Multiple-working-face parallel working process for shaft ground pre-grouting

A multi-face, parallel operation technology, applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve problems such as long well construction period, backward directional technology, single means, etc., to ensure quality, The effect of shortening the well construction period and speeding up the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] 1. Establish a grouting station

[0020] 2. The drilling rig starts drilling operations

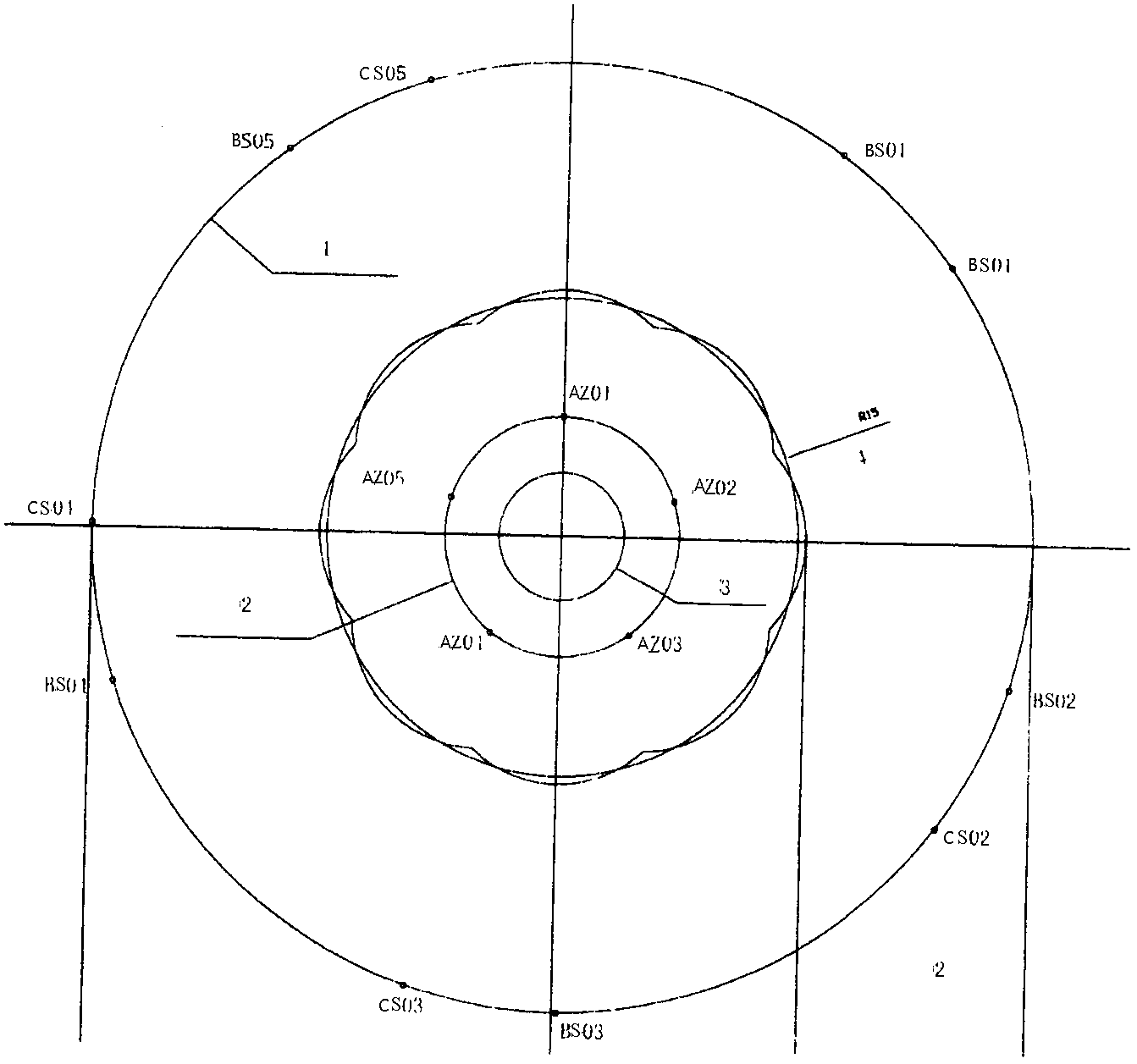

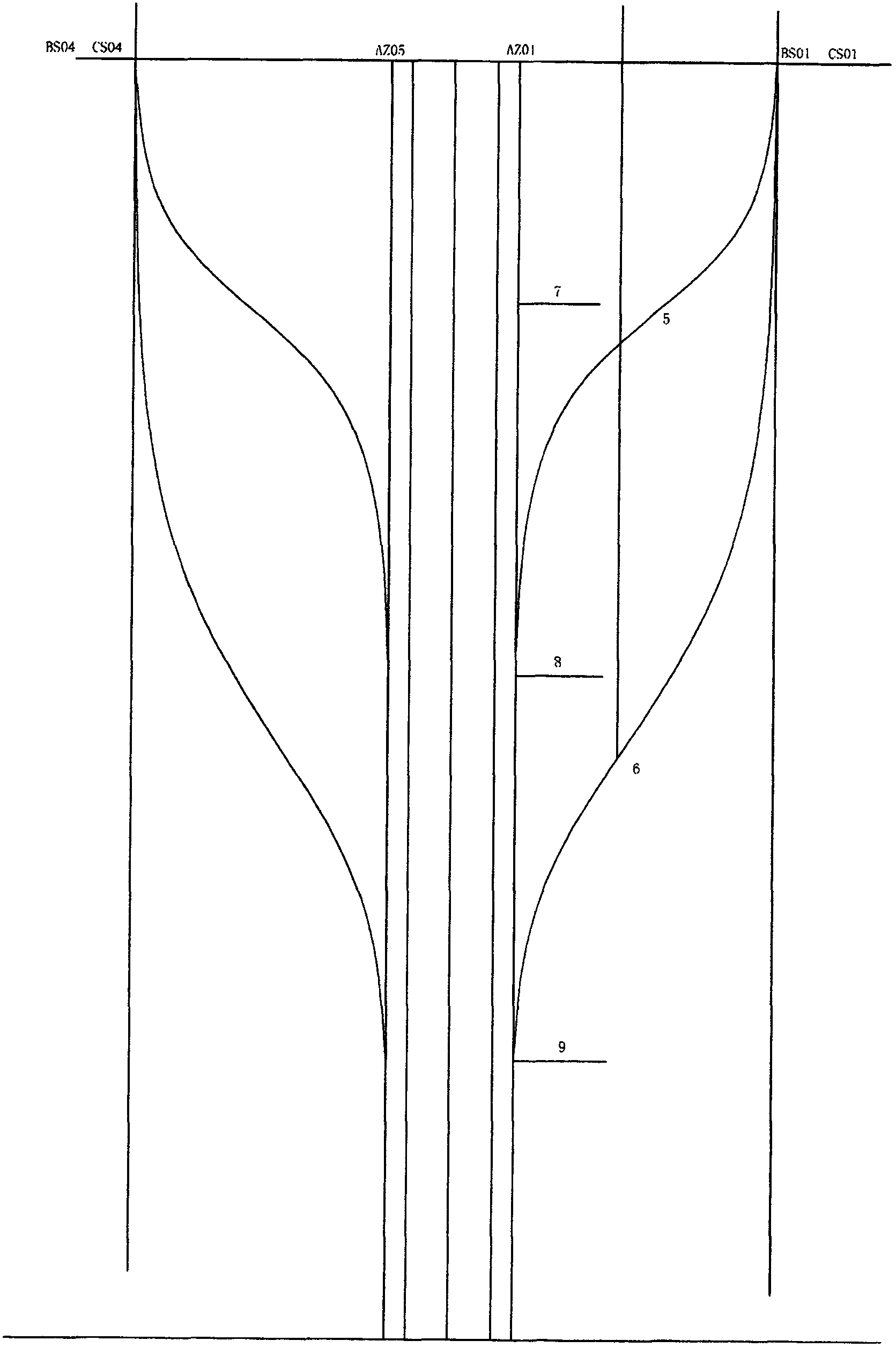

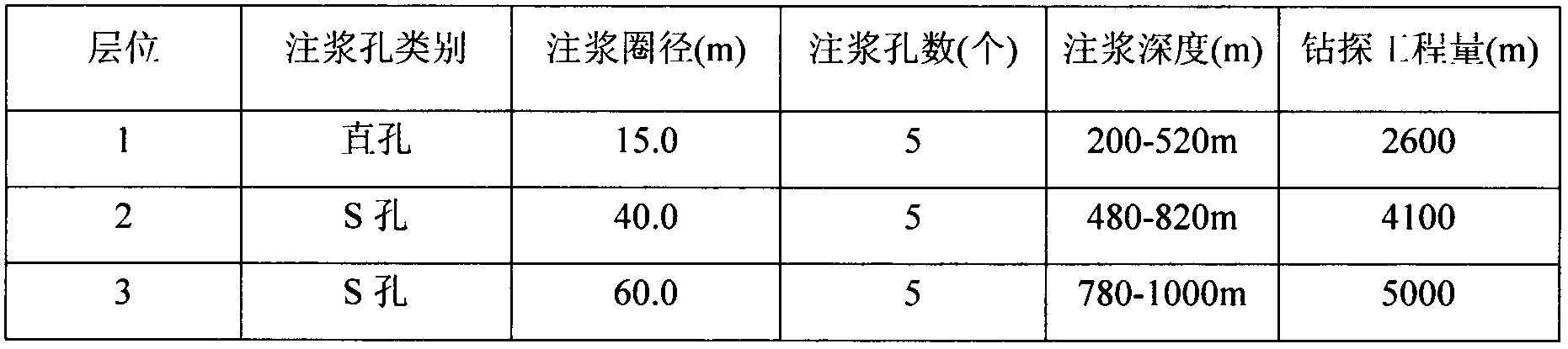

[0021] (1) Straight holes are arranged at the wellbore position. The initial depth of the grouting face of the first layer is 200m, and the final depth is 520m (40m with the grouting section of the second layer).

[0022] (2) The grouting holes in the second layer S are arranged at a distance of 40-60 meters away from the wellhead, and when the drilling depth reaches 480 meters, they are directed into the projection coordinates of the straight holes or evenly distributed at the projection of the diameter of the grouting circle of the straight holes. The initial grouting depth of the layer working face is 480 meters, and the final depth is 820 meters;

[0023] (3) The grouting holes of the third layer S are arranged 40-60 meters away from the wellhead, and when the drilling depth reaches 780 meters, they are directed into the projection coordinates of the straight holes or evenly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com