Methods and systems for fuel vapor control

一种燃料蒸气、燃料系统的技术,应用在装料系统、燃料的热处理装置、燃料喷射装置等方向,能够解决燃料蒸气不充分冲洗、烃排放物增加、不充分冲洗等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

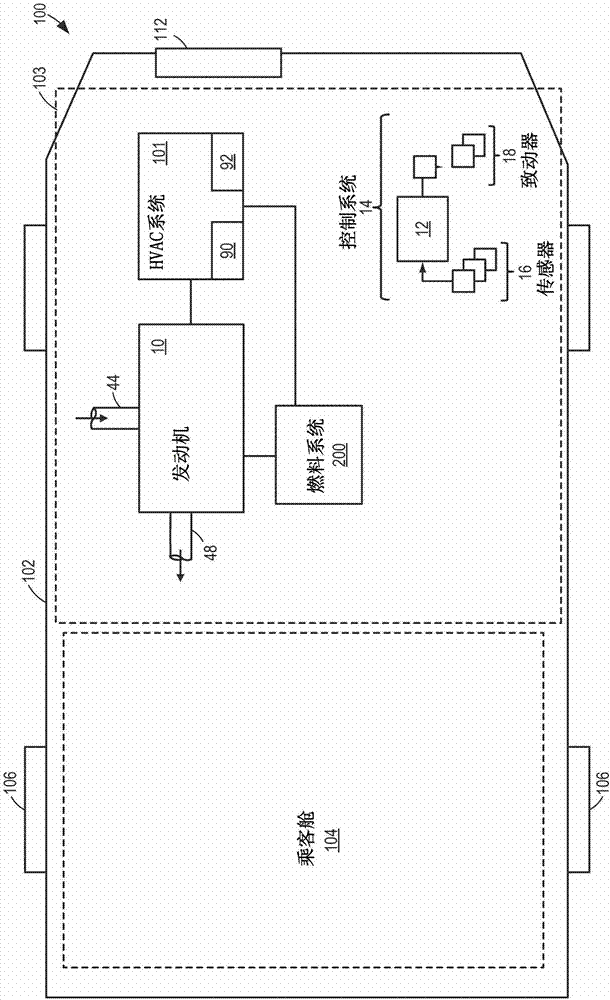

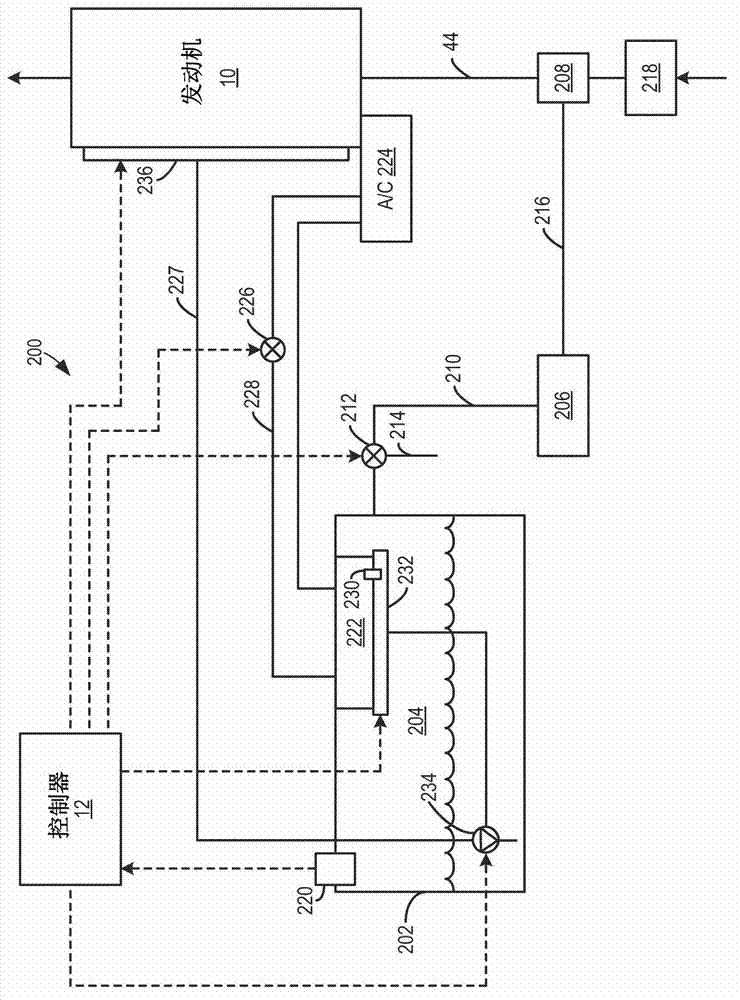

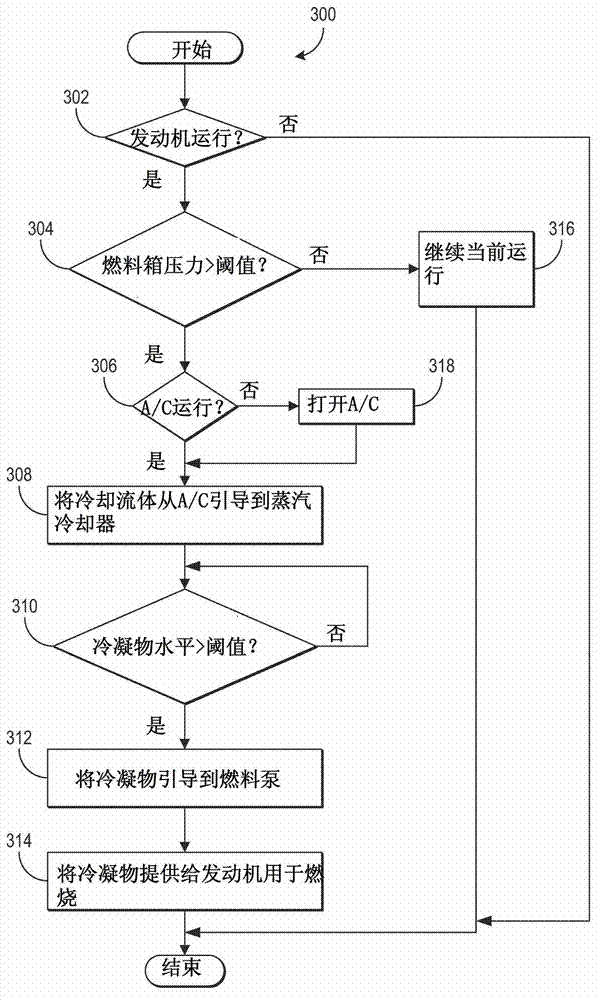

[0022] The following description relates to various embodiments of methods and systems for controlling the pressure in a fuel tank. In an example, a method for a fuel system includes, in response to operating conditions, condensing fuel vapor in an oil vapor cooler provided in the fuel tank, and delivering the condensed fuel vapor to a fuel pump or the fuel The pressurized fuel line between the pump and the nozzle. For example, the vapor cooler may be fluidly connected to the cooling system so that heat exchange can occur between the fuel vapor in the fuel tank and the cooling fluid circulating through the vapor cooler. In this way, the fuel vapor in the fuel tank can be condensed, so that, for example, at a relatively high ambient temperature, the pressure in the fuel tank can be reduced when the pressure of the fuel tank is high. Moreover, in another embodiment, the cooling system operation can be adjusted according to the fuel tank. Various examples will be described in de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com