Formation pressure determination method under condition of failure in wall shut-in during blowout

A formation pressure and determination method technology, applied in wellbore/well components, earthwork drilling, measurement, etc., can solve the problem of indeterminate formation pressure, standpipe pressure that cannot reflect the bottom hole pressure, and casing pressure that cannot be read, etc. problem, to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

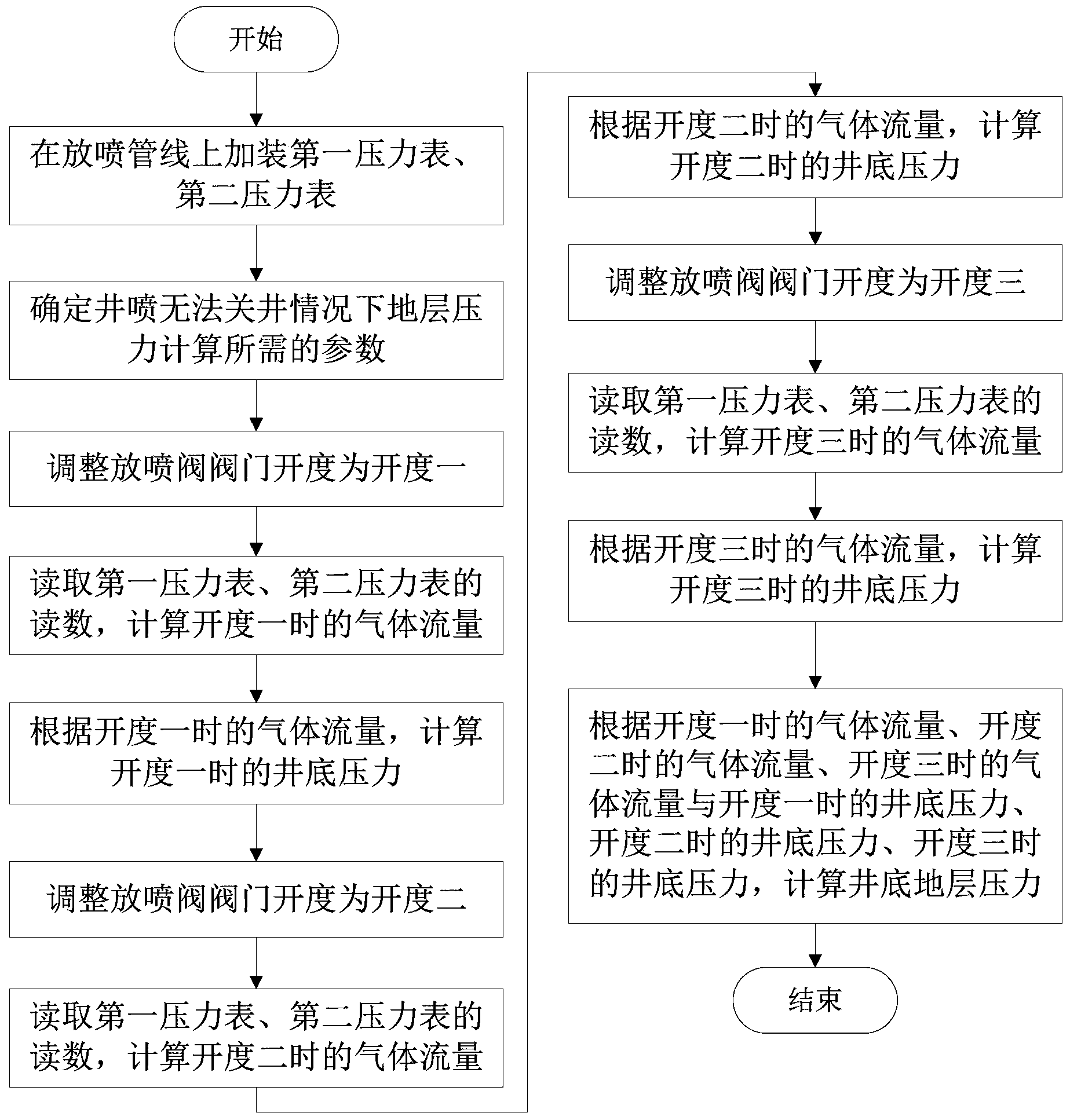

[0022] Such as figure 1 As shown, the method for determining formation pressure when the well blowout cannot be shut down includes the following steps:

[0023] 1. Install the first pressure gauge and the second pressure gauge on the discharge pipeline

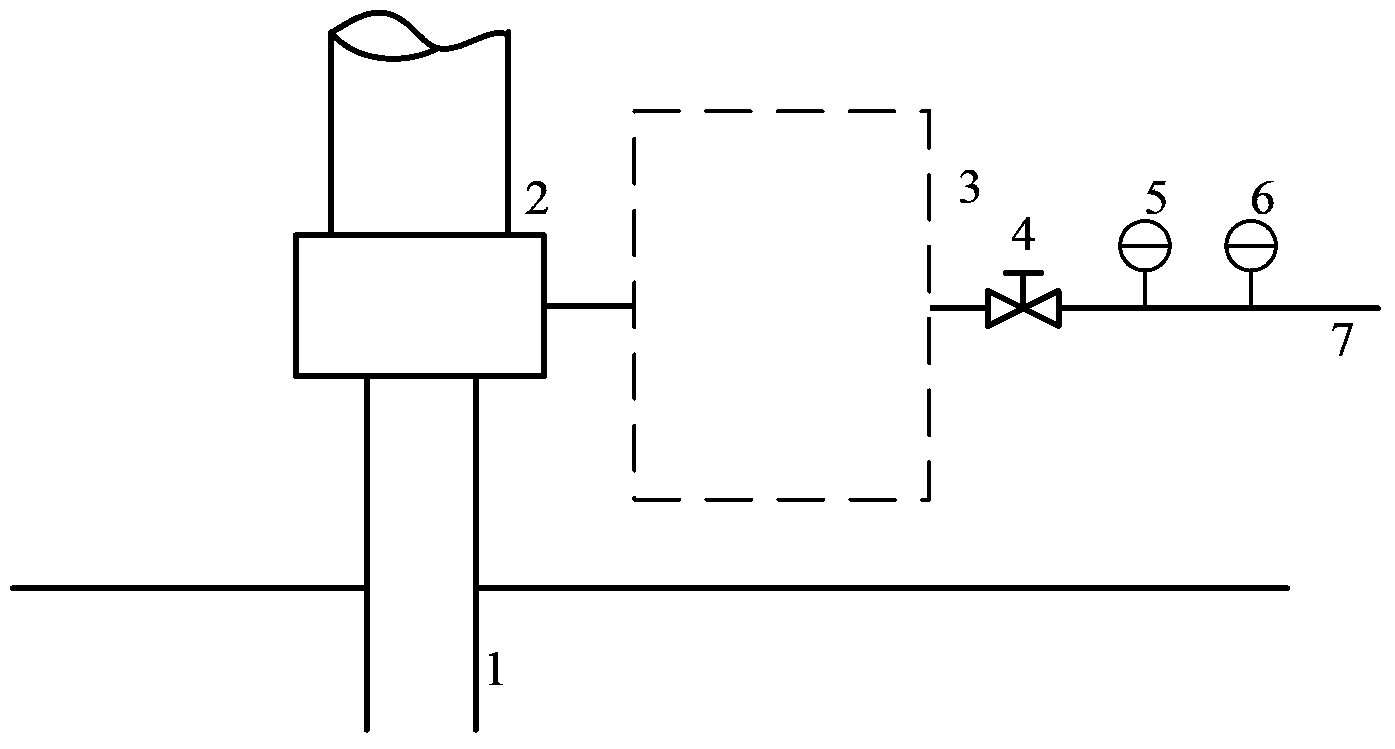

[0024] Such as figure 2 As shown, before drilling, the first pressure gauge 5 and the second pressure gauge 6 are installed on the discharge pipeline 7. The first pressure gauge 5 and the second pressure gauge 6 are separated by a certain distance, the distance is 10m; the first pressure gauge 5 Located between the discharge valve 4 and the second pressure gauge 6;

[0025] 2. Determine the parameters required for formation pressure calculation under the condition that the blowout cannot be shut down

[0026] Determine the required parameters according to site construction data, including: surface temperature, geothermal gradient, casing pressure, well structure, wellbore trajectory, drilling tool assembly, relative density of produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com