Self-adaptation sealing-type mechanical sealing device

A mechanical sealing device and self-adaptive sealing technology, applied in mechanical equipment, engine sealing, engine components, etc., can solve problems such as the wear of the end face slope angle, the sealing parameters do not match the design, and the normal operation of the sealing cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

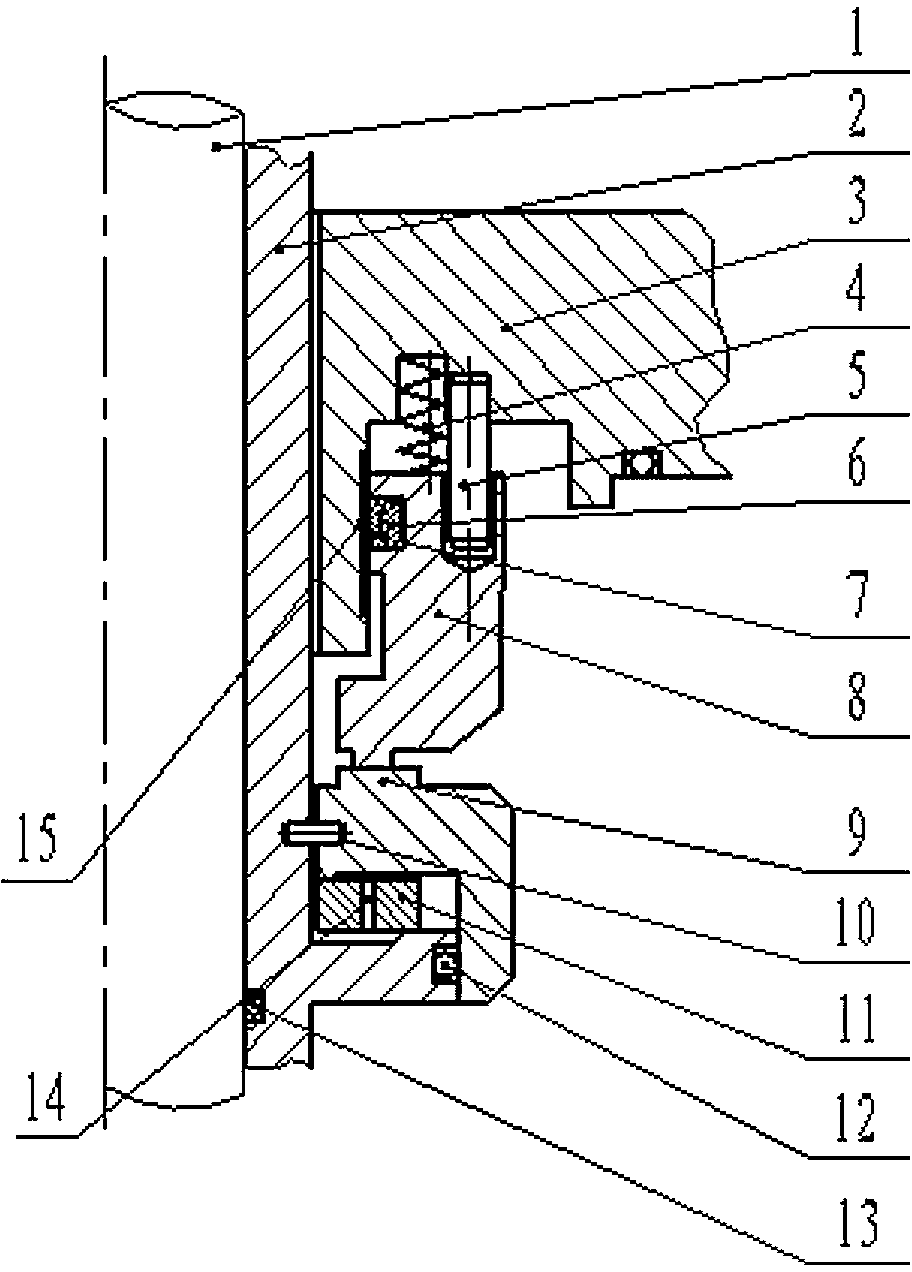

[0014] figure 1 Shown is the basic structure of the mechanical seal device of the self-adaptive sealing type of the present invention. It is connected with the rotating shaft 1 and is equipped with a conventional O-ring seal 13 on the outer side of the shaft sleeve 2, opposite to each other in the axial direction. There are a stationary sealing ring 8 and a rotating sealing ring 9, the opposite axial end faces are sealing surfaces, and the stationary sealing ring 8 is positioned by anti-rotation structures 5 such as anti-rotation pins and a number of springs 4 equidistantly arranged along the circumference. It is arranged on the fixed structure 3 of the sealing end cover; the rotating sealing ring 9 is connected to the rotating shaft sleeve 2 through the transmission structure 10 in the form of a transmission pin, and an O-ring sealing ring 12 is provided on its mating surface. Between the rotary sealing ring 9 and the shaft sleeve 2, an elastic structure 11 in the form of an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com