Pressurization simulation water depth testing device of sealing water tank and testing method

A technology for sealing water tanks and test devices, which is applied in the direction of liquid tightness measurement using liquid/vacuum, which can solve problems such as uneconomical, difficult, and complicated testing work, and achieve good effectiveness, economy, and low manufacturing costs. , the effect of simple structure

Inactive Publication Date: 2013-08-07

CHENGDU JINJIANG ELECTRONICS SYST ENG

View PDF6 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the usual practice is to use actual pools or rivers to test, that is, to put the sealing device into the pool or river, and lower it to the set depth, which requires out-of-door operation, and

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

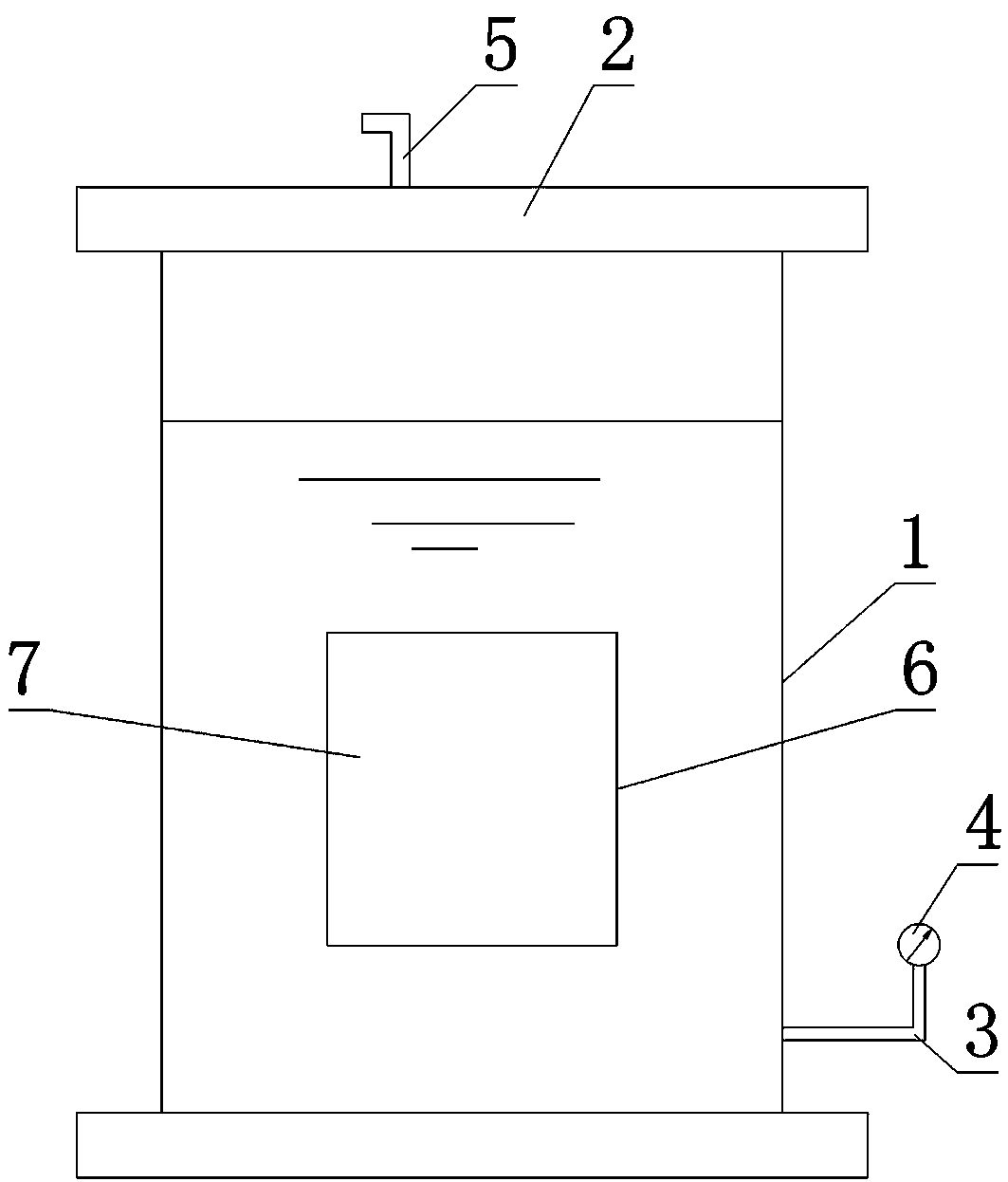

The invention discloses a pressurization simulation water depth testing device of a sealing water tank. The device comprises a tank body (1) with an upper opening, wherein a containing cavity is formed in the tank body (1); a tank cover (2) covers the tank body (1) and seals the containing cavity; a piezometer tube (3) is arranged on the bottom of the side wall of the tank body (1) and communicated with the containing cavity; a pressure gauge (4) is installed on the piezometer tube (3); and an inflation tube (5) is arranged on the seal cover and communicated with the containing cavity. The invention further discloses a testing method adopting the pressurization simulation water depth testing device of the sealing water tank. The device have the beneficial effects that the device can test various characteristic parameters of underwater equipment or devices at certain water depth pressure, overcomes the defects of adopting actual water depth verification and has good effectiveness and economy; and moreover, the device has the advantages of simple structure, low production cost, convenience in operation, economy, practicability, reliable test result and no field limitation.

Description

technical field [0001] The invention relates to the technical field of testing the sealing performance of underwater sealing devices, in particular to a pressure-charging simulated water depth test device and a test method for a sealed water tank. Background technique [0002] When carrying out the underwater sealing device and equipment test and acceptance test, it is necessary to place the underwater sealing device in the underwater environment under its working condition to meet the requirements of the test, acceptance test or detection, and conduct a deep water pressure test. At present, the usual practice is to use actual pools or rivers to test, that is, put the sealing device into the pool or river, and lower it to the set depth, which requires out-of-door operation, and the test work is complicated, difficult, and difficult to observe. Uneconomical. In particular, if the water depth to be tested reaches hundreds of meters, or even to the sea for testing, it is very ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M3/02

Inventor 赵辉陈茂源

Owner CHENGDU JINJIANG ELECTRONICS SYST ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com