Method for measuring nozzle vent length of aircraft engine

An aero-engine, length measurement technology, applied in mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve the problems of easy to miss detection, existence of detection errors, low detection efficiency, etc. The effect of reducing detection errors and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1, measuring the nozzle length of a certain type of aircraft engine nozzle.

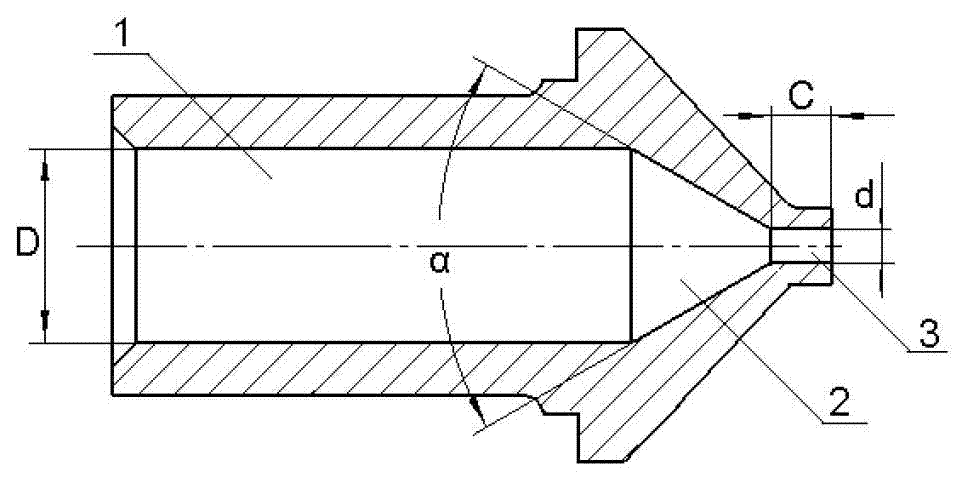

[0015] The hole diameter of the cylindrical section hole 1 of the nozzle is D=4.8mm, the cone angle of the circular platform section hole 2 is α=60, the hole diameter of the small-diameter cylindrical section hole 3 is d=0.8mm, and the specified length of the small-diameter cylindrical section hole 3 is C= 1.5mm; the steps to measure the nozzle length are as follows:

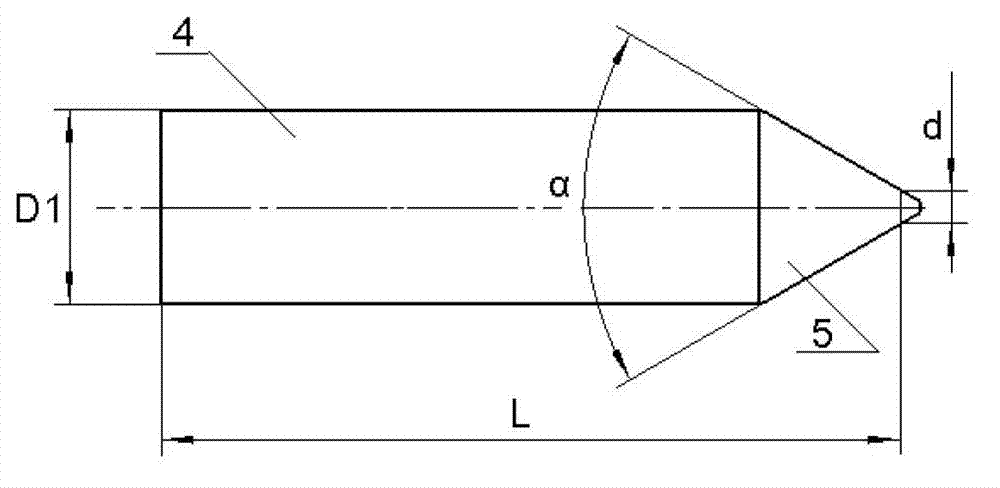

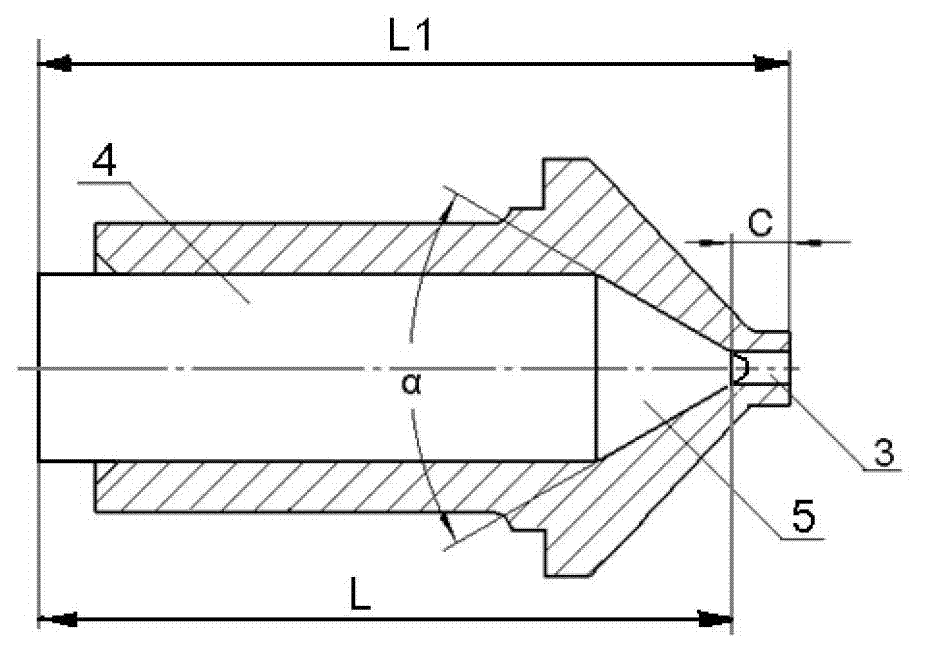

[0016] 1. Manufacture the measuring rod: the outer diameter D1 of the cylindrical shaft 4 of the measuring rod is 4.775mm, and the fit gap with the cylindrical section hole 1 of the inner hole of the nozzle is 0.025mm, and the length of the cylindrical shaft 4 is 5mm longer than the length of the cylindrical section hole 1 of the inner hole of the nozzle. , the cone angle of the cone 5 is α=60, the distance from the left end surface of the measuring rod to the positioning section on the cone 5 is a constant L=40mm, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com