Laser welding clamp of sealed relay

A laser welding fixture and relay technology, applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of high cost, high labor intensity, low efficiency, etc., and achieve the goal of reducing disassembly, improving work efficiency, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

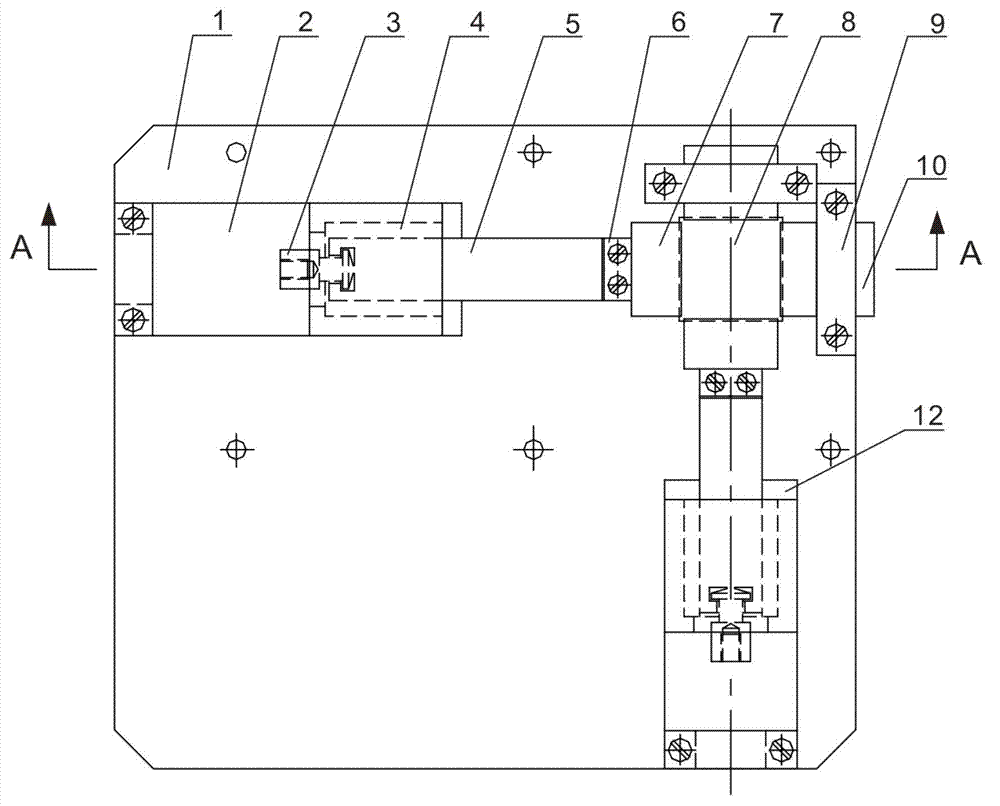

[0021] Embodiment: When the sealing cover needs to be welded on the sealed relay, select the matching sliding pressure plate 7 and the positioning pressure plate 10, and install them on the transfer block 6 and the support plate 11 respectively, and then fix them with screws, start the cylinder to pull the slider 5. Move to the hollow part in the support 2, so that the distance between the sliding platen 7 and the positioning platen 10 increases until the distance is greater than the size of the product to be clamped, then brake, and place the cover and the sealing relay on the pad On the block 8, after adjusting the position, tighten the screw on the positioning pressure plate 10 to complete the positioning; start the cylinder again, push the slider 5 to slide towards the support plate 11, until the sliding pressure plate 7 at the end of the slider 5 moves to the designated position and then closes Cylinder, tighten the screw on the sliding pressure plate 7, namely finish the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com