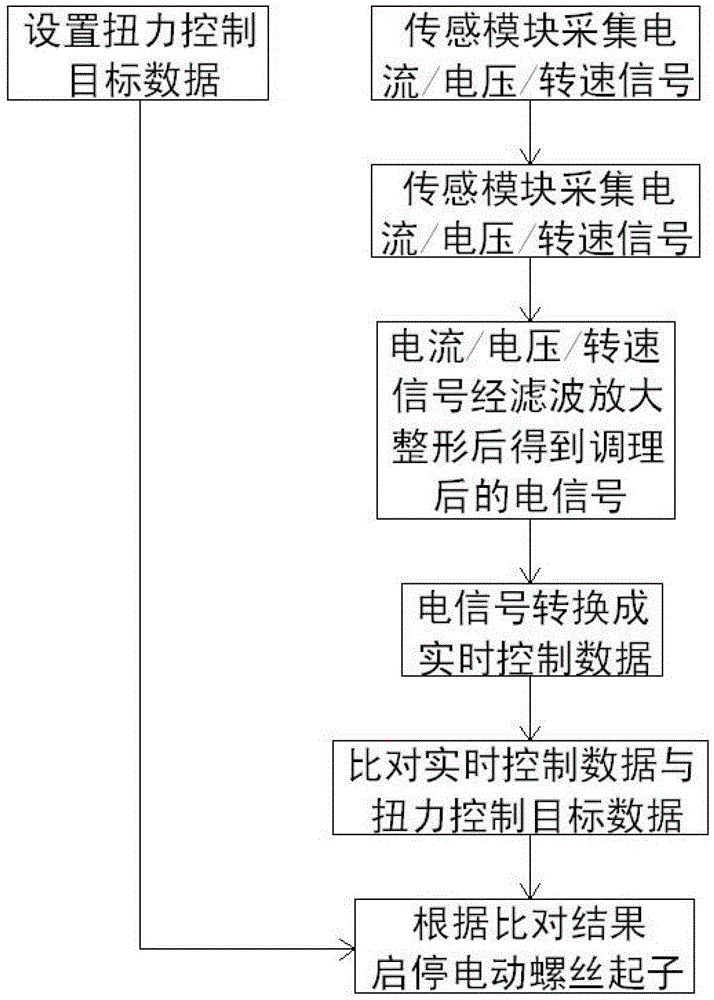

[0021] This embodiment describes a torque automatic control system for electric screwdrivers, the system structure block diagram is as follows figure 1 As shown, the torque automatic control system includes a sensing module, a signal conditioning module, an acquisition main control module and an execution module that drives the electric screwdriver body connected in sequence,

[0022] The sensing module senses the current, voltage, and speed signals of the screwdriver in real time, and transmits the collected current, voltage, and speed signals to the signal conditioning module;

[0023] The signal conditioning module converts the received current, voltage and speed signals into electrical signals suitable for A / D acquisition and processing through filter circuits, amplifier circuits, and shaping circuits, and transmits the conditioned electrical signals to the acquisition master through electronic circuits module;

[0024] The acquisition main control module collects the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com