Spark plug

一种火花塞、电阻值的技术,应用在火花塞领域,能够解决火花塞跳火性能下降、点火能量减少等问题,达到电波杂音的水平减少、抑制跳火性能下降的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

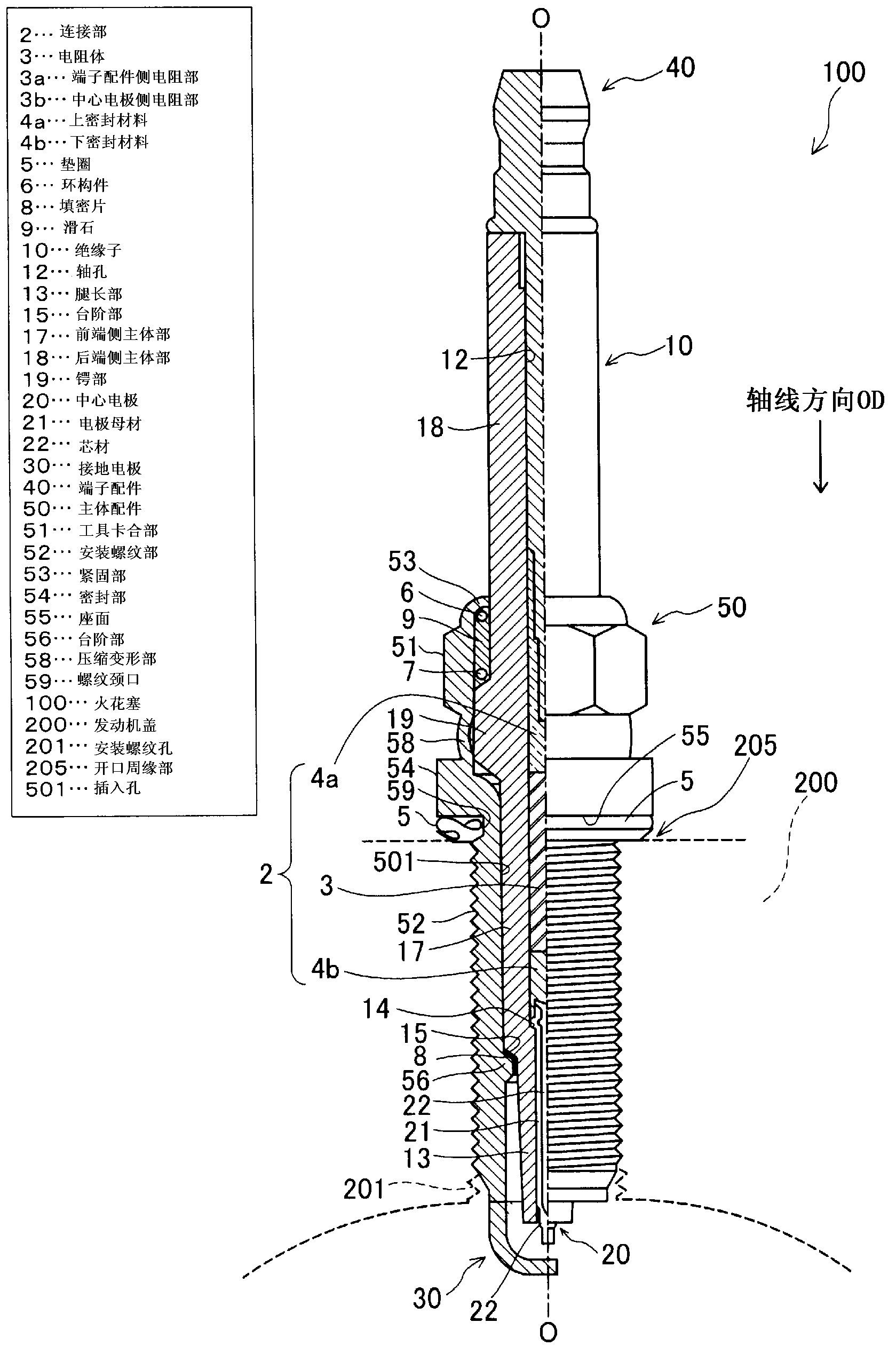

[0032] figure 1 It is a partial cross-sectional view of a spark plug 100 as an embodiment of the present invention. in figure 1 Here, the right side of the axis O-O indicated by the dashed-dotted line represents a front view of the appearance, and the left side of the axis O-O represents a cross-sectional view obtained by cutting the spark plug 100 with a cross section passing through the central axis of the spark plug 100. Below, will figure 1 The lower side of the spark plug 100 in the axial direction OD is the tip side of the spark plug 100, and figure 1 The upper side in the axial direction OD of the spark plug 100 in FIG. 1 is described as the rear end side.

[0033] The spark plug 100 includes an insulator 10 as an insulator, a metal shell 50, a center electrode 20, a ground electrode 30, and a terminal fitting 40. The metallic shell 50 has an insertion hole 501 penetrating in the axial direction OD. The insulator 10 is inserted into the insertion hole 501 and held. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com